Nissan Rogue. Manual - part 167

C1109 POWER AND GROUND SYSTEM

BRC-79

< DTC/CIRCUIT DIAGNOSIS >

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

M

A

B

BRC

N

O

P

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair or replace malfunctioning components.

4.

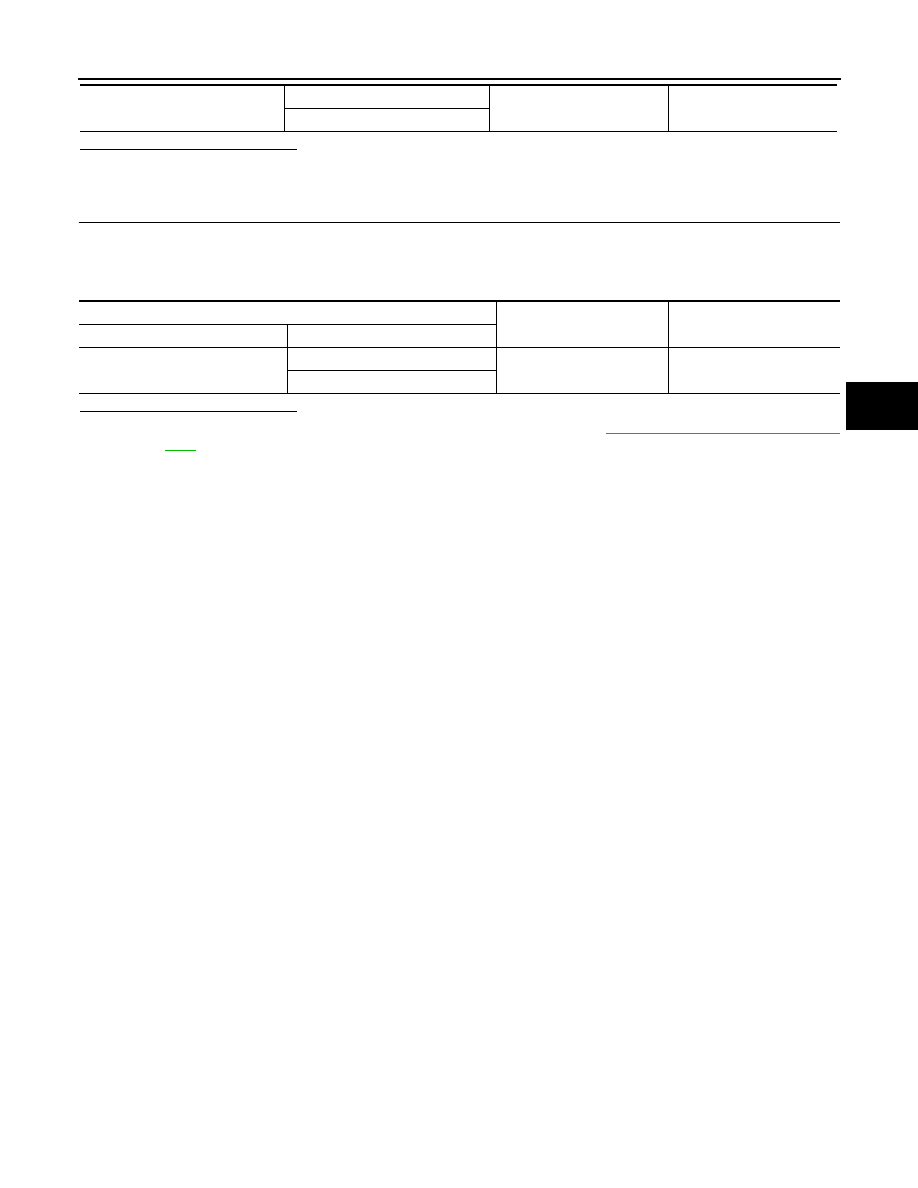

CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between ABS actuator and electric unit (control unit) connector E125 terminals 13, 38

and ground.

Is the inspection result normal?

YES

>> Replace ABS actuator and electric unit (control unit). Refer to

BRC-134, "Removal and Installa-

.

NO

>> Repair or replace malfunctioning components.

E125

1

—

Battery voltage

25

ABS actuator and electric unit (control unit)

—

Continuity

Connector

Terminal

E125

13

Ground

Yes

38