Nissan Maxima. Manual - part 929

POWER WINDOW SYSTEM

PWC-13

< SYSTEM DESCRIPTION >

[LH&RH FRONT WINDOW ANTI-PINCH]

C

D

E

F

G

H

I

J

L

M

A

B

PWC

N

O

P

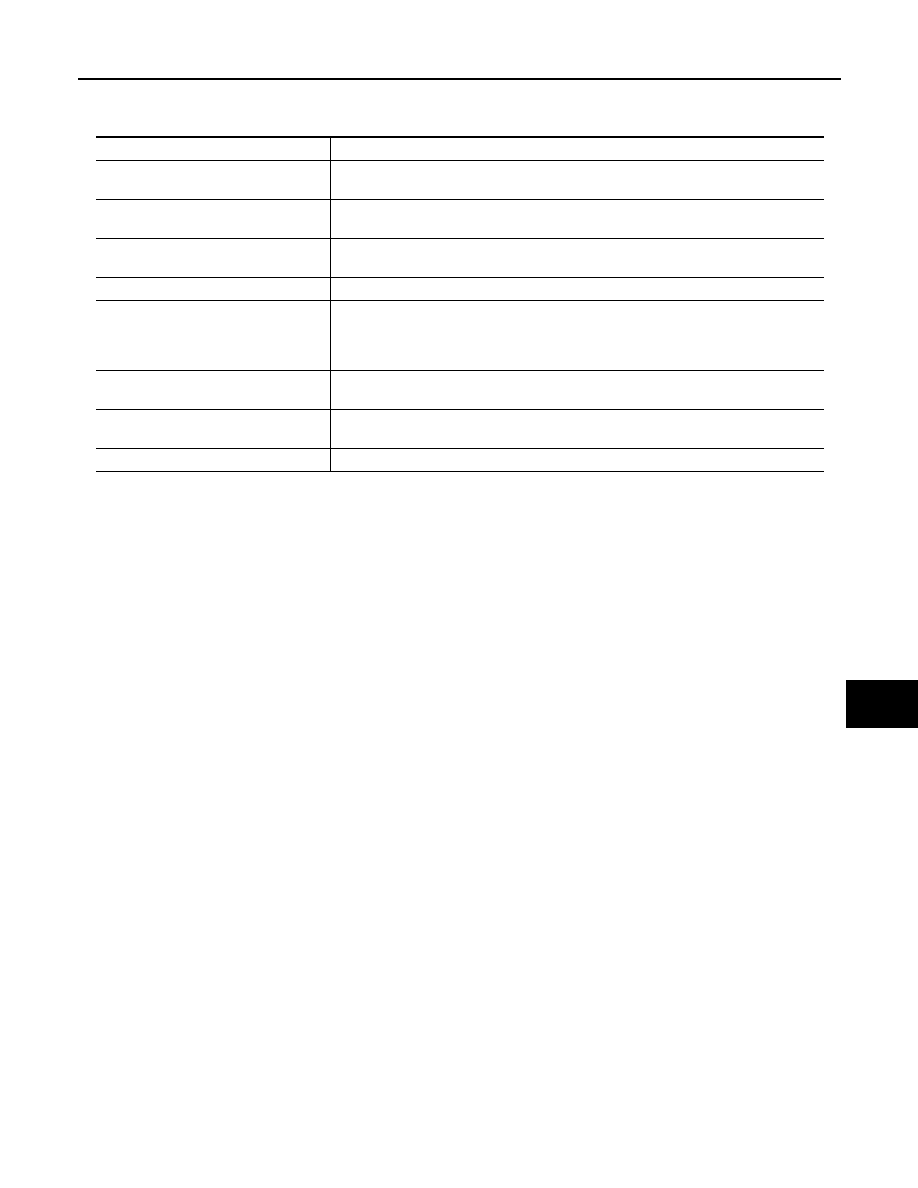

Component Description

INFOID:0000000010051193

Component

Function

BCM

• Supplies power supply to power window switch.

• Controls retained power.

Main power window and door lock/un-

lock switch

• Directly controls all power window motor of all doors.

• Controls anti-pinch operation of power window.

Power window and door lock/unlock

switch RH

• Controls power window motor of passenger door.

• Controls anti-pinch operation of power window.

Rear power window switch

• Controls power window motor of rear right and left doors.

Front power window motor

• Integrates the ENCODER POWER and WINDOW MOTOR.

• Starts operating with signals from main power window and door lock/unlock switch &

power window and door lock/unlock switch RH.

• Transmits power window motor rotation as a pulse signal to power window switch.

Rear power window motor

Starts operating with signals from main power window and door lock/unlock switch &

rear power window switch.

Front door lock assembly (key cylinder

switch)

Transmits operation condition of key cylinder switch to main power window and door

lock/unlock switch.

Front door switch

Detects door open/close condition and transmits to BCM.