Nissan Maxima. Manual - part 836

MA-18

< PERIODIC MAINTENANCE >

RECOMMENDED FLUIDS AND LUBRICANTS

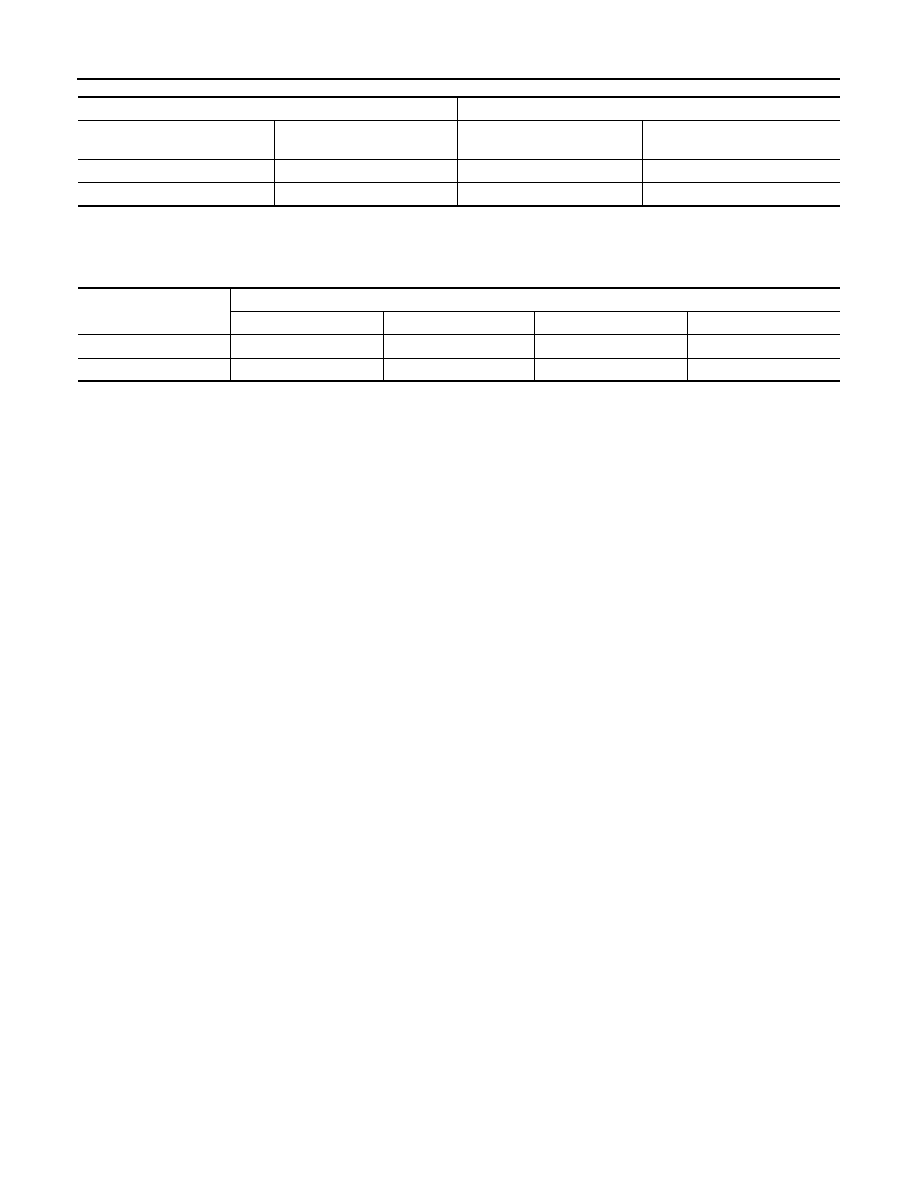

Coolant Mixture Ratios

When checking the engine coolant mixture ratio by the coolant hydrometer, use the chart below to correct your

hydrometer reading (specific gravity) according to coolant temperature.

Mixed Coolant Specific Gravity

Unit: specific gravity

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns could be caused by high pres-

sure fluid escaping from the radiator. Wait until the engine and radiator cool down.

CAUTION:

• When adding or replacing coolant, be sure to use only Genuine NISSAN Engine Coolant or equiva-

lent in its quality with the proper mixture ratio.

• The use of other types of engine coolant may damage your cooling system.

For outside temperatures down to:

Anti-freeze coolant mixture ratio

° C

° F

Genuine NISSAN Engine

Coolant or equivalent

Demineralized water or distilled

water

– 15

°

5

°

30 %

70 %

– 35

°

– 30

°

50 %

50 %

Engine coolant mixture

ratio

Coolant temperature

°C (°F)

15

° (59°)

25

° (77°)

35

° (95°)

45

° (113°)

30%

1.046 - 1.050

1.042 - 1.046

1.038 - 1.042

1.033 - 1.038

50%

1.076 - 1.080

1.070 - 1.076

1.065 - 1.071

1.059 - 1.065