Nissan Maxima. Manual - part 815

LAN-72

< DTC/CIRCUIT DIAGNOSIS >

[CAN SYSTEM (TYPE 2)]

MAIN LINE BETWEEN DLC AND HVAC CIRCUIT

DTC/CIRCUIT DIAGNOSIS

MAIN LINE BETWEEN DLC AND HVAC CIRCUIT

Diagnosis Procedure

INFOID:0000000009990306

1.

CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Disconnect the following harness connectors.

-

ECM

-

A/C auto amp.

4. Check the continuity between the data link connector and the A/C auto amp. harness connector.

Is the inspection result normal?

YES (Present error)>>Check CAN system type decision again.

YES (Past error)>>Error was detected in the main line between the data link connector and the A/C auto

amp.

NO

>> Repair the main line between the data link connector and the A/C auto amp.

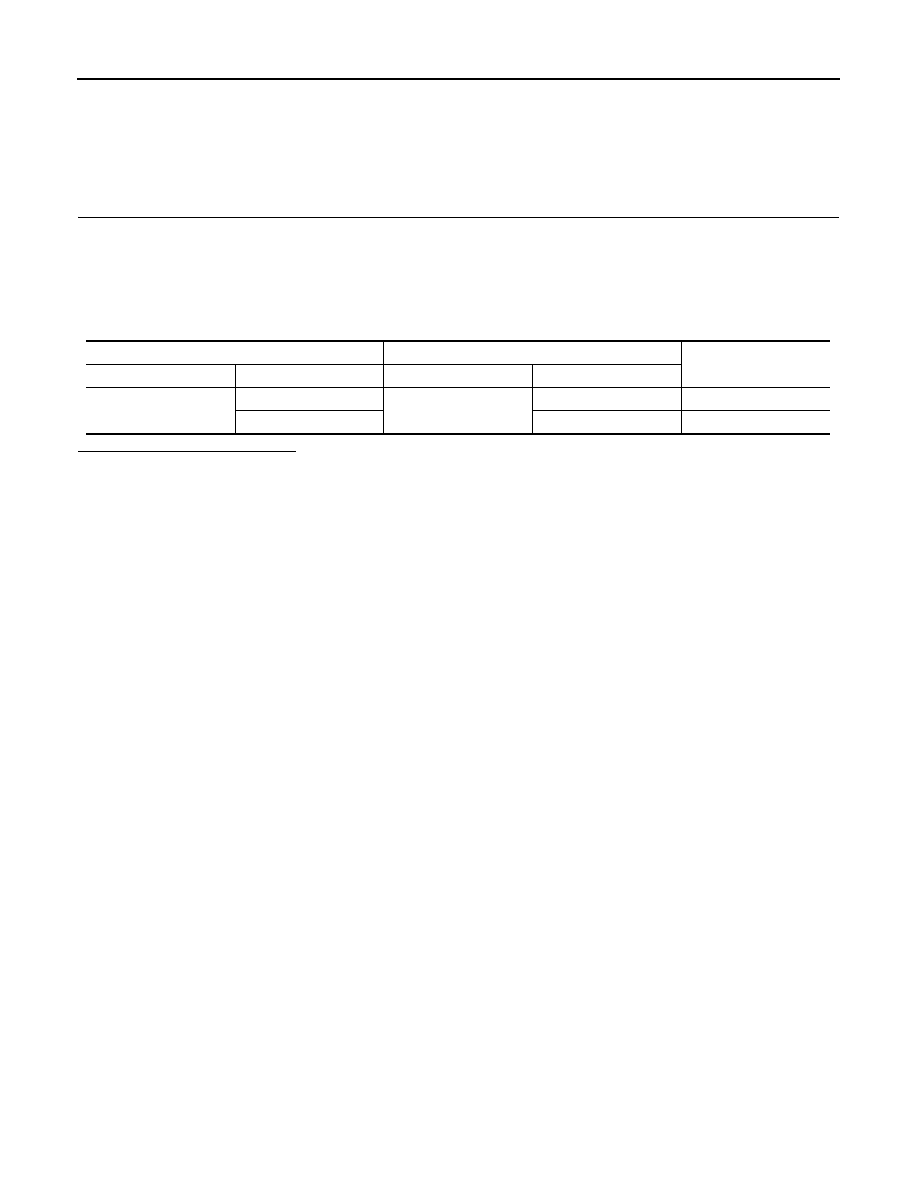

Data link connector

A/C auto amp. harness connector

Continuity

Connector No.

Terminal No.

Connector No.

Terminal No.

M22

6

M37

1

Existed

14

2

Existed