Nissan Maxima. Manual - part 806

LAN-36

< DTC/CIRCUIT DIAGNOSIS >

[CAN]

CAN COMMUNICATION SYSTEM

DTC/CIRCUIT DIAGNOSIS

CAN COMMUNICATION SYSTEM

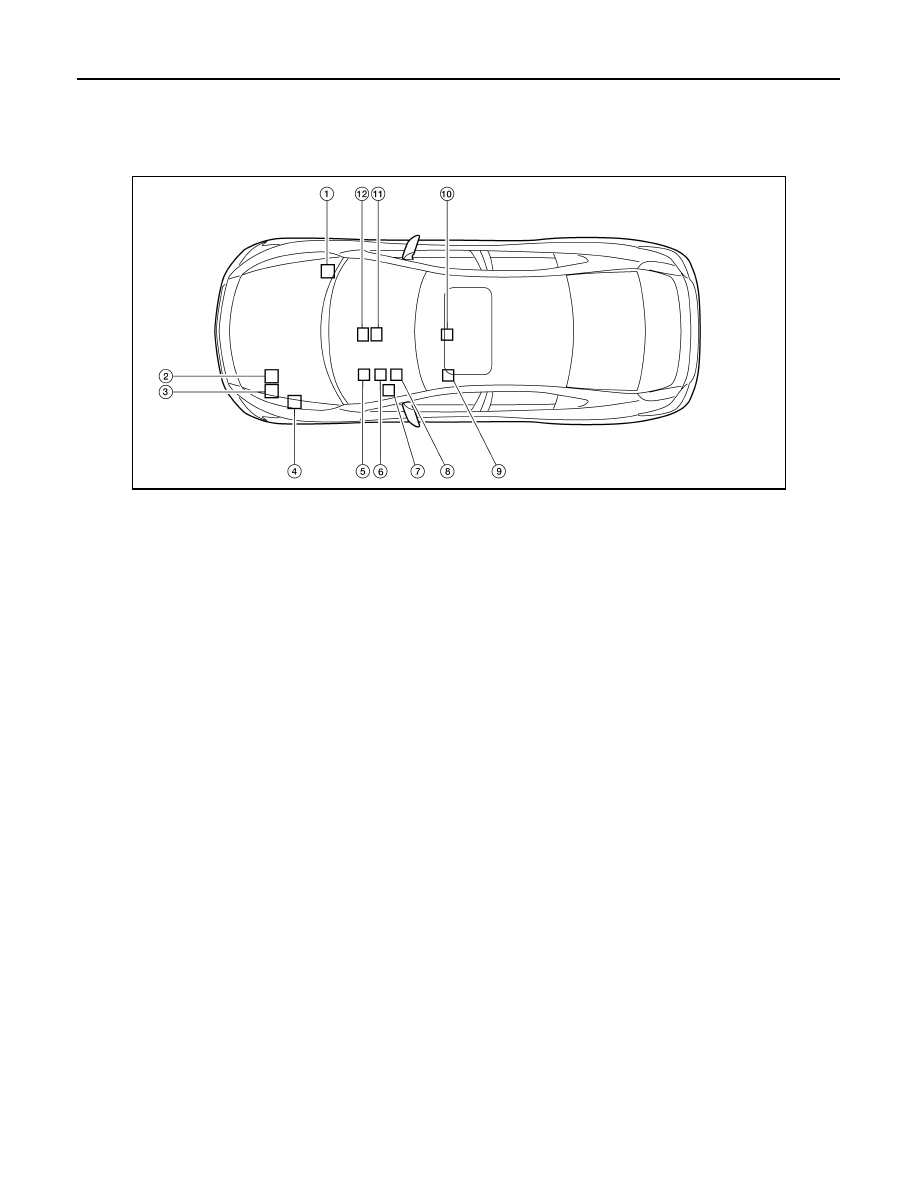

Component Parts Location

INFOID:0000000009471929

AWMIA1101ZZ

1.

ABS actuator and electric unit (con-

trol unit) E26

2.

TCM F15

3.

ECM E10

4.

IPDM E/R E17

5.

BCM M19

6.

Combination meter M24

7.

Data link connector M22

8.

Steering angle sensor M53

9.

Driver seat control unit B203

10. Air bag diagnosis sensor unit M43

11. A/C auto amp. M37

12. AV control unit

M156: With BOSE audio system -

without navigation system

M163: With BOSE audio system -

with navigation system

M119: With MID audio system