Nissan Maxima. Manual - part 737

HAC-124

< SYSTEM DESCRIPTION >

[WITH MONOCHROME DISPLAY]

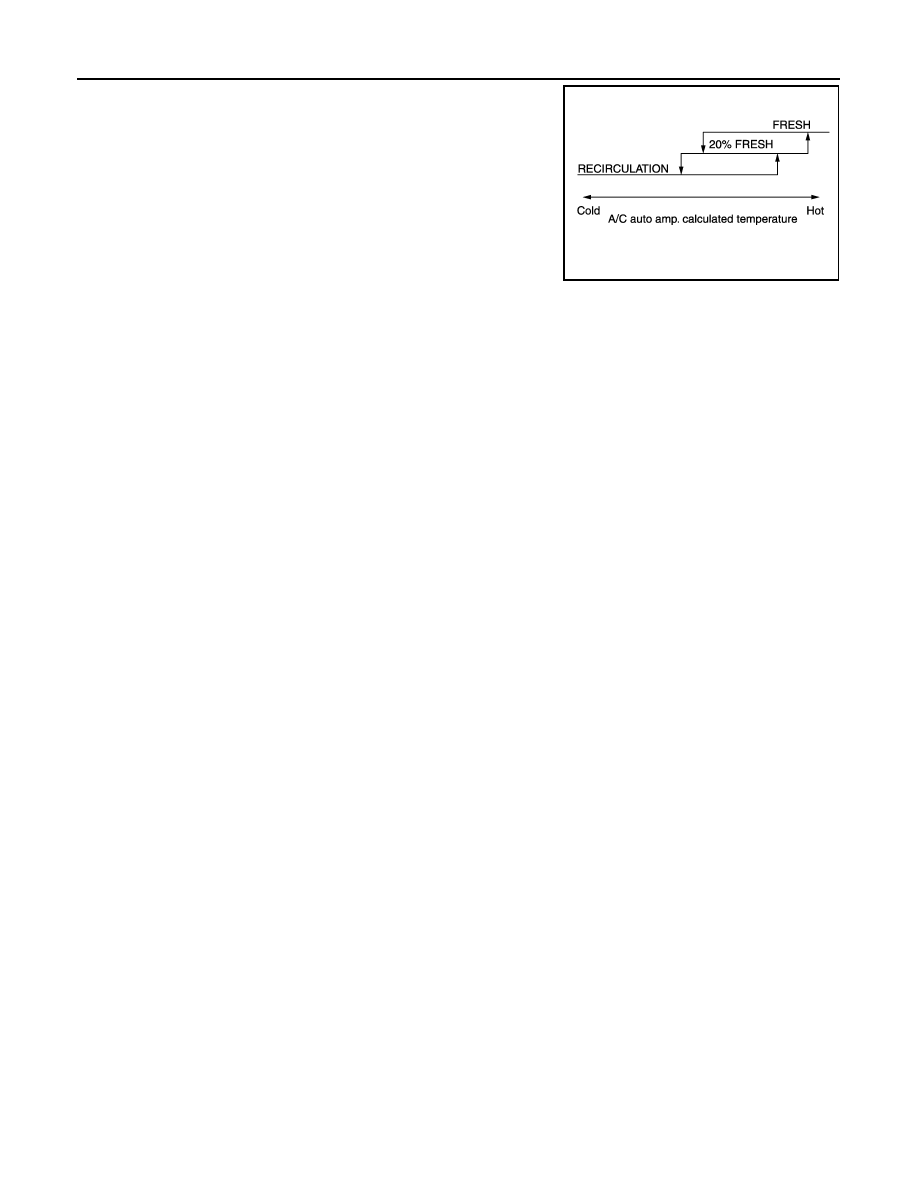

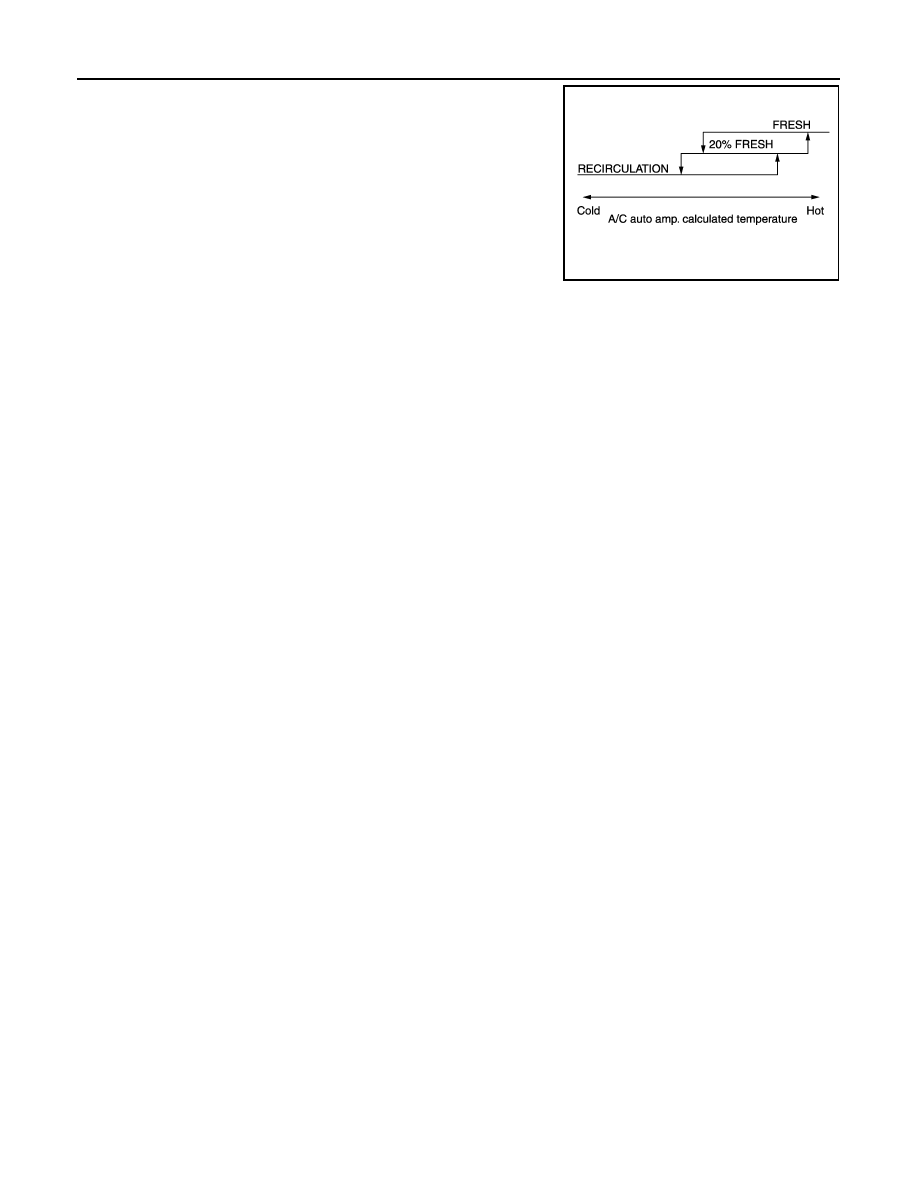

INTAKE DOOR CONTROL SYSTEM

Intake Door Control Specification

JPIIA0634GB

|

|

|

HAC-124 < SYSTEM DESCRIPTION > [WITH MONOCHROME DISPLAY] INTAKE DOOR CONTROL SYSTEM Intake Door Control Specification JPIIA0634GB |