Nissan Maxima. Manual - part 703

HA-38

< REMOVAL AND INSTALLATION >

COMPRESSOR

16. Remove the RH compressor bolts.

17. Remove the front compressor bolts using a power tool.

18. Disconnect the compressor wire harness clip from the compressor.

19. Remove the compressor.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• For installation, tighten the compressor bolts in the order as shown.

• Do not reuse O-rings.

• Apply A/C oil to the O-rings of the low-pressure flexible hose and high-pressure flexible hose for

installation.

• After charging the A/C refrigerant, check for leaks. Refer to

.

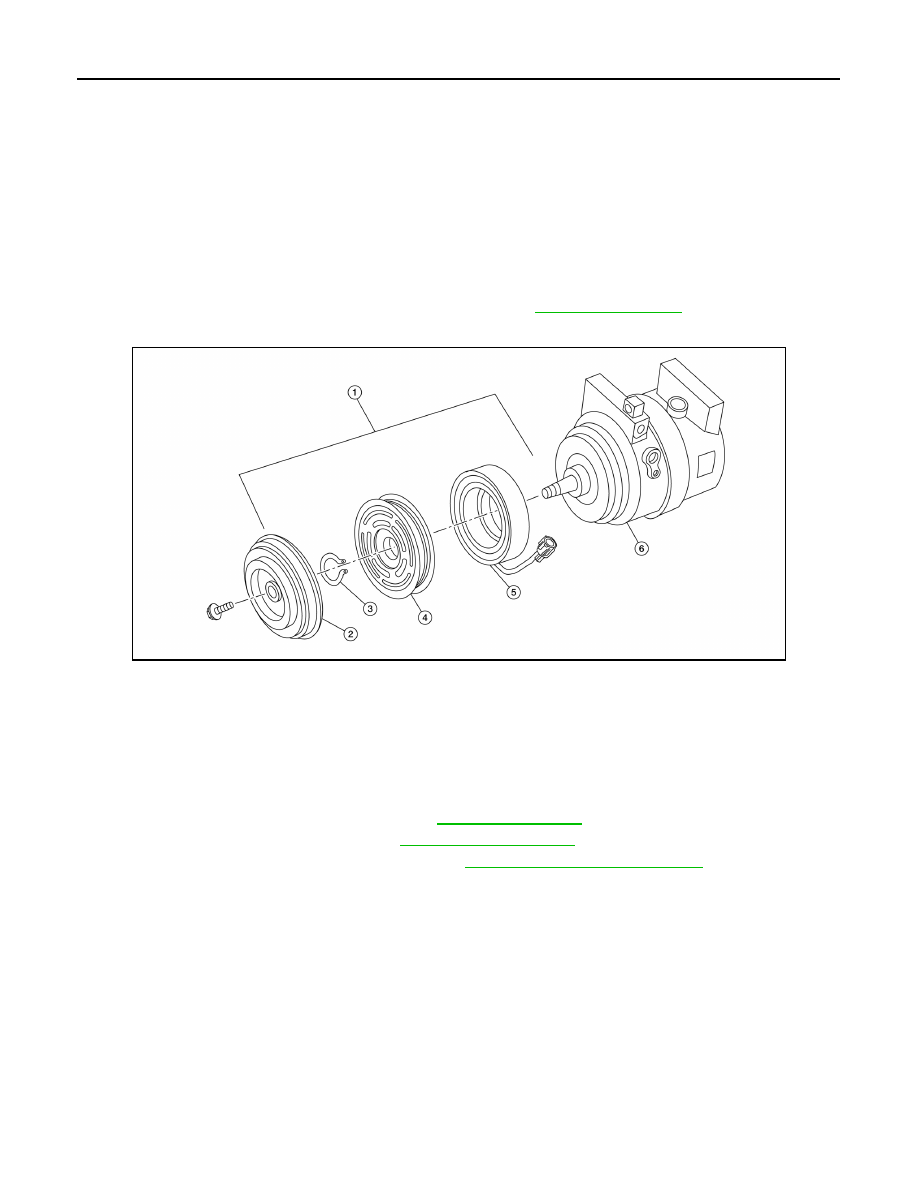

Removal and Installation for Compressor Clutch

INFOID:0000000009465945

NOTE:

Illustrations shown with the compressor out of the vehicle are for clarity, it is not necessary to remove the com-

pressor.

REMOVAL

1. Remove the front wheel and tire (RH). Refer to

2. Remove the engine under cover. Refer to

.

3. Release the drive belt from the A/C pulley. Refer to

EM-14, "Removal and Installation"

.

4. Reposition the power steering line aside, do not disconnect the power steering line.

5. Remove the center bolt by holding the clutch disc steady using a suitable tool.

6. Remove the clutch disc and shims.

CAUTION:

Retain all the shims for installation.

ALIIA0487ZZ

1.

Magnetic clutch assembly

2.

Clutch disk

3.

Snap ring

4.

Pulley

5.

Magnet coil

6.

Compressor