Nissan Maxima. Manual - part 508

EC-516

< DTC/CIRCUIT DIAGNOSIS >

[VQ35DE]

REFRIGERANT PRESSURE SENSOR

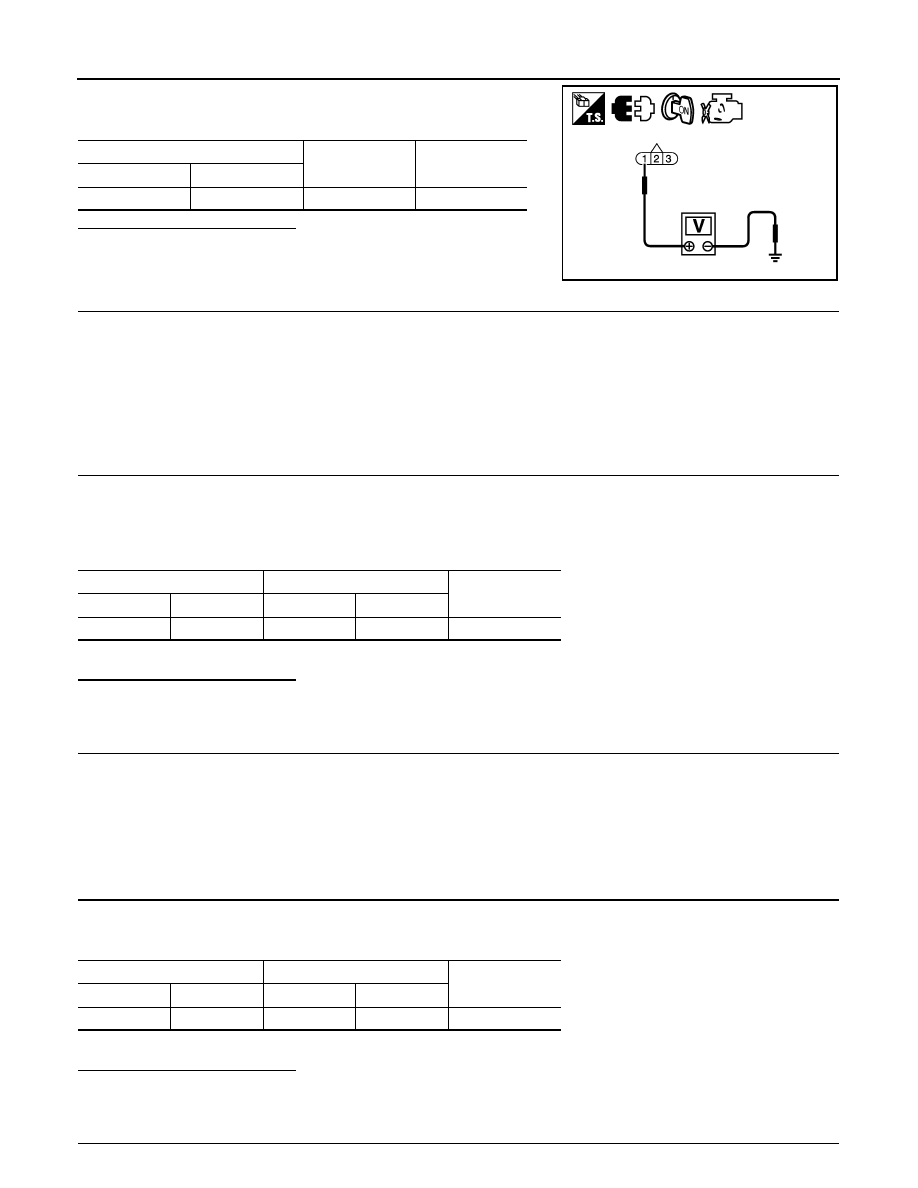

3. Check the voltage between refrigerant pressure sensor harness

connector and ground.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> GO TO 3.

3.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E3, F1

• Junction block connectors E44, E45

• IPDM E/R harness connectors E18, E201

• Harness for open or short between ECM and refrigerant pressure sensor

>> Repair open circuit, short to ground or short to power in harness or connectors.

4.

CHECK REFRIGERANT PRESSURE SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between refrigerant pressure sensor harness connector and ECM harness connec-

tor.

4. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> GO TO 5.

5.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E3, F1

• IPDM E/R harness connectors E18, E201

• Harness for open or short between ECM and refrigerant pressure sensor

>> Repair open circuit, short to ground or short to power in harness or connectors.

6.

CHECK REFRIGERANT PRESSURE SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check the continuity between refrigerant pressure sensor harness connector and ECM harness connec-

tor.

2. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 8.

NO

>> GO TO 7.

7.

DETECT MALFUNCTIONING PART

Refrigerant pressure sensor

Ground

Voltage (V)

Connector

Terminal

E219

1

Ground

Approx. 5

JMBIA1619ZZ

Refrigerant pressure sensor

ECM

Continuity

Connector

Terminal

Connector

Terminal

E219

3

F13

40

Existed

Refrigerant pressure sensor

ECM

Continuity

Connector

Terminal

Connector

Terminal

E219

2

F13

39

Existed