Nissan Maxima. Manual - part 240

BR-28

< REMOVAL AND INSTALLATION >

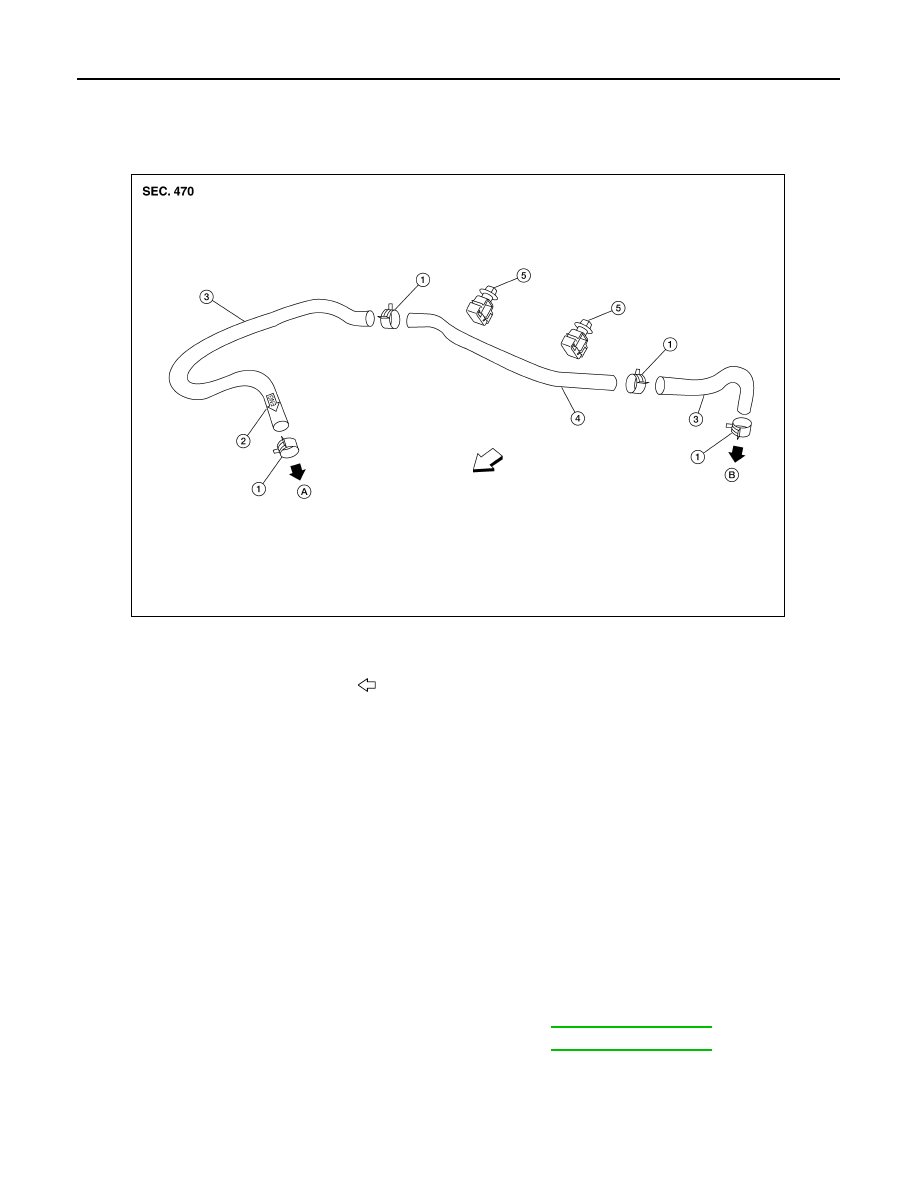

VACUUM LINES

VACUUM LINES

Exploded View

INFOID:0000000009466599

Removal and Installation

INFOID:0000000009466600

REMOVAL

1. Disconnect the vacuum hose from the brake booster.

2. Disconnect the vacuum hose from the intake manifold.

3. Release the clips and remove the vacuum pipe with the vacuum hoses attached.

4. Remove the vacuum hoses from the vacuum pipe.

INSPECTION AFTER REMOVAL

Visual Inspection

Check for correct installation, damage and deterioration of the vacuum hoses and pipe.

Valve Air-tightness Check

• Connect a suitable tool (hand vacuum pump) at each end of the vacuum hose to inspect the check valve

operation.

• Replace the vacuum hose component or check valve if out of specification.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

1.

Clamp

2.

Installation arrow

3.

Vacuum hose

4.

Vacuum pipe

5.

Clip

A. To intake manifold

B. To brake booster

Front

AWFIA0436ZZ

Vacuum applied at booster end

: Refer to

Vacuum applied at intake manifold end

: Refer to