Content .. 1127 1128 1129 1130 ..

Nissan Maxima. Manual - part 1129

STC-22

< UNIT REMOVAL AND INSTALLATION >

EPS CONTROL UNIT

UNIT REMOVAL AND INSTALLATION

EPS CONTROL UNIT

Removal and Installation

INFOID:0000000009466568

REMOVAL

1. Disconnect negative battery terminal. Refer to

PG-67, "Removal and Installation (Battery)"

.

2. Remove audio display unit. Refer to

AV-73, "Removal and Installation"

(BASE AUDIO),

(BOSE W/MONOCHROME DISPLAY),

AV-481, "Removal and Installation"

(BOSE W/

COLOR DISPLAY),

AV-652, "Removal and Installation"

(BOSE W/COLOR DISPLAY W/NAVIGATION).

3. Remove automatic drive position control unit (if equipped). Refer to

ADP-170, "Removal and Installation"

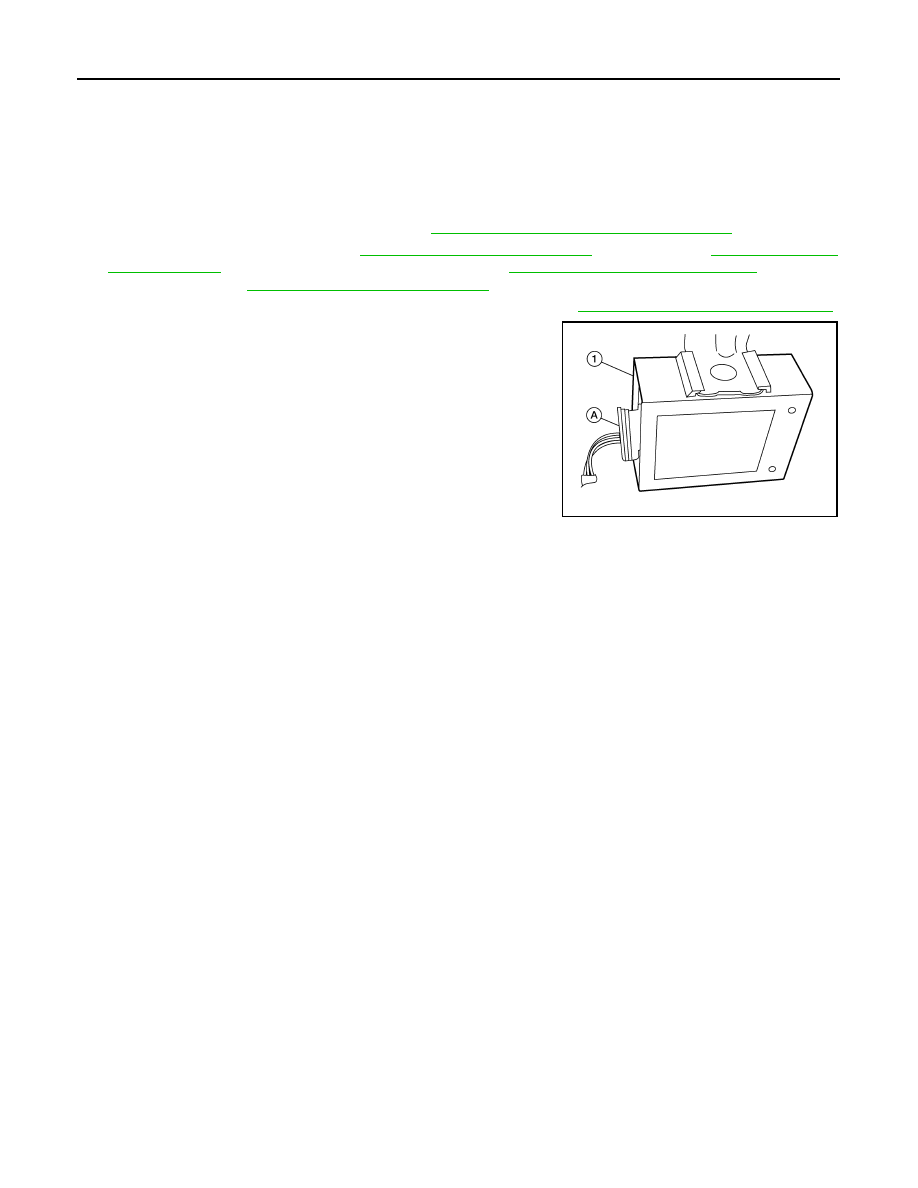

4. Remove EPS control unit (1) from the bracket.

5. Disconnect EPS control unit harness connector (A) and remove

the EPS control unit (1).

INSTALLATION

Installation is in the reverse order of removal.

ALGIA0040ZZ