Nissan Altima HL32 Hybrid. Manual - part 834

MWI

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

MWI-123

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

M

B

A

O

P

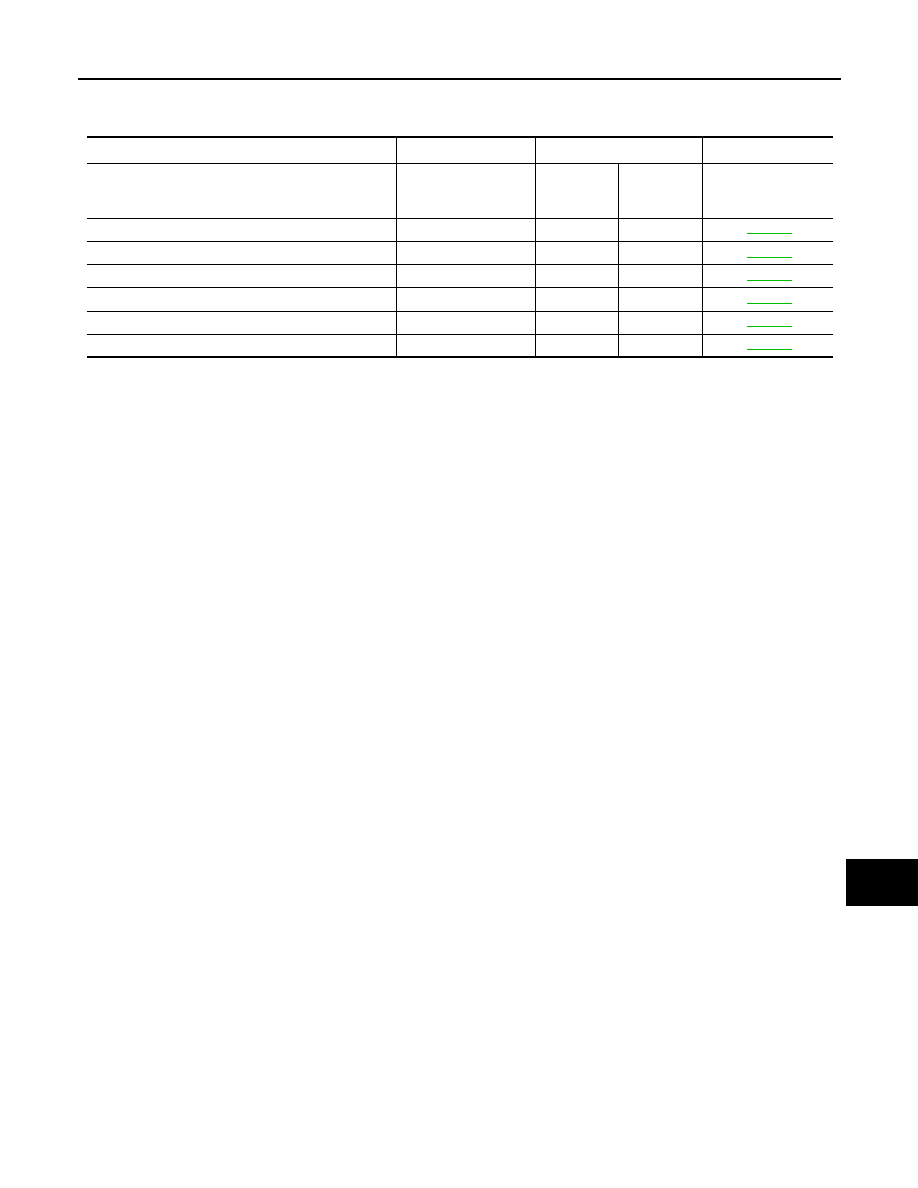

DTC Index

INFOID:0000000004501266

NOTE:

The details of TIME display are as follows.

• CRNT: The malfunctions that are detected now

• 1 - 39: The number is indicated when it is normal at present and a malfunction was detected in the past. It

increases like 0

→ 1 → 2 ··· 38 → 39 after returning to the normal condition whenever IGN OFF → ON. It is

fixed to 39 until the self-diagnosis results are erased if it is over 39. It returns to 0 when a malfunction is

detected again in the process.

CONSULT-III display

Fail-safe

TIME

NOTE

Refer to

No DTC is detected.

further testing

may be required.

—

—

—

—

U1000: CAN COMM CIRCUIT

×

CRNT

1 – 39

B2098: IGN RELAY ON

×

CRNT

1 – 39

B2099: IGN RELAY OFF

—

CRNT

1 – 39

B2108: STRG LCK RELAY ON

—

CRNT

1 – 39

B2109: STRG LCK RELAY OFF

—

CRNT

1 – 39

B210A: STRG LCK STATE SW

—

CRNT

1 – 39