Nissan Altima HL32 Hybrid. Manual - part 651

P0A90-509

HBC-353

< COMPONENT DIAGNOSIS >

D

E

F

G

H

I

J

K

L

M

A

B

HBC

N

O

P

P0A90-509

Description

INFOID:0000000004211990

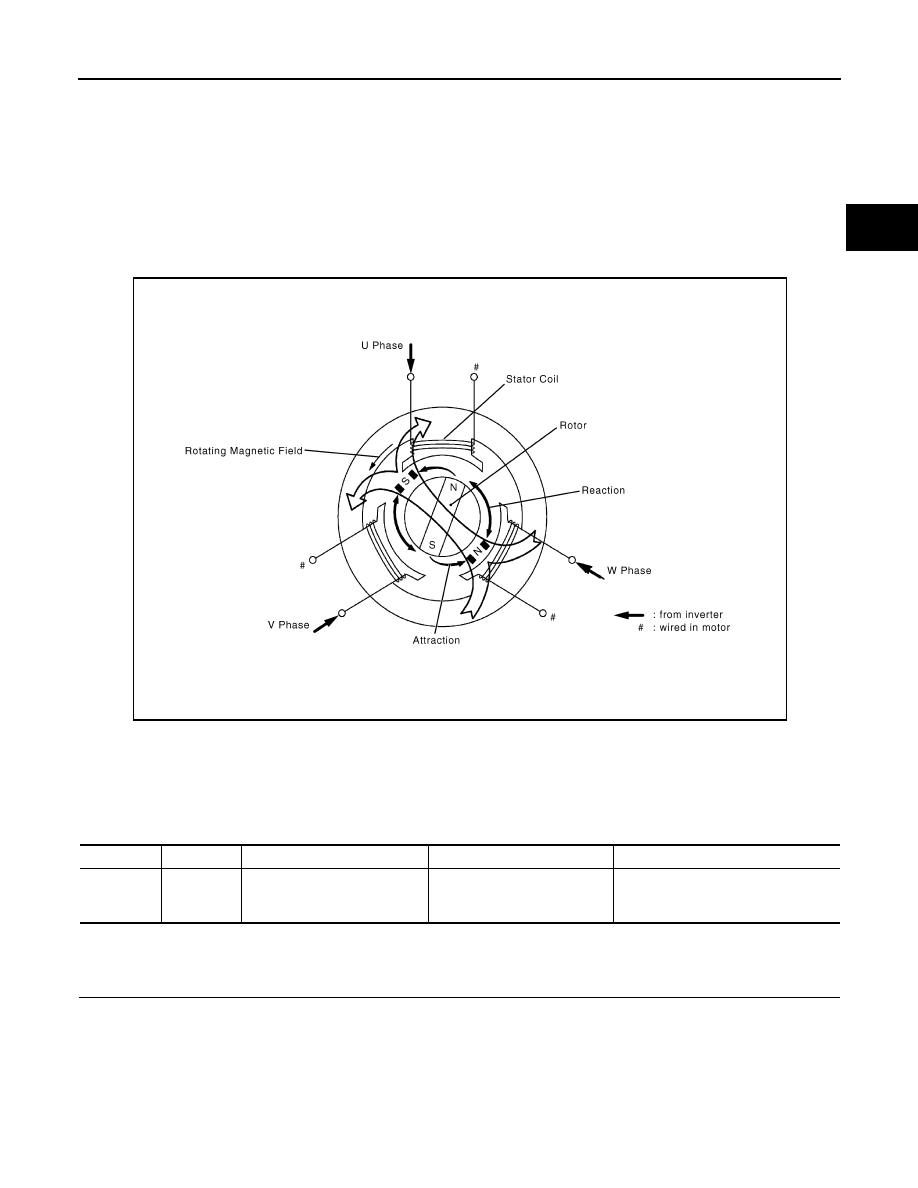

When three-phase alternating current flows through the three-phase windings of the stator coil, a rotating

magnetic field is generated in MG2. The system controls the rotation of the magnetic field in accordance with

the rotating position and speed of the rotor. As a result, the permanent magnets provided in the rotor are

pulled in the direction of rotation, generating torque. The generated torque is almost proportional to the

amount of current. The system controls MG2 speed by regulating the frequency of the alternating current. Fur-

thermore, the system properly controls the rotating magnetic field and the angle of the rotor magnets in order

to generate high torque in an efficient manner, even at high speeds.

DTC Logic

INFOID:0000000004211991

DTC DETECTION LOGIC

The MG ECU monitors the MG2 system. If the MG ECU detects a malfunction of the MG2 system, the hybrid

vehicle control ECU will illuminate the MIL and set a DTC.

Diagnosis Procedure

INFOID:0000000004211992

1.

PRECONDITIONING

• Before inspecting the high-voltage system or disconnecting the low voltage connector of the inverter with

converter assembly, take safety precautions such as wearing insulated gloves and removing the service

plug grip to prevent electrical shocks. After removing the service plug grip, put it in your pocket to prevent

other technicians from accidentally reconnecting it while you are working on the high-voltage system.

• After disconnecting the service plug grip, wait for at least 10 minutes before touching any of the high-voltage

connectors or terminals.

• Waiting for at least 10 minutes is required to discharge the high-voltage capacitor inside the inverter with

converter assembly.

JMCIA0101GB

DTC No.

INF code

Trouble diagnosis name

DTC detecting condition

Possible cause

P0A90

509

Drive Motor “A” Performance

Motor system malfunction

• Wire harness or connector

• Hybrid transaxle

• Inverter with converter assembly