Nissan Altima HL32 Hybrid. Manual - part 619

P0A78-113

HBC-225

< COMPONENT DIAGNOSIS >

D

E

F

G

H

I

J

K

L

M

A

B

HBC

N

O

P

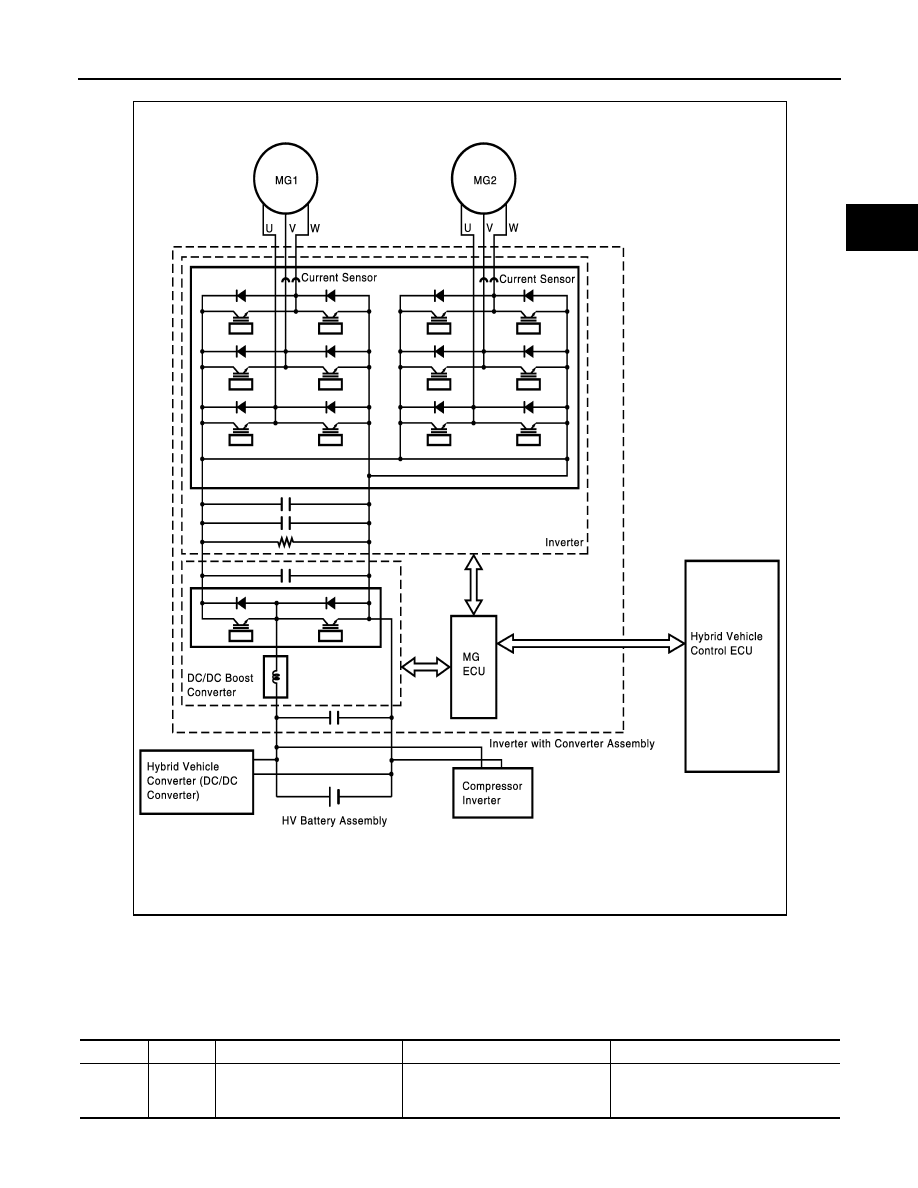

The MG ECU monitors the inverter voltage and detects malfunctions.

DTC Logic

INFOID:0000000004211907

DTC DETECTION LOGIC

If MG ECU detects overheat or circuit malfunction of the traction motor inverter, the inverter assembly trans-

mits this information via the traction motor inverter fail signal line.

JMCIA0099GB

DTC No.

INF Code

Trouble diagnosis name

DTC detecting condition

Possible cause

P0A78

113

Drive Motor “A” Inverter Perfor-

mance

Motor inverter fail signal detection

(overcurrent due to system mal-

function)

• Wire harness or connector

• Hybrid transaxle

• Inverter with converter assembly