Nissan Altima HL32 Hybrid. Manual - part 512

B2651, B2652 ELECTRIC COMPRESSOR

HAC-69

< COMPONENT DIAGNOSIS >

[AUTOMATIC AIR CONDITIONER]

C

D

E

F

G

H

J

K

L

M

A

B

HAC

N

O

P

B2651, B2652 ELECTRIC COMPRESSOR

Description

INFOID:0000000004215356

The temperature sensor of the electric compressor detects inverter temperature. If the temperature exceeds

the maximum, the electric compressor stops compressor operation, and this DTC will be output. The output

DTC of B2651 are memorized only present trouble. On B2652, compressor control may not resume unless the

ignition switch is turned OFF and waiting for 10 minutes.

DTC Logic

INFOID:0000000004215357

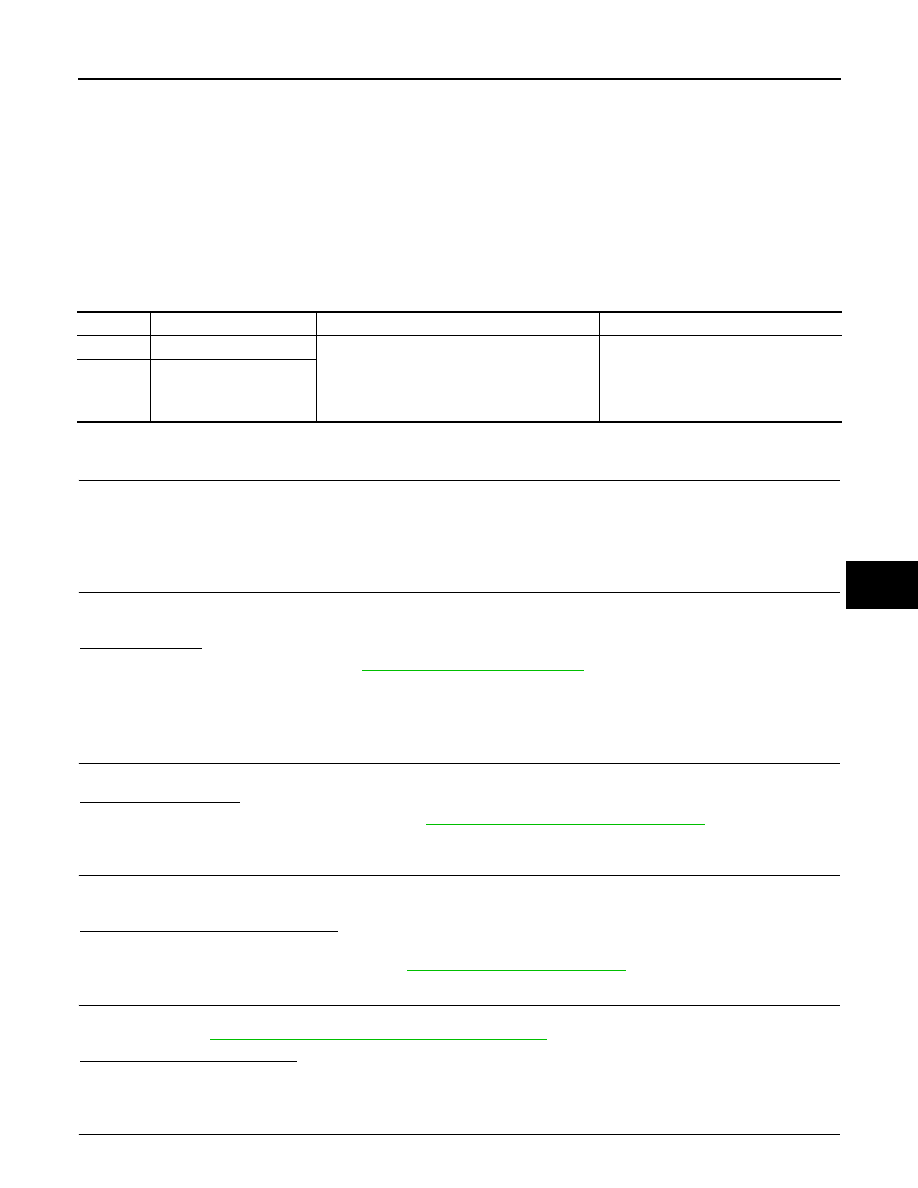

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

>> GO TO 2.

2.

PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON (READY) and wait at least 5 seconds.

2. Check DTC.

Is DTC detected?

YES

>> Go to Diagnosis Procedure.

NO

>> END.

Diagnosis Procedure

INFOID:0000000004215358

1.

CHECK CAN COMMUNICATION SYSTEM

Use the CONSULT-III to check if the CAN Communication System is functioning normally.

Is CAN DTC detected?

YES

>> Check CAN communication. Refer to

LAN-16, "Trouble Diagnosis Flow Chart"

.

NO

>> GO TO 2.

2.

PERFORM ACTIVE TEST

1. Turn ignition switch ON (READY).

2. Perform “FAN DUTY CONTROL” in “ACTIVE TEST” mode with CONSULT-III.

Does cooling fan operates smoothly?

YES

>> GO TO 3.

NO

>> Go to cooling fan system. Refer to

3.

CHECK REFRIGERANT CYCLE PRESSURE

Connect refrigerant recovery/recycling recharging equipment to the vehicle and check the refrigerant cycle

HA-21, "HFC-134a (R-134a) Service Procedure"

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Recharge refrigerant after repair or replace the parts according to the inspection results.

4.

CHECK DTC

DTC No.

Trouble Diagnosis Name

DTC Detecting Condition

Possible Cause

B2651

INV OVERHEAT L

• After READY and A/C ON

• Temperature in the inverter is outside the

specified range (temperature is too high), or

there is an open or short to ground in the tem-

perature sensor circuit.

• Cooling fan system

• Refrigerant volume

• Electric compressor

• CAN communication system

B2652

INV OVERHEAT S