Nissan Altima HL32 Hybrid. Manual - part 328

EC-296

< COMPONENT DIAGNOSIS >

[QR25DE]

P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

• Harness connectors B10, E29

• Harness for open or short between EVAP control system pressure sensor and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors.

10.

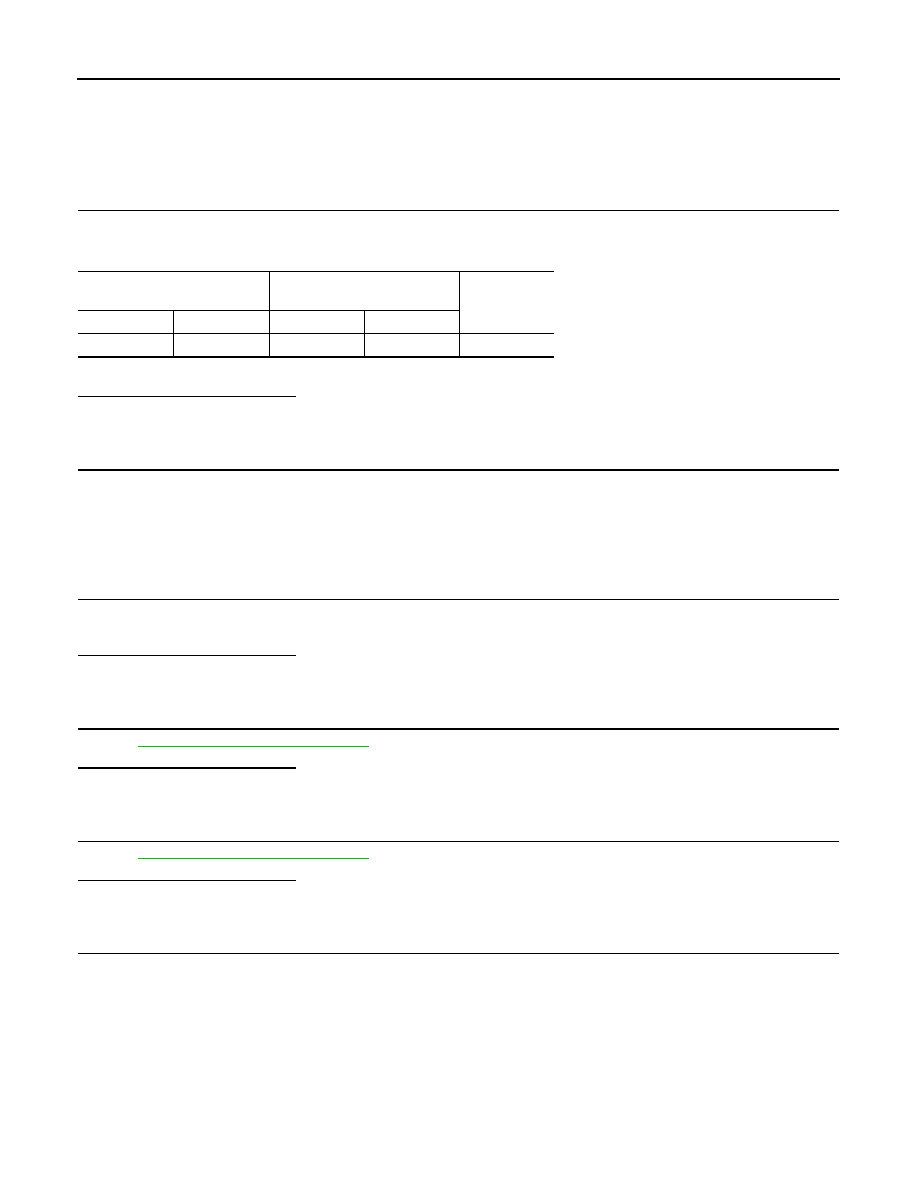

CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND

SHORT

1. Check the continuity between EVAP control system pressure sensor harness connector and ECM har-

ness connector.

2. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 12.

NO

>> GO TO 11.

11.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors B10, E29

• Harness for open or short between EVAP control system pressure sensor and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors.

12.

CHECK RUBBER TUBE

1. Disconnect rubber tube connected to EVAP canister vent control valve.

2. Check the rubber tube for clogging.

Is the inspection result normal?

YES

>> GO TO 13.

NO

>> Clean the rubber tube using an air blower, repair or replace rubber tube.

13.

CHECK EVAP CANISTER VENT CONTROL VALVE

EC-278, "Component Inspection"

Is the inspection result normal?

YES

>> GO TO 14.

NO

>> Replace EVAP canister vent control valve.

14.

CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-297, "Component Inspection"

Is the inspection result normal?

YES

>> GO TO 15.

NO

>> Replace EVAP control system pressure sensor.

15.

CHECK IF EVAP CANISTER SATURATED WITH WATER

1. Remove EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor

attached.

EVAP control system pressure

sensor

ECM

Continuity

Connector

Terminal

Connector

Terminal

B41

2

E10

86

Existed