Nissan Altima HL32 Hybrid. Manual - part 120

DIAGNOSIS SYSTEM (VDC/TCS/ABS CONTROL UNIT)

BRC-45

< FUNCTION DIAGNOSIS >

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

M

A

B

BRC

N

O

P

DIAGNOSIS SYSTEM (VDC/TCS/ABS CONTROL UNIT)

CONSULT-III Function

INFOID:0000000004212634

DIAGNOSIS SYSTEM

Description

When troubleshooting a vehicle with the diagnosis system, the only difference from the usual troubleshooting

procedure is connecting the CONSULT-III to the vehicle and reading various data output from the vehicle

′s

brake ECU.

The brake ECU records DTCs when the computer detects a malfunction in the computer itself or in its circuits.

To check for DTCs, activate the various actuators, and check the Freeze Frame Data and Data List.

1. Check the auxiliary battery voltage.

If the voltage is below 11 V, recharge the auxiliary battery before proceeding to the next step.

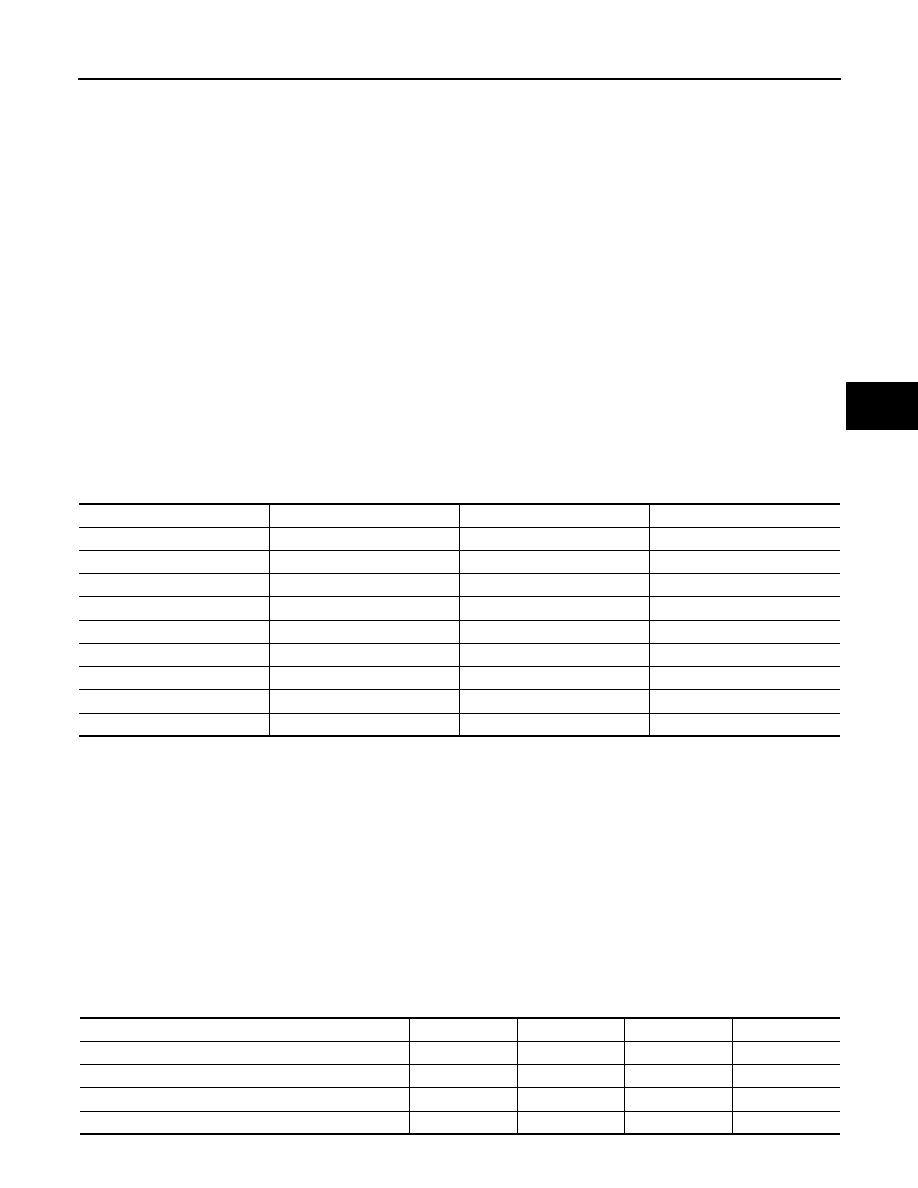

2. Check the DLC3.

The ECU uses ISO 15765-4 for communication. The terminal arrangement of the DLC3 complies with

SAE J1962 and matches the ISO 15765-4 format.

If the result is not as specified, the DLC3 may have a malfunction. Repair or replace the harness and con-

nector.

Verify the conditions listed in the table below.

*: Before measuring the resistance, leave the vehicle as is for at least 1 minute and do not operate the ignition switch, any other

switches or the doors.

NOTE:

• Connect the cable of the CONSULT-III to the DLC3, turn the ignition switch ON and attempt to use the tester.

If the display indicates that a communication error has occurred, there is a problem either with the vehicle or

with the tester.

• If communication is normal when the tester is connected to another vehicle, inspect the DLC3 on the original

vehicle.

• If communication is still not possible when the tester is connected to another vehicle, the problem may be in

the tester itself. CONSULT-III the Service Department listed in the tester operator

′s manual.

Diagnosis

1. If the brake ECU detects a malfunction, the ABS warning lamp, brake warning lamp, Electronically Con-

trolled Brake warning lamp, VDC warning lamp, and SLIP indicator lamp will come ON.

The table below indicates which lamps will come ON when there is a malfunction in a particular function.

×: Light ON –: Light OFF

Standard voltage : 11 to 14 V

Symbols (Terminal No.)

Terminal description

Condition

Specified condition

7 – 5

Bus “+” line

During transmission

Pulse generation

4 – Ground

Chassis ground

Always

Below 1

Ω

5 – Ground

Signal ground

Always

Below 1

Ω

16 – Ground

Battery positive

Always

11 to 14 V

6 – 14

CAN communication line

Ignition switch OFF*

54 to 69

Ω

6 – 4

CAN-H line

Ignition switch OFF*

200

Ω or higher

14 – 4

CAN-L line

Ignition switch OFF*

200

Ω or higher

6 – 16

CAN-H line

Ignition switch OFF*

6 k

Ω or higher

14 – 16

CAN-L line

Ignition switch OFF*

6 k

Ω or higher

Item / Trouble area

ABS

EBD

TCS

VDC

ABS warning lamp

×

×

—

—

Brake warning lamp

—

×

—

—

Electronically Controlled Brake warning lamp

×

×

—

—

VDC warning lamp

×

×

×

×