Content .. 1071 1072 1073 1074 ..

Nissan Altima HL32 Hybrid. Manual - part 1073

TM-10

< FUNCTION DIAGNOSIS >

[HYBRID TRANSAXLE: RE0F01H]

MECHANICAL SYSTEM

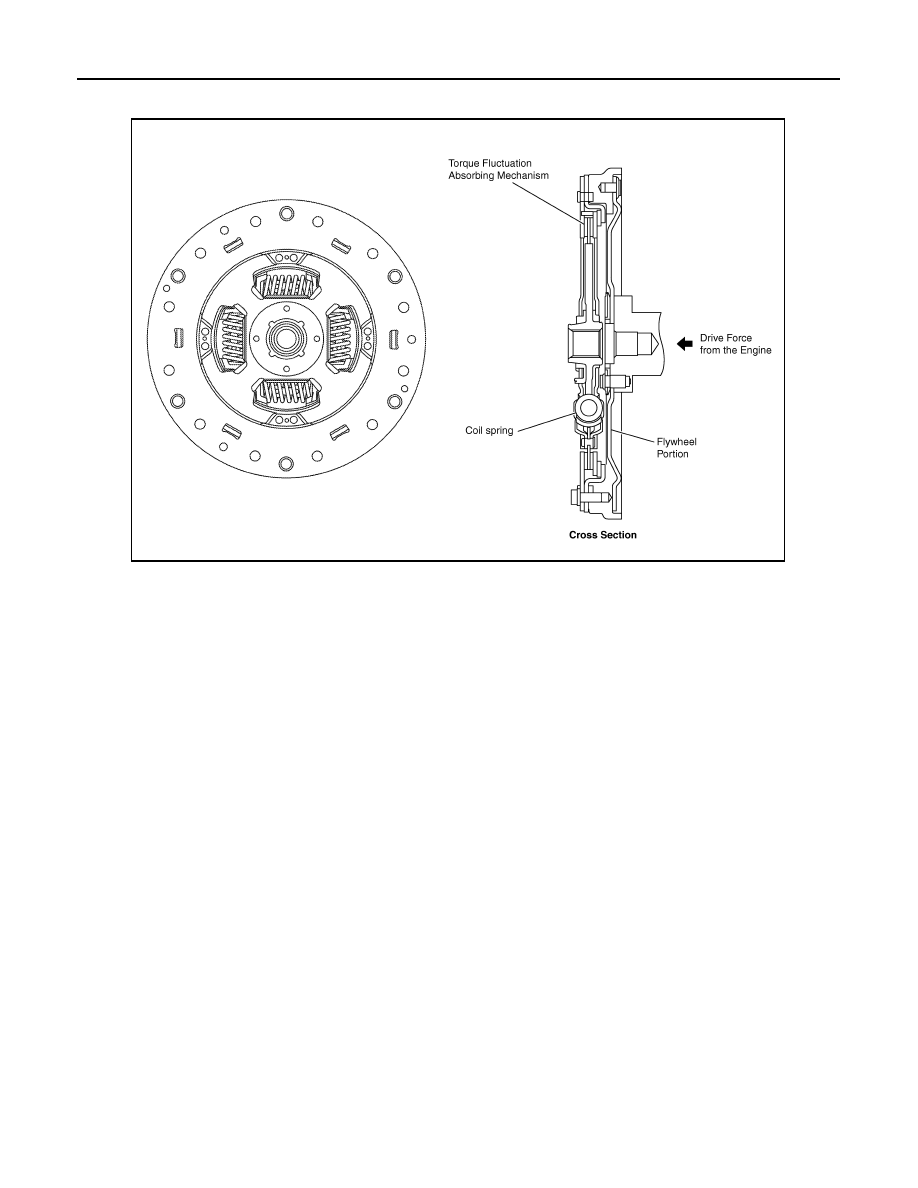

uses a dry-type, single-plate friction material is used. Through the use of the parts, a damper construction that

excels in absorbing the vibrations of the engine motive force has been achieved.

MG1 AND MG2

MG1 and MG2 are located coaxially at each end of the compound gear unit. MG1 connects to the sun gear of

the power split planetary gear, and MG2 connects to the sun gear of the motor speed reduction planetary gear.

NOTE:

Do not disassemble MG1 or MG2 because they are precision components. If a malfunction is found on either

of these components, replace MG1 or MG2 as a complete assembly.

Lubrication Mechanism

INFOID:0000000004212367

• This transaxle is lubricated by a trochoid type oil pump placed on the main shaft.

• Furthermore, it uses a final gear with an oil sling type lubrication mechanism. This construction minimizes

the drive torque of the oil pump, which reduces the drive loss.

JPDIA0091GB