Content .. 1049 1050 1051 1052 ..

Nissan Altima HL32 Hybrid. Manual - part 1051

ST-2

< SYMPTOM DIAGNOSIS >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

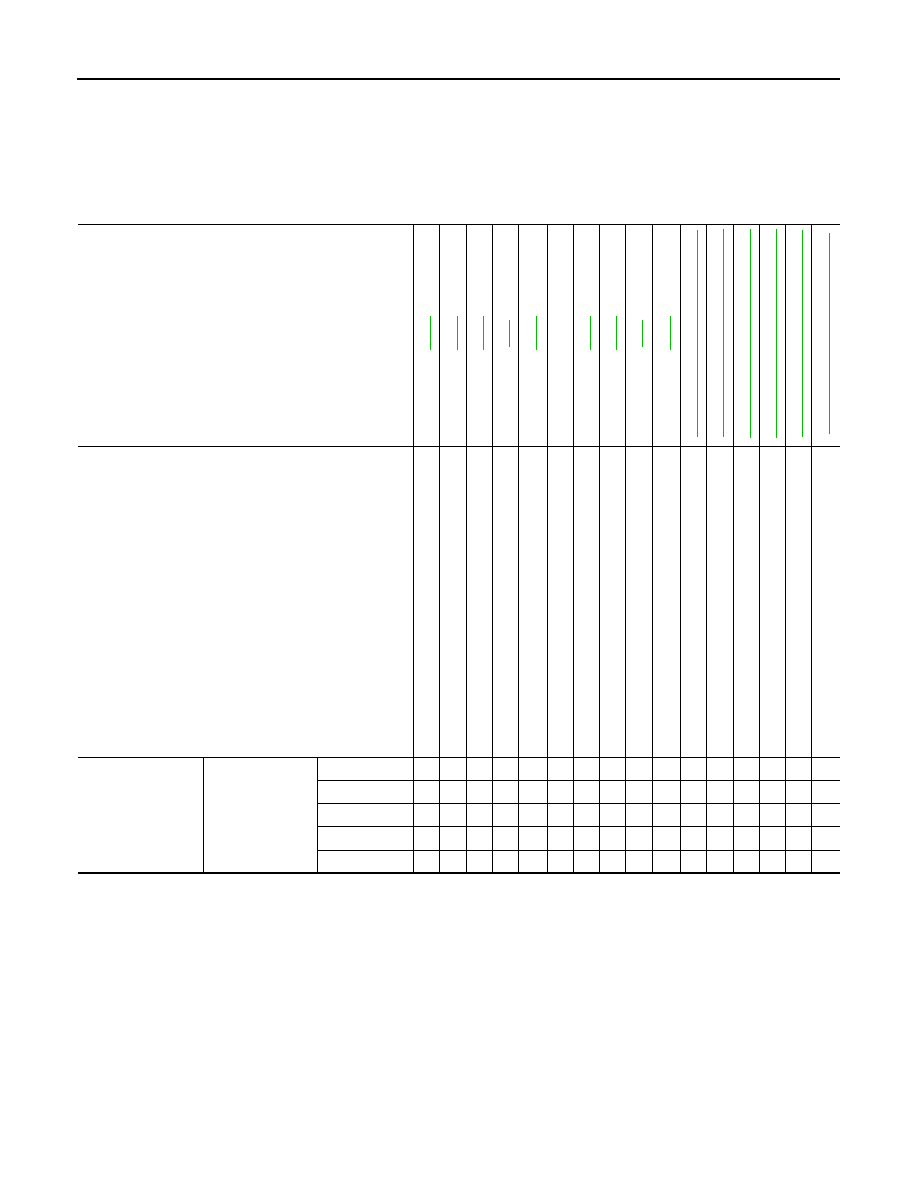

NVH Troubleshooting Chart

INFOID:0000000004212793

Use chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

×: Applicable

Reference page

—

"

"

"

"

Possible cause and SUSPECTED PARTS

O

u

ter

so

ck

et

ba

ll

joi

nt

swi

ng

ing

fo

rce

Ou

ter

so

cket

ba

ll

joi

nt

rot

ati

ng

torq

ue

O

u

ter

so

ck

et

ba

ll

joi

nt

en

d p

la

y

S

te

e

ring

whe

e

l pl

ay

S

te

e

ring

ge

ar rac

k sl

id

in

g fo

rce

Im

pro

p

er

st

ee

ring

wh

ee

l

M

ou

nt

ing

ru

bb

er d

et

erio

rat

ion

S

tee

rin

g c

o

lum

n

de

form

at

ion

o

r da

ma

ge

Im

p

rop

er i

ns

tal

la

tio

n o

r lo

os

en

es

s of

st

ee

ring

c

olu

m

n

S

te

e

ring

li

nk

ag

e l

o

os

en

es

s

W

H

EEL

H

U

B

AND AXLE

S

U

S

PENSION

TI

RE

S

ROAD W

H

EEL

DRIV

E

SHAFT

BR

AK

E

S

Symptom

Steering

Noise

×

×

×

×

×

×

×

×

×

×

×

Shake

×

×

×

×

×

×

×

Vibration

×

×

×

×

×

×

×

Shimmy

×

×

×

×

×

×

×

Shudder

×

×

×

×

×

×