Nissan Frontier. Manual - part 987

ENGINE OIL

LU-9

< PERIODIC MAINTENANCE >

[QR25DE]

C

D

E

F

G

H

I

J

K

L

M

A

LU

N

P

O

PERIODIC MAINTENANCE

ENGINE OIL

Inspection

INFOID:0000000009479889

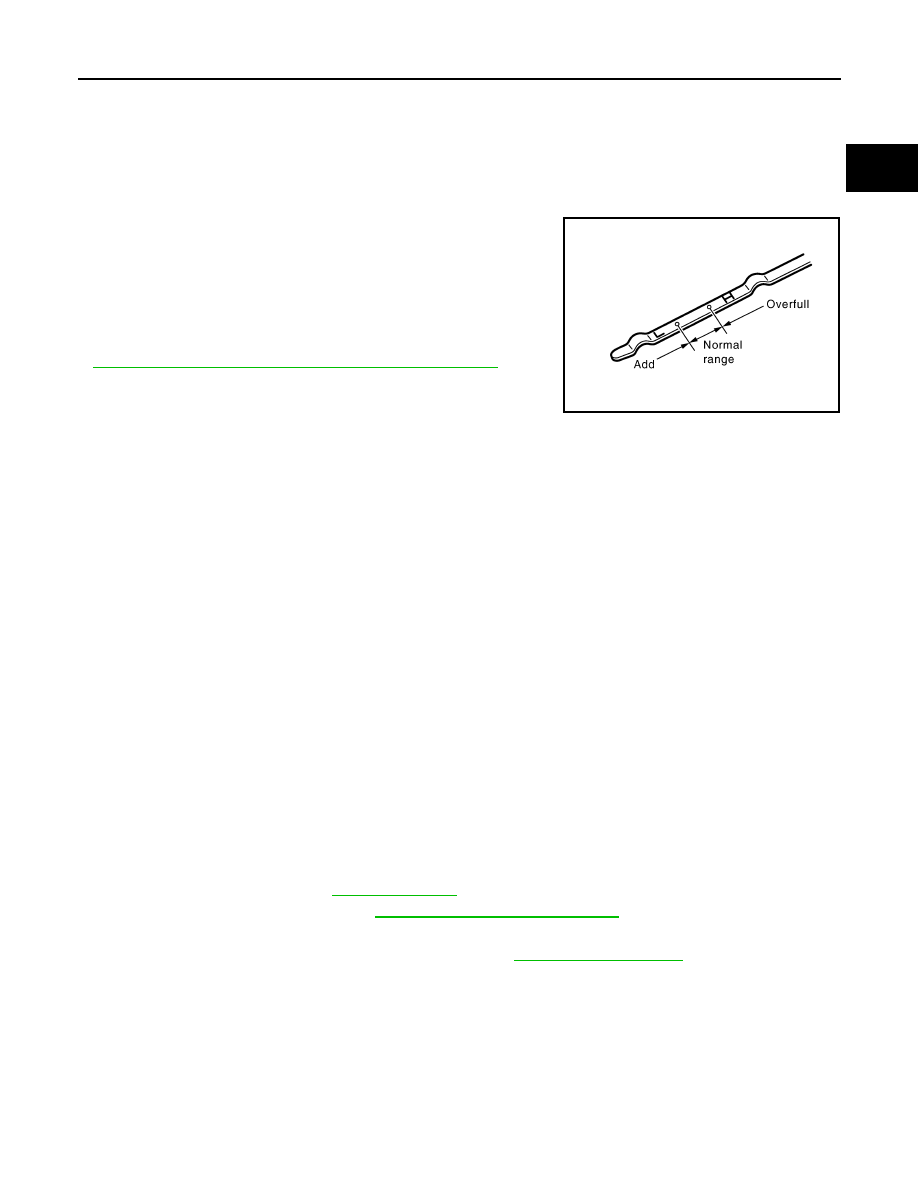

OIL LEVEL

• Before starting the engine make sure the vehicle is parked on a flat

and level surface, then check the oil level. If the engine is already

running, turn it off and allow 10 minutes before checking.

• Pull out oil level gauge and wipe clean.

• Insert oil level gauge.

• Check that the oil level is within the low (L) and high (H) range as

indicated on the dipstick.

• If the engine oil level is out of range, add oil as necessary. Refer to

MA-16, "FOR USA AND CANADA : Fluids and Lubricants"

.

CAUTION:

Do not overfill the engine with oil.

NOTE:

It is normal to add some oil between oil maintenance intervals or during the break-in period, depending on

the severity of the operating conditions.

OIL APPEARANCE

• Check the engine oil for a white milky appearance or excessive contamination.

• If the engine oil is milky, it is highly probable that it is contaminated with engine coolant. Repair or replace

damaged parts.

OIL LEAKAGE

Check for engine oil leakage around the following area.

• Oil pan

• Oil pan drain plug

• Oil pressure switch

• Oil filter

• Oil cooler

• Intake valve timing control cover and intake valve timing control solenoid valve

• Front cover

• Mating surface between cylinder block and lower cylinder block

• Mating surface between cylinder block and cylinder head

• Mating surface between cylinder head and rocker cover

• Crankshaft oil seals (front and rear)

OIL PRESSURE CHECK

WARNING:

• Be careful not to burn yourself, as the engine and engine oil may be hot.

• Put the A/T shift selector in the Park (P) position (A/T models) or Neutral position (M/T models), and

apply parking brake securely.

1. Check engine oil level. Refer to

.

2. Remove engine under cover. Refer to

EXT-15, "Removal and Installation"

.

3. Disconnect the oil pressure switch harness connector.

4. Remove oil pressure switch using a suitable tool. Refer to

.

CAUTION:

Do not drop or shock oil pressure switch.

PBIC2823E