Nissan Frontier. Manual - part 842

GI-36

< PRECAUTION >

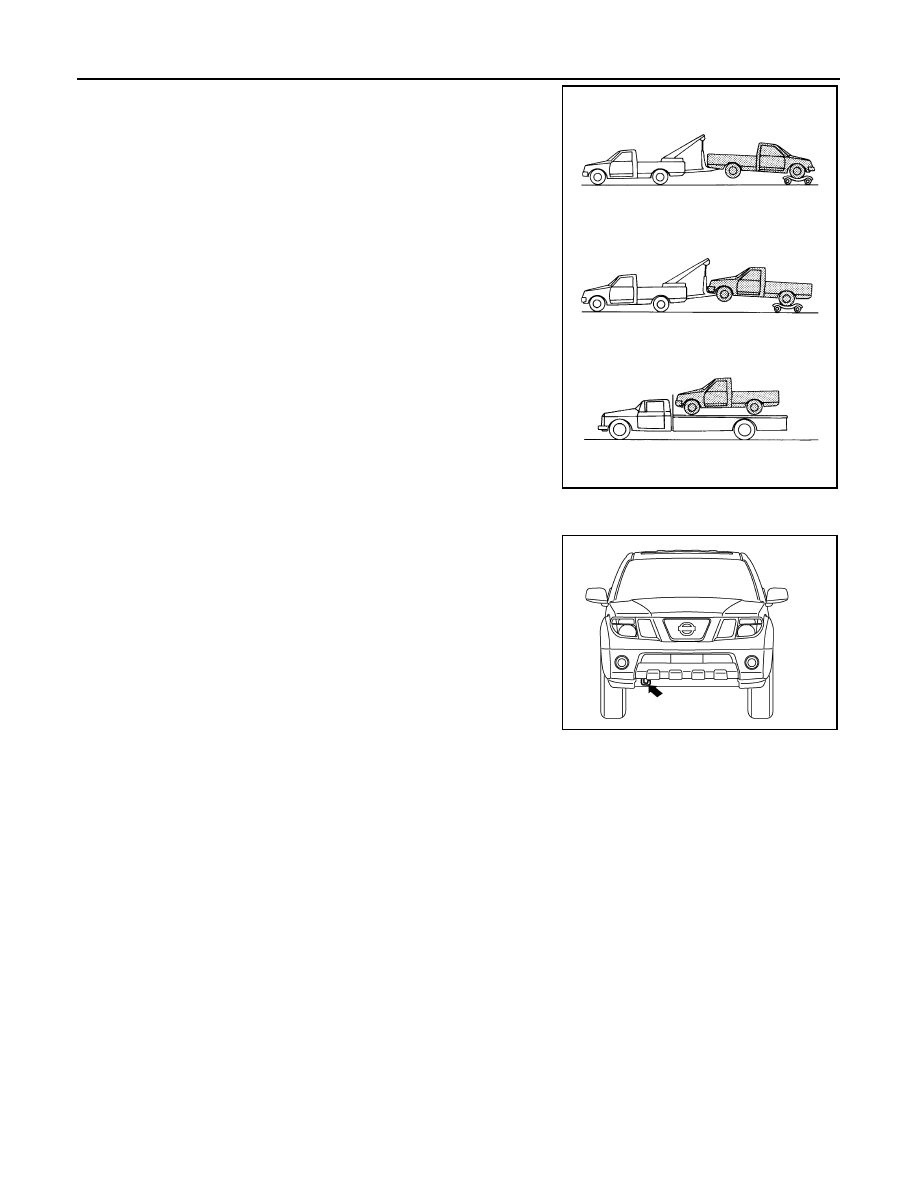

TOW TRUCK TOWING

NISSAN recommends that towing dollies be used when towing 4WD

equipped vehicles or place the vehicle on a flat bed truck.

CAUTION:

• Never tow 4WD models with any of the wheels on the ground

as this may cause serious and expensive damage to the

transfer case and transmission.

Towing Point

CAUTION:

Never tow the vehicle using only the towing points. To avoid

damaging the vehicle body, use proper towing equipment when

towing.

Vehicle Recovery (Freeing a stuck vehicle)

INFOID:0000000009480229

• Tow chains or cables must be attached only to the main structural members of the vehicle.

• Pulling devices should be routed so they do not touch any part of the suspension, steering, brake or

cooling systems

• Always pull the cable straight out from the front or rear of the vehicle. Never pull the vehicle at a

sideways angle.

• Pulling devices such as ropes or canvas straps are not recommended for use for vehicle towing or

recovery.

SGI973

LAIA0053E