Nissan Frontier. Manual - part 708

CAMSHAFT VALVE CLEARANCE

EM-21

< PERIODIC MAINTENANCE >

[QR25DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

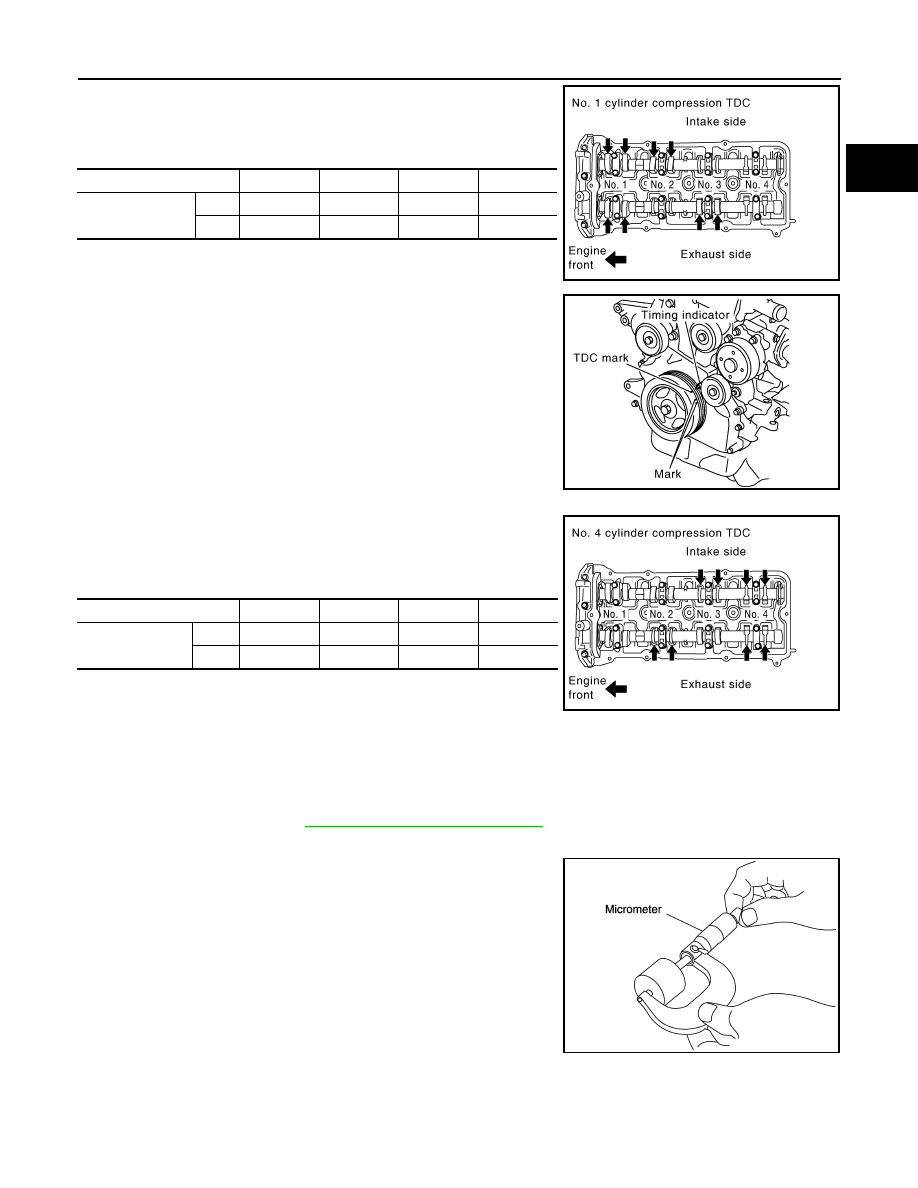

• Measure the valve clearances at locations marked “

×” as

shown in the table below (locations indicated with black arrow

shown) with feeler gauge.

• No. 1 cylinder compression TDC

c. Rotate crankshaft one revolution (360

°) and align TDC mark to

timing indicator on front cover.

• Measure the valve clearance at locations marked “

×” as shown

in the table below (locations indicated with black arrow shown)

with feeler gauge.

• No. 4 cylinder compression TDC

5. If out of standard, perform adjustment.

ADJUSTMENT

• Perform adjustment depending on selected head thickness of valve lifter.

1. Measure the valve clearance.

2. Remove camshaft. Refer to

EM-54, "Removal and Installation"

3. Remove valve lifters at the locations that are out of the standard.

4. Measure the center thickness of the removed valve lifters with a

micrometer.

5. Use the equation below to calculate valve lifter thickness for replacement.

Measuring position

No. 1 CYL.

No. 2 CYL.

No. 3 CYL.

No. 4 CYL.

No. 1 cylinder at

compression TDC

INT

×

×

EXH

×

×

PBIC3017E

PBIC3015E

Measuring position

No. 1 CYL.

No. 2 CYL.

No. 3 CYL.

No. 4 CYL.

No. 4 cylinder at

compression TDC

INT

×

×

EXH

×

×

PBIC3026E

KBIA0057E