Nissan Frontier. Manual - part 634

P0075, P0081 IVT CONTROL SOLENOID VALVE

EC-1107

< DTC/CIRCUIT DIAGNOSIS >

[VQ40DE FOR MEXICO]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

P0075, P0081 IVT CONTROL SOLENOID VALVE

Component Description

INFOID:0000000009481751

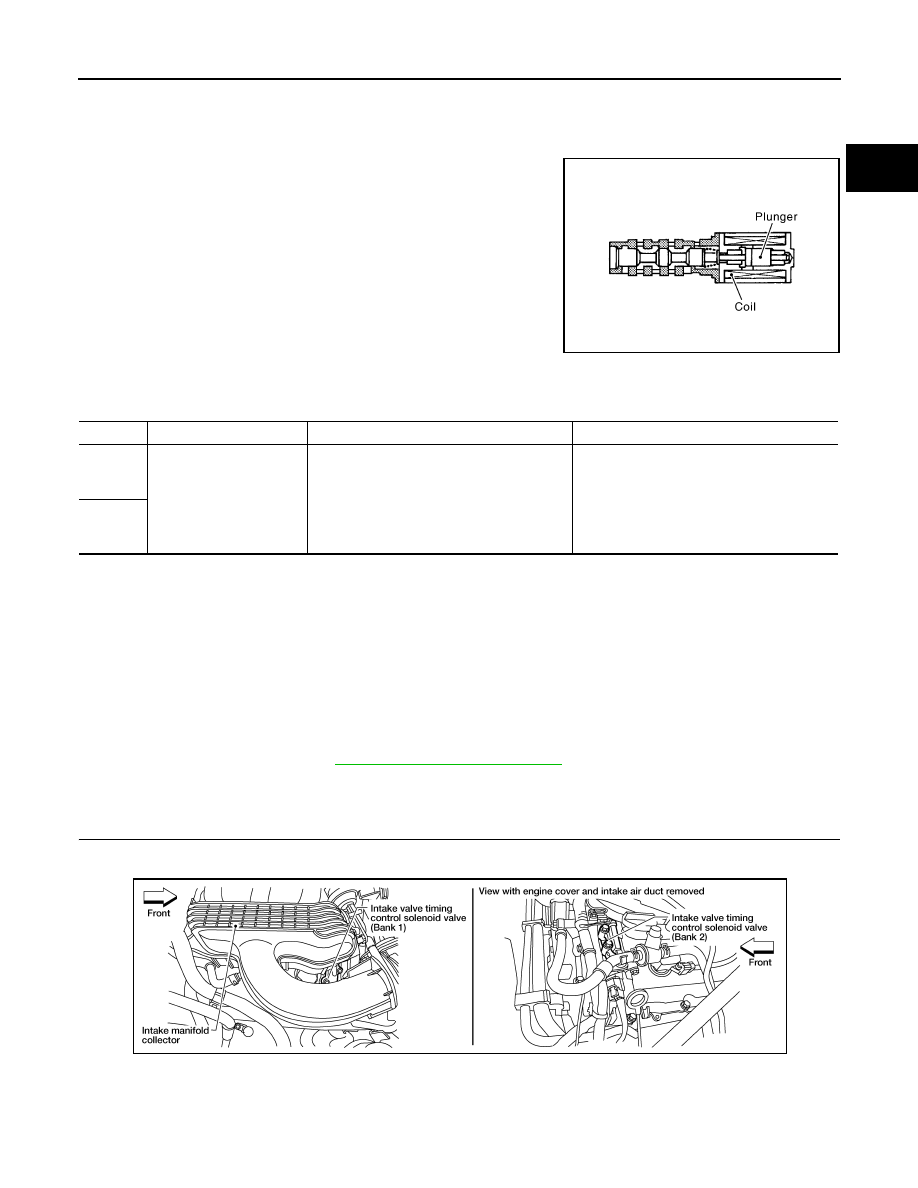

Intake valve timing control solenoid valve is activated by ON/OFF

pulse duty (ratio) signals from the ECM.

The intake valve timing control solenoid valve changes the oil

amount and direction of flow through intake valve timing control unit

or stops oil flow.

The longer pulse width advances valve angle.

The shorter pulse width retards valve angle.

When ON and OFF pulse widths become equal, the solenoid valve

stops oil pressure flow to fix the intake valve angle at the control

position.

On Board Diagnosis Logic

INFOID:0000000009481752

DTC Confirmation Procedure

INFOID:0000000009481753

1. If DTC Confirmation Procedure has been previously conducted, always perform the following before con-

ducting the next step.

a. Turn ignition switch OFF and wait at least 10 seconds.

b. Turn ignition switch ON.

c. Turn ignition switch OFF and wait at least 10 seconds.

2. Start engine and let it idle for 5 seconds.

3. Check 1st trip DTC.

4. If 1st trip DTC is detected, go to

EC-1107, "Diagnosis Procedure"

Diagnosis Procedure

INFOID:0000000009481754

1.

CHECK INTAKE VALVE TIMING CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect intake valve timing control solenoid valve harness connector.

3. Turn ignition switch ON.

PBIB1842E

DTC No.

Trouble diagnosis name

DTC detecting condition

Possible cause

P0075

0075

(Bank 1)

Intake valve timing control

solenoid valve circuit

An improper voltage is sent to the ECM

through intake valve timing control solenoid

valve.

• Harness or connectors

(Intake valve timing control solenoid valve

circuit is open or shorted.)

• Intake valve timing control solenoid valve

P0081

0081

(Bank 2)

BBIA0553E