Nissan Frontier. Manual - part 534

P0172, P0175 FUEL INJECTION SYSTEM FUNCTION

EC-707

< DTC/CIRCUIT DIAGNOSIS >

[VQ40DE FOR USA AND CANADA]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

7. If it is difficult to start engine at step 6, the fuel injection system has a malfunction, too.

8. Crank engine while depressing accelerator pedal.

If engine starts, go to

. If engine does not start, remove spark plugs and

check for fouling, etc.

WITH GST

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

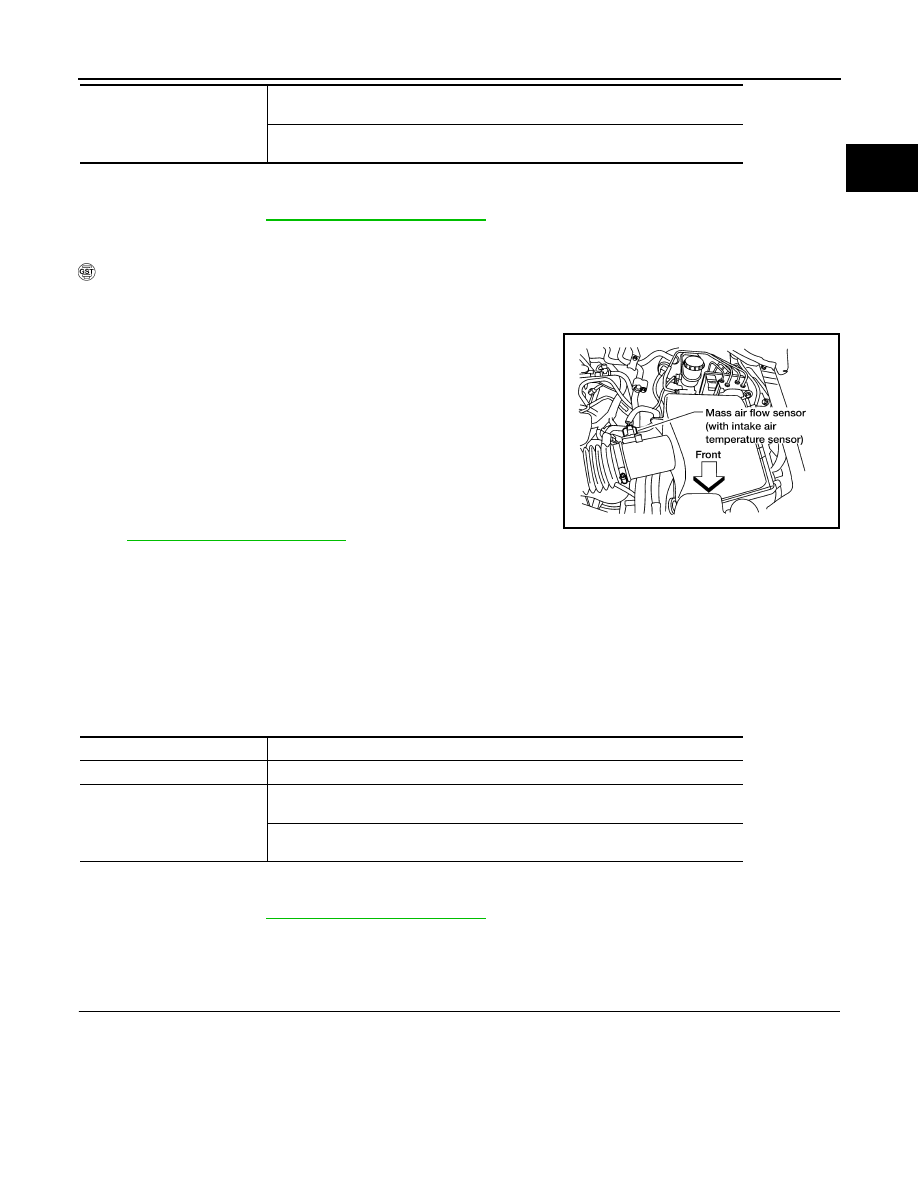

3. Disconnect mass air flow sensor harness connector. Then

restart and run engine for at least 5 seconds at idle speed.

4. Stop engine and reconnect mass air flow sensor harness con-

nector.

5. Select Service $03 with GST. Make sure DTC P0102 is

detected.

6. Select Service $04 with GST and erase the DTC P0102.

7. Start engine again and let it idle for at least 10 minutes.

8. Select Service $07 with GST. The 1st trip DTC P0172 or P0175

should be detected at this stage, if a malfunction exists. If so, go

.

NOTE:

If 1st trip DTC is not detected during above procedure, performing the following procedure is advised.

a. Turn ignition switch OFF and wait at least 10 seconds.

b. Start engine and drive the vehicle under the similar conditions to (1st trip) Freeze Frame Data for 10 min-

utes. Refer to the table below.

Hold the accelerator pedal as steady as possible.

The similar conditions to (1st trip) Freeze Frame Data means the vehicle operation that the following con-

ditions should be satisfied at the same time.

9. If it is difficult to start engine at step 7, the fuel injection system has a malfunction.

10. Crank engine while depressing accelerator pedal.

If engine starts, go to

. If engine does not start, remove spark plugs and

check for fouling, etc.

Diagnosis Procedure

INFOID:0000000009481362

1.

CHECK EXHAUST GAS LEAK

1. Start engine and run it at idle.

Engine coolant temperature (T)

condition

When the freeze frame data shows lower than 70

°C (158 °F),

T should be lower than 70

°C (158 °F).

When the freeze frame data shows higher than or equal to 70

°C (158 °F),

T should be higher than or equal to 70

°C (158 °F).

BBIA0368E

Engine speed

Engine speed in the freeze frame data

± 400 rpm

Vehicle speed

Vehicle speed in the freeze frame data

± 10 km/h (6 MPH)

Engine coolant temperature (T)

condition

When the freeze frame data shows lower than 70

°C (158 °F),

T should be lower than 70

°C (158 °F).

When the freeze frame data shows higher than or equal to 70

°C (158 °F),

T should be higher than or equal to 70

°C (158 °F).