Nissan Frontier. Manual - part 449

P1217 ENGINE OVER TEMPERATURE

EC-367

< DTC/CIRCUIT DIAGNOSIS >

[QR25DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

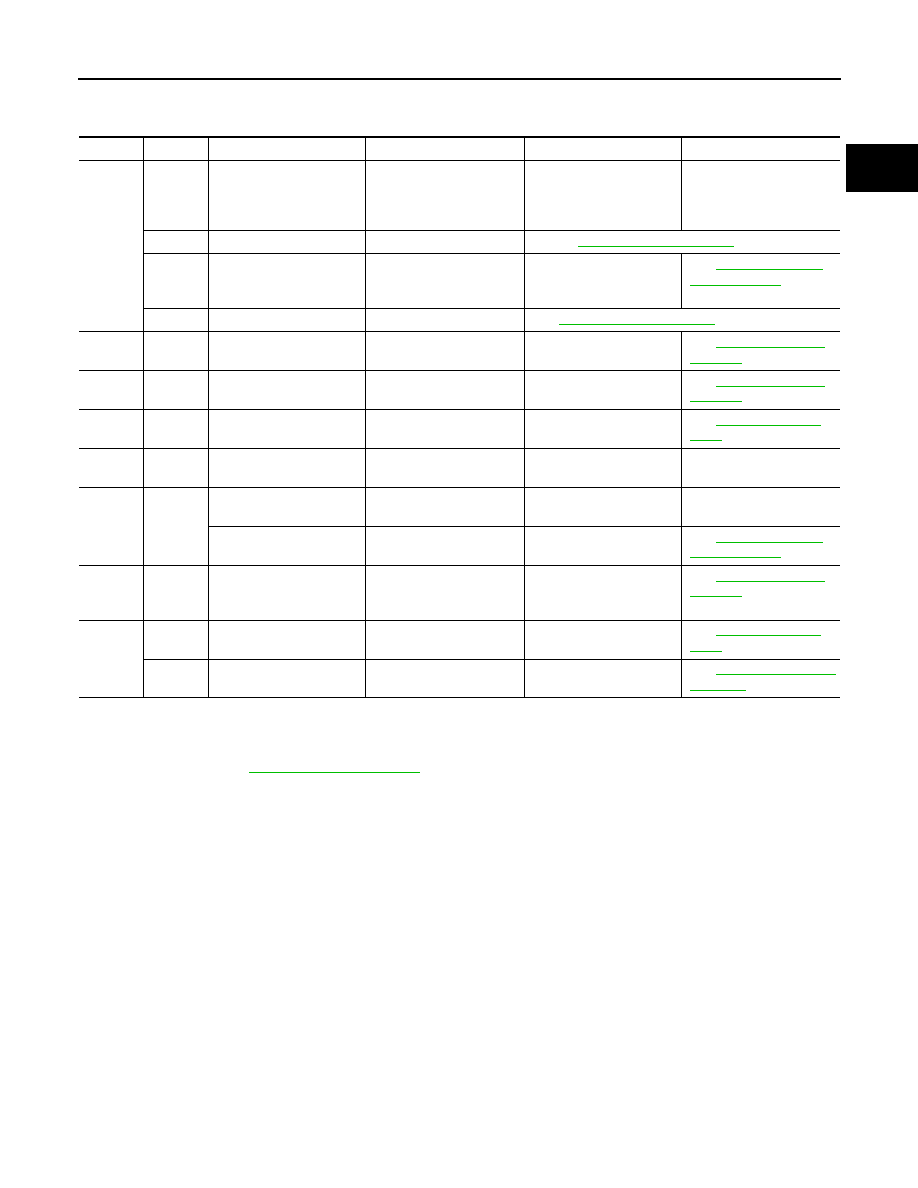

Main 12 Causes of Overheating

INFOID:0000000009481049

*1: Engine running at 3,000 rpm for 10 minutes.

*2: Drive at 90 km/h (55 MPH) for 30 minutes and then let idle for 10 minutes.

*3: After 60 minutes of cool down time.

For more information, refer to

.

Engine

Step

Inspection item

Equipment

Standard

Reference page

OFF

1

• Blocked radiator

• Blocked condenser

• Blocked radiator grille

• Blocked bumper

• Visual

No blocking

—

2

• Coolant mixture

• Coolant tester

Refer to

3

• Coolant level

• Visual

Coolant up to MAX level

in reservoir tank and radi-

ator filler neck

See

.

4

• Radiator cap

• Pressure tester

See

ON*

1

5

• Coolant leaks

• Visual

No leaks

See

ON*

1

6

• Thermostat

• Touch the upper and

lower radiator hoses

Both hoses should be hot See

ON*

1

7

• Cooling fan

• Visual

Operating

See

OFF

8

• Combustion gas leak

• Color checker chemical

tester 4 Gas analyzer

Negative

—

ON*

2

9

• Coolant temperature

gauge

• Visual

Gauge less than 3/4 when

driving

—

• Coolant overflow to res-

ervoir tank

• Visual

No overflow during driving

and idling

See

.

OFF*

3

10

• Coolant return from

reservoir tank to radia-

tor

• Visual

Should be initial level in

reservoir tank

See

OFF

11

• Cylinder head

• Straight gauge feeler

gauge

0.1 mm (0.004 in) Maxi-

mum distortion (warping)

See

12

• Cylinder block and pis-

tons

• Visual

No scuffing on cylinder

walls or piston

See