Nissan Frontier. Manual - part 420

P0300, P0301, P0302, P0303, P0304 MISFIRE

EC-251

< DTC/CIRCUIT DIAGNOSIS >

[QR25DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

When disconnecting each fuel injector harness connector one at a

time, is there any cylinder which does not produce a momentary

engine speed drop?

Yes or No

Yes

>> GO TO 4.

No

>> GO TO 9.

4.

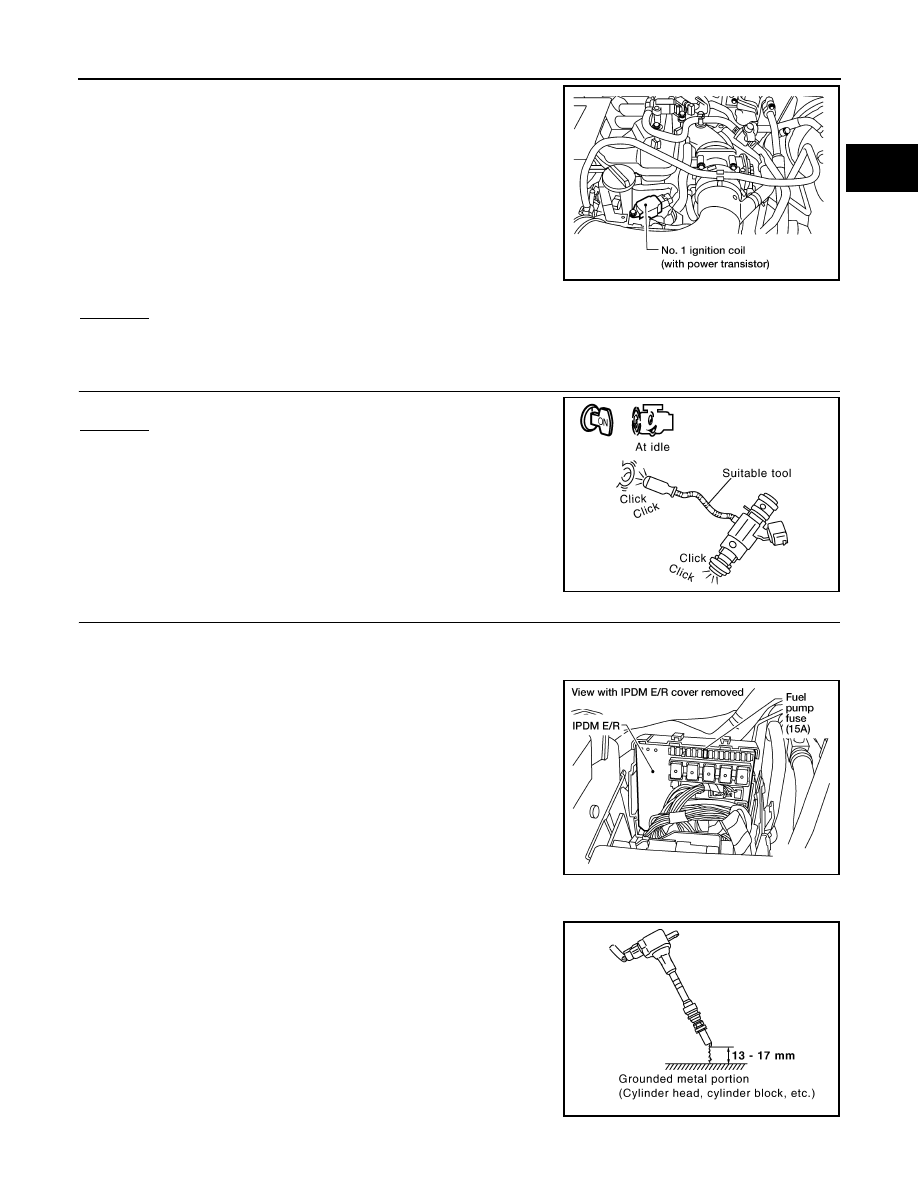

CHECK FUNCTION OF FUEL INJECTOR

Does each fuel injector make an operating sound at idle?

Yes or No

Yes

>> GO TO 5.

No

>> Check fuel injector(s) and circuit(s).

5.

CHECK FUNCTION OF IGNITION COIL-I

CAUTION:

Never the following procedure in a place with no combusyible objects and good ventilation.

1. Turn ignition switch OFF.

2. Remove fuel pump fuse in IPDM E/R to release fuel pressure.

NOTE:

Do not use CONSULT to release fuel pressure, or fuel pressure

applies again during the following procedure.

3. Start engine.

4. After engine stalls, crank it two or three times to release all fuel

pressure.

5. Turn ignition switch OFF.

6. Remove all ignition coil harness connectors to avoid the electri-

cal discharge from the ignition coils.

7. Remove ignition coil and spark plug of the cylinder to be

checked.

8. Crank engine for 5 seconds or more to remove combustion gas in the cylinder.

9. Connect spark plug and harness connector to ignition coil.

10. Fix ignition coil using a rope etc. with gap of 13 - 17 mm

between the edge of the spark plug and grounded metal portion

as shown in the figure.

11. Crank engine for about three seconds, and check whether spark

is generated between the spark plug and the grounded metal

portion.

CAUTION:

BBIA0604E

PBIB1986E

Spark should be generated.

BBIA0534E

PBIB2325E