Content .. 1090 1091 1092 1093 ..

Nissan Frontier. Manual - part 1092

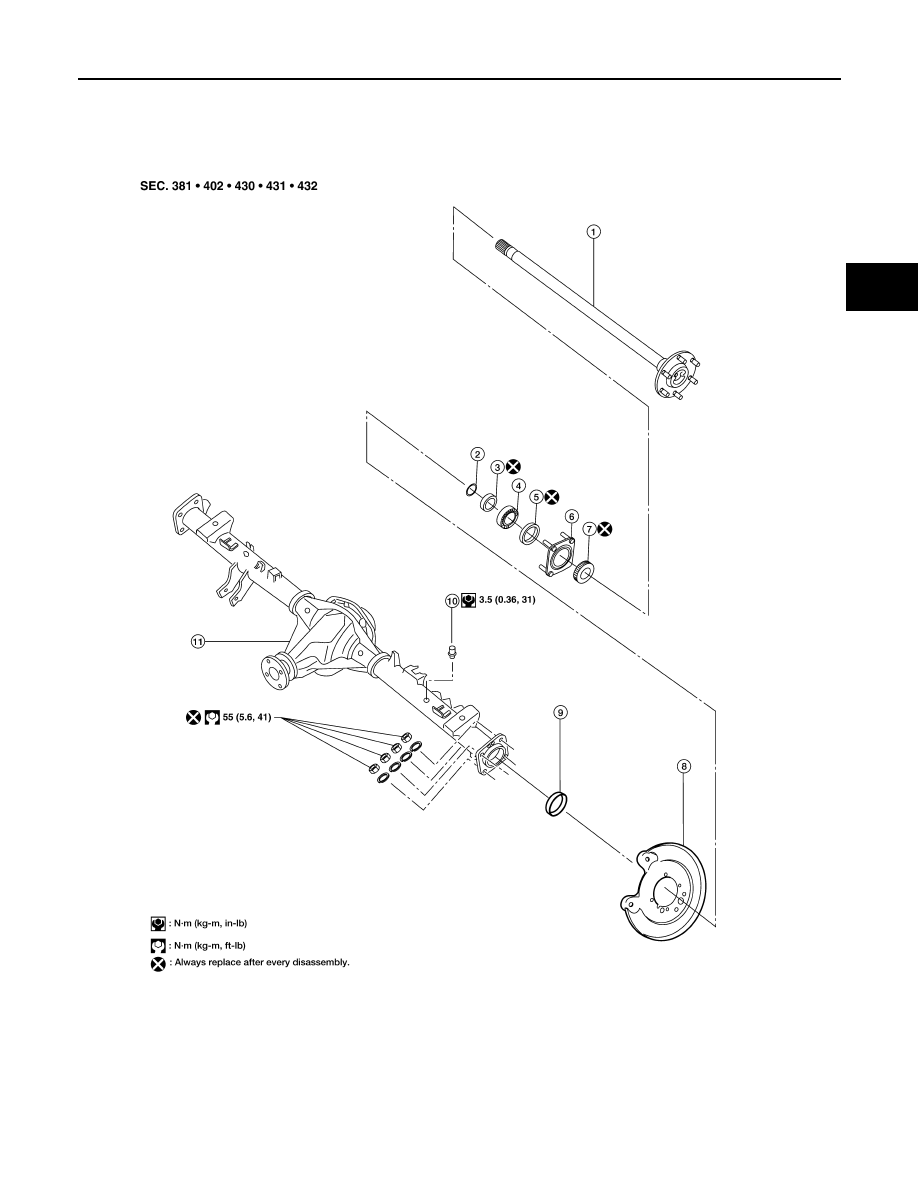

AXLE SHAFT

RAX-19

< SERVICE INFORMATION >

[M226]

C

E

F

G

H

I

J

K

L

M

A

B

RAX

N

O

P

AXLE SHAFT

Removal and Installation

INFOID:0000000009478721

CAUTION:

1.

Axle shaft

2.

Snap ring

3.

Bearing ring retainer

4.

Axle shaft bearing

5.

Axle oil seal

6.

Axle shaft bearing cage

7.

Wheel sensor rotor

8.

Back plate and torque member

9.

Axle shaft bearing cup

10. Breather

11. Rear final drive

WDIA0181E