Nissan Sentra. Manual - part 899

TM-232

< DTC/CIRCUIT DIAGNOSIS >

[CVT: RE0F11A]

P285A CLUTCH B PRESSURE

P285A CLUTCH B PRESSURE

DTC Logic

INFOID:0000000009759480

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

• Be sure to perform “

” and then perform “DTC CONFIRMATION PRO-

CEDURE”.

• Never perform “DTC CONFIRMATION PROCEDURE” before the repairs. Doing so may result in a sec-

ondary malfunction.

• Be careful of the driving speed.

1.

PREPARATION BEFORE WORK

If another “DTC CONFIRMATION PROCEDURE” occurs just before, turn ignition switch OFF and wait for at

least 10 seconds, then perform the next test.

>> GO TO 2.

2.

CHECK DTC DETECTION

1. Start the engine.

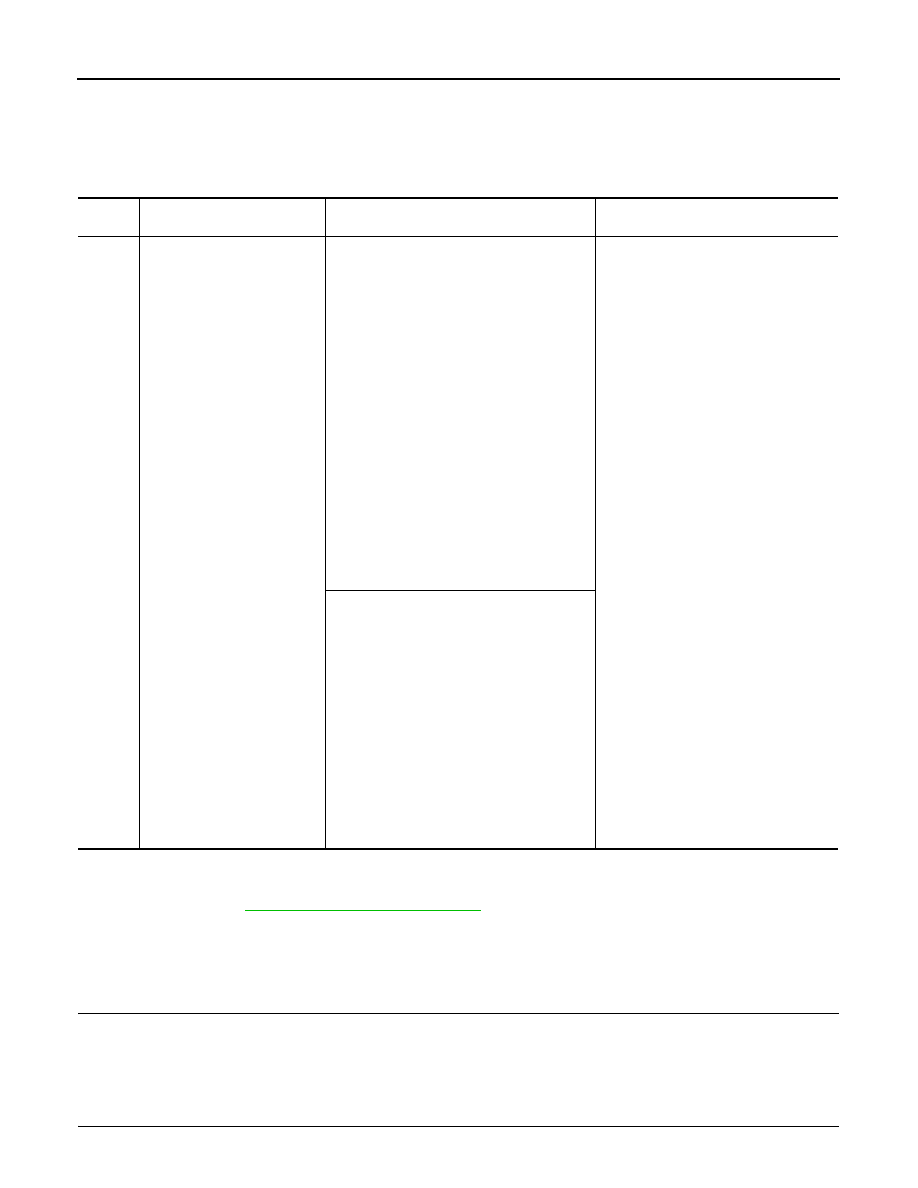

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

Possible causes

P285A

CLUTCH B PRESSURE

(Clutch B Pressure Disengage-

ment Performance)

The detection conditions continuously for 200

msec or more under the following diagnosis

conditions:

• Diagnosis conditions

- Selector lever: Other than “P”, “R” and “N”

positions

- Vehicle speed: 10 km/h (6 MPH) or more

- Engine speed: More than 550 rpm

- Output speed: More than 300 rpm

- Secondary pulley speed: More than 300

rpm

- A lapse of 500 msec or more after the stop

lamp switch is turned from ON to OFF.

- Command for the 1GR of auxiliary gearbox

is in progress.

- Auxiliary gearbox shifting is not in progress.

- TCM power supply voltage: More than 11 V

• Detection conditions

- Acceleration/deceleration: Less than

−0.05

G

- Actual auxiliary gearbox gear ratio

− Auxilia-

ry gearbox 1GR ratio

≥ 50%

• High clutch & reverse brake solenoid

valve

• Control valve assembly

The auxiliary gearbox gear ratio is

±10% or

less for the auxiliary gearbox 2GR ratio contin-

uously for 500 msec or more under the follow-

ing diagnosis conditions:

• Diagnosis conditions

- Selector lever: Other than “P”, “R” and “N”

positions

- Accelerator pedal position: 0.7/8 or more

- Engine speed: More than 550 rpm

- Secondary pulley speed: More than 300

rpm

- Output speed: More than 300 rpm

- Command for the 1GR of auxiliary gearbox

is in progress.

- Auxiliary gearbox shifting is not in progress.

- TCM power supply voltage: More than 11 V