Nissan Sentra. Manual - part 878

TM-148

< BASIC INSPECTION >

[CVT: RE0F11A]

STALL TEST

STALL TEST

Work Procedure

INFOID:0000000009759378

INSPECTION

1. Check the engine oil level. Replenish if necessary. Refer to

2. Check for leak of the CVT fluid. Refer to

.

3. Drive for about 10 minutes to warm up the vehicle so that the CVT fluid temperature is 50 to 80

°C (122 to

176

°F).

4. Be sure to apply the parking brake and block the tires.

5. Start the engine, depress the brake pedal and put the selector lever to the D position.

6. While depressing the brake pedal, depress the accelerator pedal gradually.

7. Read the stall speed quickly. Then, release your foot from the accelerator pedal quickly.

CAUTION:

Never depress the accelerator pedal for 5 seconds or more during the test.

8. Place the selector lever in the N position.

9. Cool the CVT fluid.

CAUTION:

Run the engine with the idle speed for at least 1 minute.

10. Put the selector lever to the R position and perform Step 6 to Step 9 again.

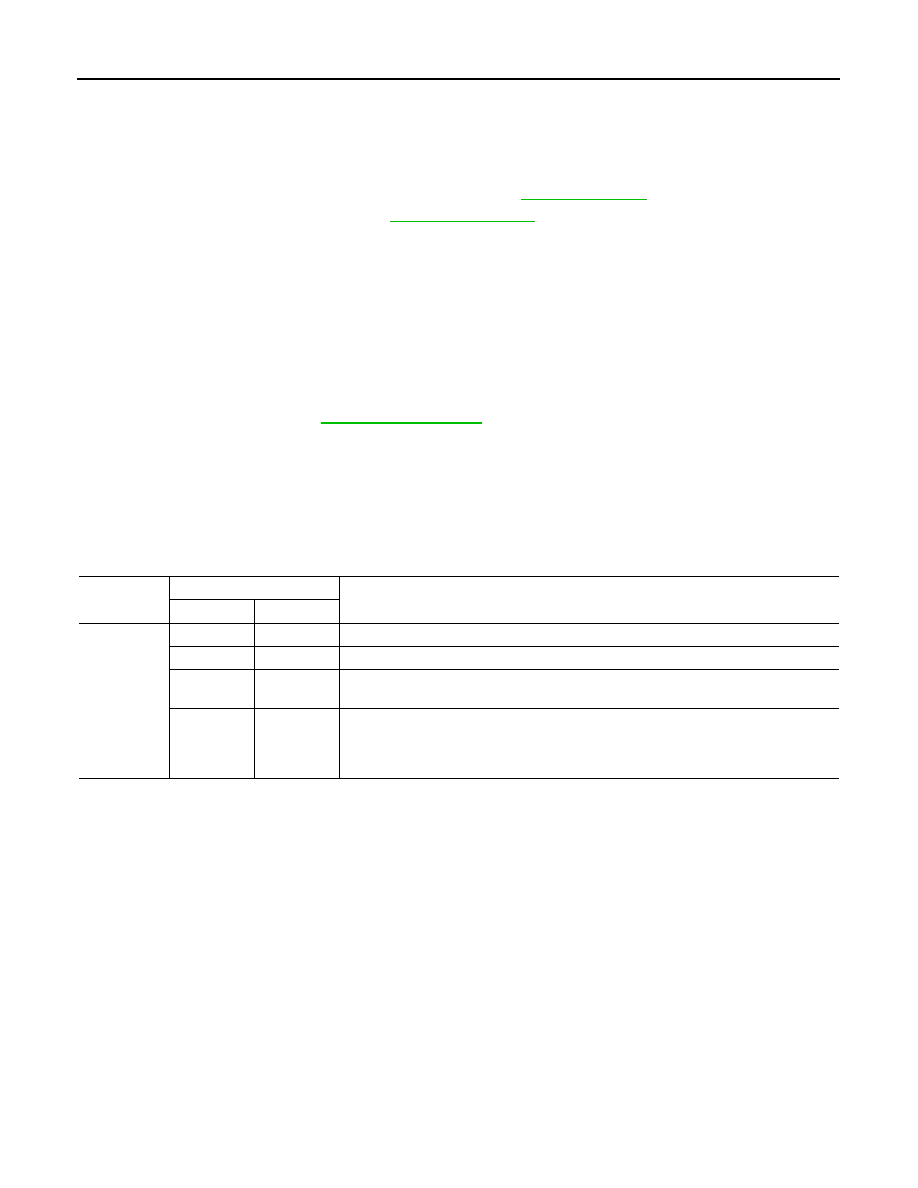

NARROWING-DOWN MALFUNCTIONING PARTS

O: Within the stall speed standard value

H: Stall speed is higher than the standard value.

L: Stall speed is lower than the standard value.

Stall speed

: Refer to

.

Selector lever position

Possible cause

D

R

Stall speed

H

O

• Low brake

O

H

• Reverse brake

L

L

• Engine

• Torque converter one way clutch

H

H

• Line pressure is low.

• Primary pulley

• Secondary pulley

• Steel belt