Nissan Sentra. Manual - part 840

STR-28

< DTC/CIRCUIT DIAGNOSIS >

S CONNECTOR CIRCUIT

S CONNECTOR CIRCUIT

Description

INFOID:0000000009759165

The starter motor magnetic switch is supplied with power when the ignition switch is turned to the START posi-

tion while the selector lever is in the P (Park) or N (Neutral) position (CVT Models) or the clutch pedal is

depressed (M/T Models).

Diagnosis Procedure

INFOID:0000000009759166

Regarding Wiring Diagram information, refer to

(with Intellignet Key system) or

(without Intelligent Key system).

CAUTION:

Perform diagnosis under the condition that engine cannot start by the following procedure.

1. Remove fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is released.

1.

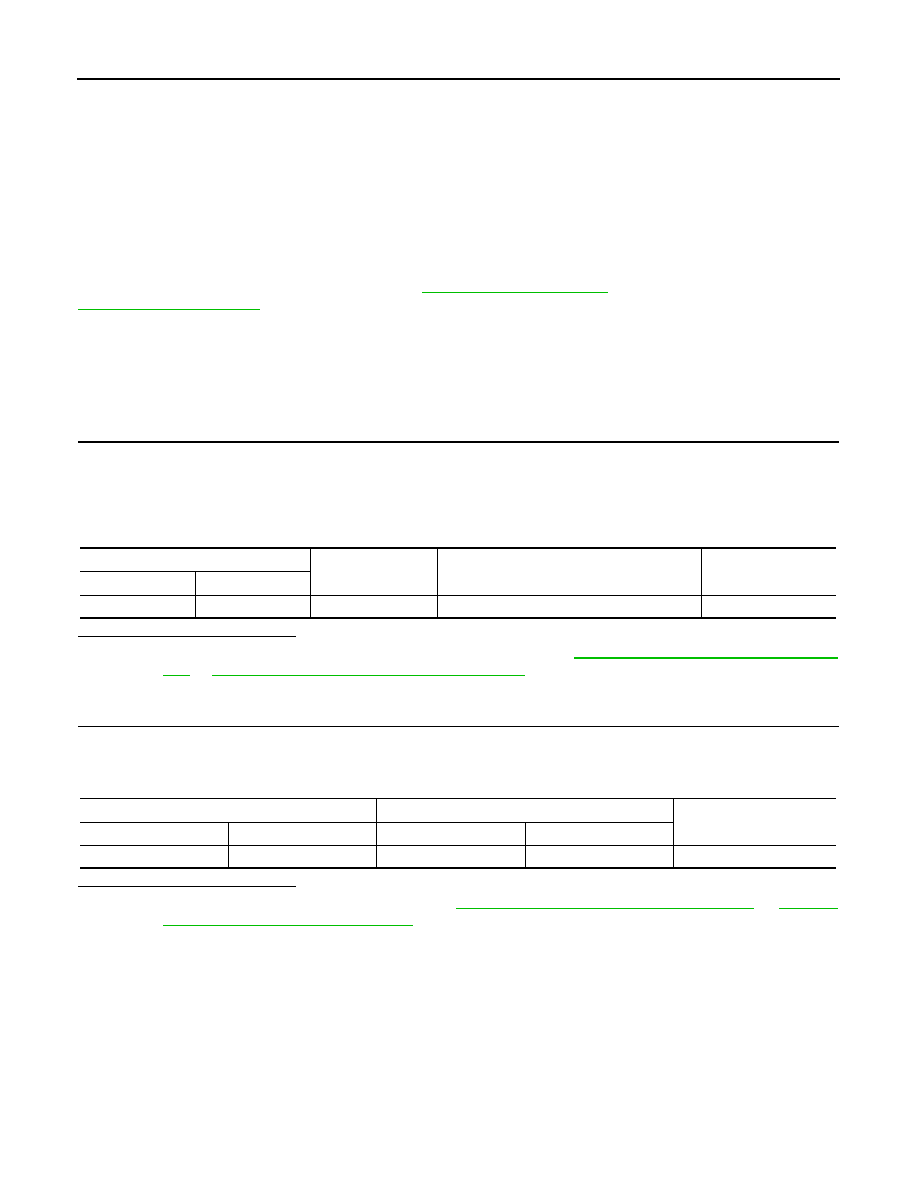

CHECK “S” CONNECTOR CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect starter motor connector.

3. Shift selector lever to “P” (Park) or “N” (Neutral) position (CVT Models) or the clutch pedal is depressed

(M/T Models).

4. Check voltage between starter motor harness connector F28 and ground.

Is the inspection result normal?

YES

>> “S” circuit is OK. Further inspection is necessary. Refer to

STR-20, "Work Flow (With GR8-1200

STR-24, "Work Flow (Without GR8-1200 NI)"

.

NO

>> GO TO 2.

2.

CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

1. Disconnect IPDM E/R connector.

2. Check continuity between starter motor harness connector F28 and the IPDM E/R harness connector

E44.

Is the inspection result normal?

YES

>> Further inspection is necessary. Refer to

STR-20, "Work Flow (With GR8-1200 NI)"

"Work Flow (Without GR8-1200 NI)"

.

NO

>> Repair or replace the harness or connectors.

(+)

(-)

Condition

Voltage

(Approx.)

Connector Terminal

F28

ST

Ground

When the ignition switch is in START position

Battery voltage

Starter motor harness connector

IPDM E/R harness connector

Continuity

Connector

Terminal

Connector

Terminal

F28

ST

E44

19

Yes