Nissan Sentra. Manual - part 561

HAC-92

< DTC/CIRCUIT DIAGNOSIS >

[AUTOMATIC AIR CONDITIONER]

BLOWER MOTOR

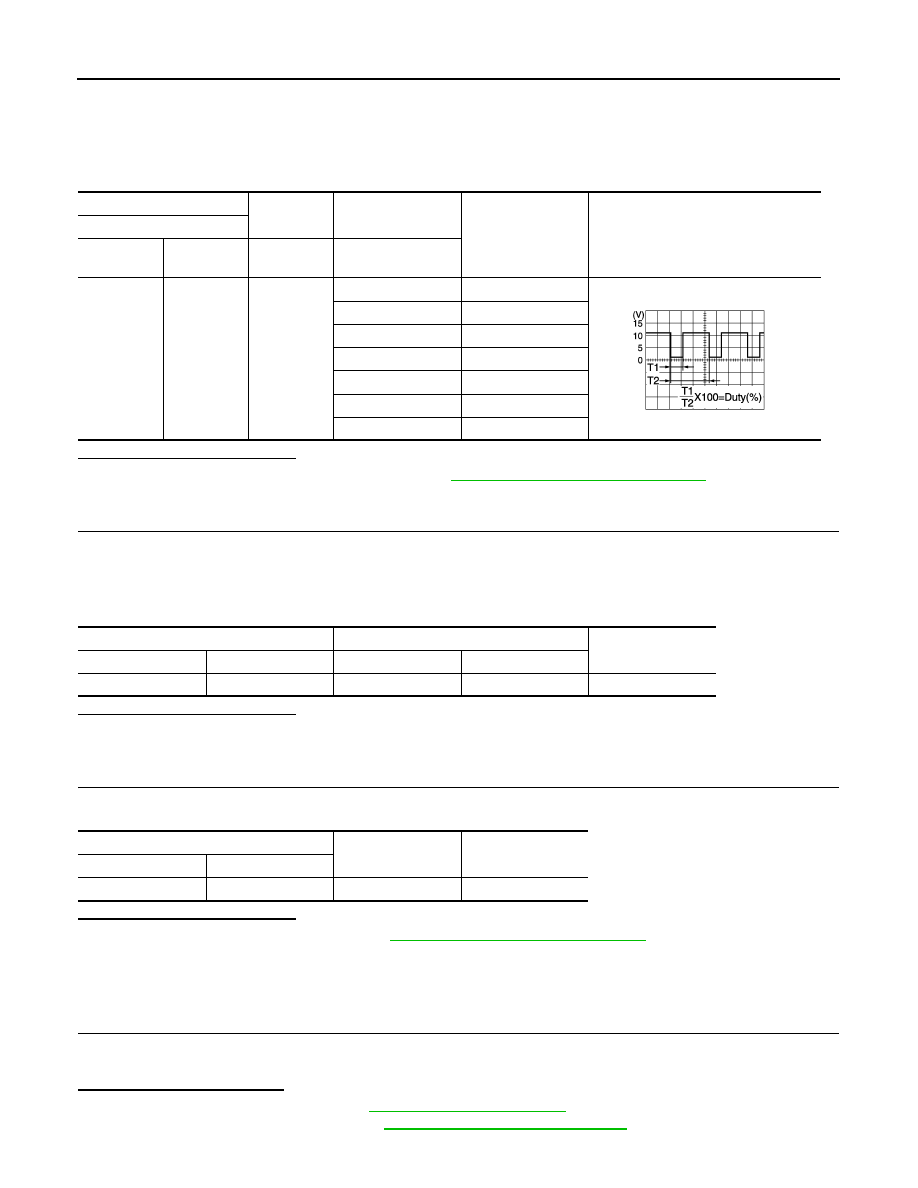

4. Change fan speed from 1st – 7th, and check duty ratios between variable blower control harness connec-

tor and ground by using an oscilloscope.

NOTE:

Calculate the drive signal duty ratio as shown in the figure.

T2 = Approx. 1.6 ms

Is the inspection result normal?

YES

>> Replace variable blower control. Refer to

HAC-113, "Removal and Installation"

.

NO

>> GO TO 10.

10.

CHECK VARIABLE BLOWER CONTROL CONTROL SIGNAL CIRCUIT FOR OPEN

1. Turn ignition switch OFF.

2. Disconnect variable blower control connector and A/C auto amp. connector.

3. Check continuity between variable blower control harness connector and A/C auto amp. harness connec-

tor.

Is the inspection result normal?

YES

>> GO TO 11.

NO

>> Repair harness or connector.

11.

CHECK VARIABLE BLOWER CONTROL CONTROL SIGNAL CIRCUIT FOR SHORT

Check continuity between variable blower control harness connector and ground.

Is the inspection result normal?

YES

>> Replace A/C auto amp. Refer to

HAC-105, "Removal and Installation"

.

NO

>> Repair harness or connector.

Component Inspection (Blower Motor)

INFOID:0000000009757688

1.

CHECK BLOWER MOTOR

1. Connect battery voltage to terminal 1 of blower motor.

2. Connect ground to terminal 2 of blower motor.

Does the blower fan operate?

YES

>> Intermittent incident. Refer to

GI-39, "Intermittent Incident"

.

NO

>> Replace blower motor. Refer to

VTL-10, "Removal and Installation"

.

+

−

Condition

Duty ratio

(Approx.)

Output waveform

Variable blower control

Connector

Terminal

Fan speed (manual)

Air outlet: VENT

M52

2

Ground

1st

26%

2nd

34%

3rd

41%

4th

51%

5th

62%

6th

73%

7th

82%

JPIIA1646GB

Variable blower control

A/C auto amp.

Continuity

Connector

Terminal

Connector

Terminal

M52

2

M34

13

Yes

Variable blower control

—

Continuity

Connector

Terminal

M52

2

Ground

No