Nissan Sentra. Manual - part 440

EC-456

< DTC/CIRCUIT DIAGNOSIS >

[MRA8DE]

IGNITION SIGNAL

IGNITION SIGNAL

Component Function Check

INFOID:0000000009758714

1.

INSPECTION START

1. Turn ignition switch OFF.

2. Start engine.

Does the engine start?

YES

>> GO TO 2.

NO

>> Proceed to

.

2.

IGNITION SIGNAL FUNCTION

With CONSULT

1. Perform “POWER BALANCE” in “ACTIVE TEST” mode of “ENGINE” using CONSULT.

2. Check that each circuit produces a momentary engine speed drop.

Without CONSULT

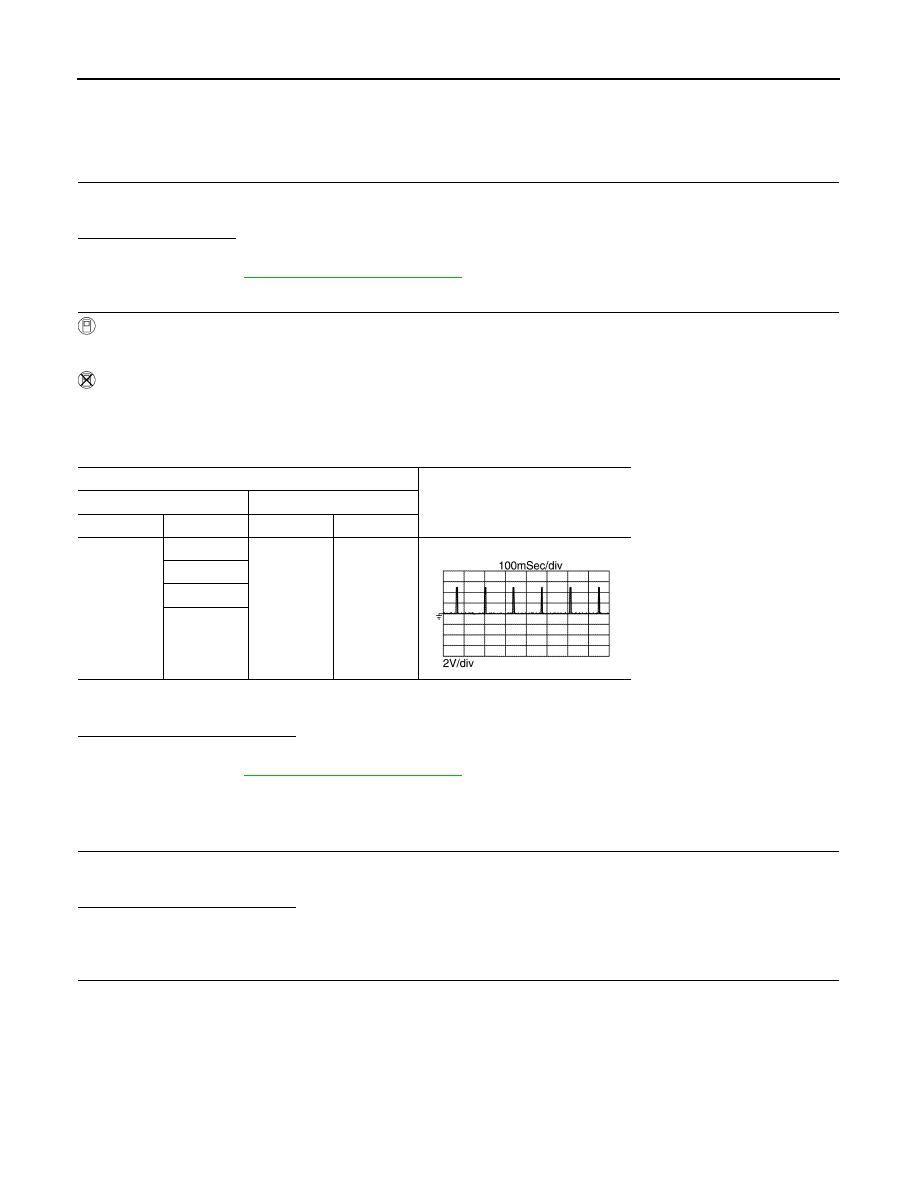

1. Let engine idle.

2. Check the voltage signal between ECM harness connector and ground with an oscilloscope.

NOTE:

The pulse cycle changes depending on rpm at idle.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Proceed to

.

Diagnosis Procedure

INFOID:0000000009758715

1.

CHECK FUSE

1. Turn ignition switch OFF.

2. Pull out #51 fuse and check that the fuse is not fusing.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Replace the fuse after repairing the applicable circuit.

2.

CHECK IGNITION COIL POWER SUPPLY

1. Insert the fuse which pulled out.

2. Disconnect ignition coil harness connector.

3. Turn ignition switch ON.

4. Check the voltage between ignition coil harness connector and ground.

ECM

Voltage signal

+

−

Connector

Terminal

Connector

Terminal

F25

86

E16

128

87

90

91

JPBIA4733ZZ