Nissan Sentra. Manual - part 419

EC-372

< DTC/CIRCUIT DIAGNOSIS >

[MRA8DE]

P1225 TP SENSOR

P1225 TP SENSOR

DTC Logic

INFOID:0000000009758623

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure

before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10 V at idle.

>> GO TO 2.

2.

PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Turn ignition switch ON.

4. Check 1st trip DTC.

Is 1st trip DTC detected?

YES

>> Proceed to

.

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000009758624

1.

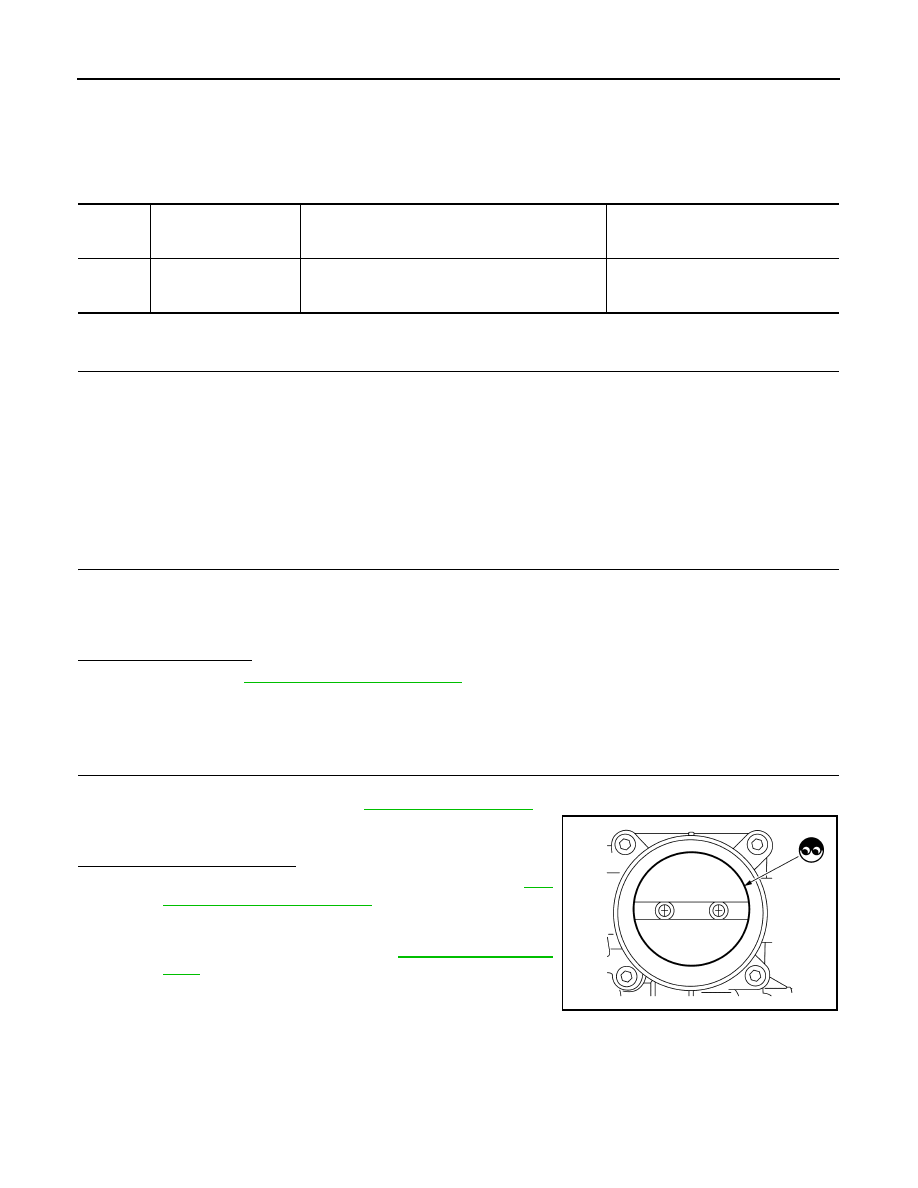

CHECK ELECTRIC THROTTLE CONTROL ACTUATOR VISUALLY

1. Turn ignition switch OFF.

2. Remove the intake air duct. Refer to

.

3. Check if foreign matter is caught between the throttle valve and

the housing.

Is the inspection result normal?

YES

>> Replace electric throttle control actuator. Refer to

27, "Removal and Installation"

.

NO

>> Remove the foreign matter and clean the electric throttle

control actuator inside, then perform throttle valve

closed position learning. Refer to

.

DTC No.

CONSULT screen terms

(Trouble diagnosis con-

tent)

DTC detecting condition

Possible cause

P1225

CTP LEARNING-B1

(Closed throttle position

learning bank 1)

Closed throttle position learning value is excessively

low.

Electric throttle control actuator

(TP sensor 1 and 2)

JSBIA2864ZZ