Nissan Sentra. Manual - part 368

EC-168

< DTC/CIRCUIT DIAGNOSIS >

[MRA8DE]

U0101 CAN COMM CIRCUIT

U0101 CAN COMM CIRCUIT

Description

INFOID:0000000009758422

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

DTC Logic

INFOID:0000000009758423

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON and wait at least 3 seconds.

2. Check DTC.

Is DTC detected?

YES

>> Proceed to

.

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000009758424

Perform the trouble diagnosis for CAN communication system. Refer to

LAN-16, "Trouble Diagnosis Flow

.

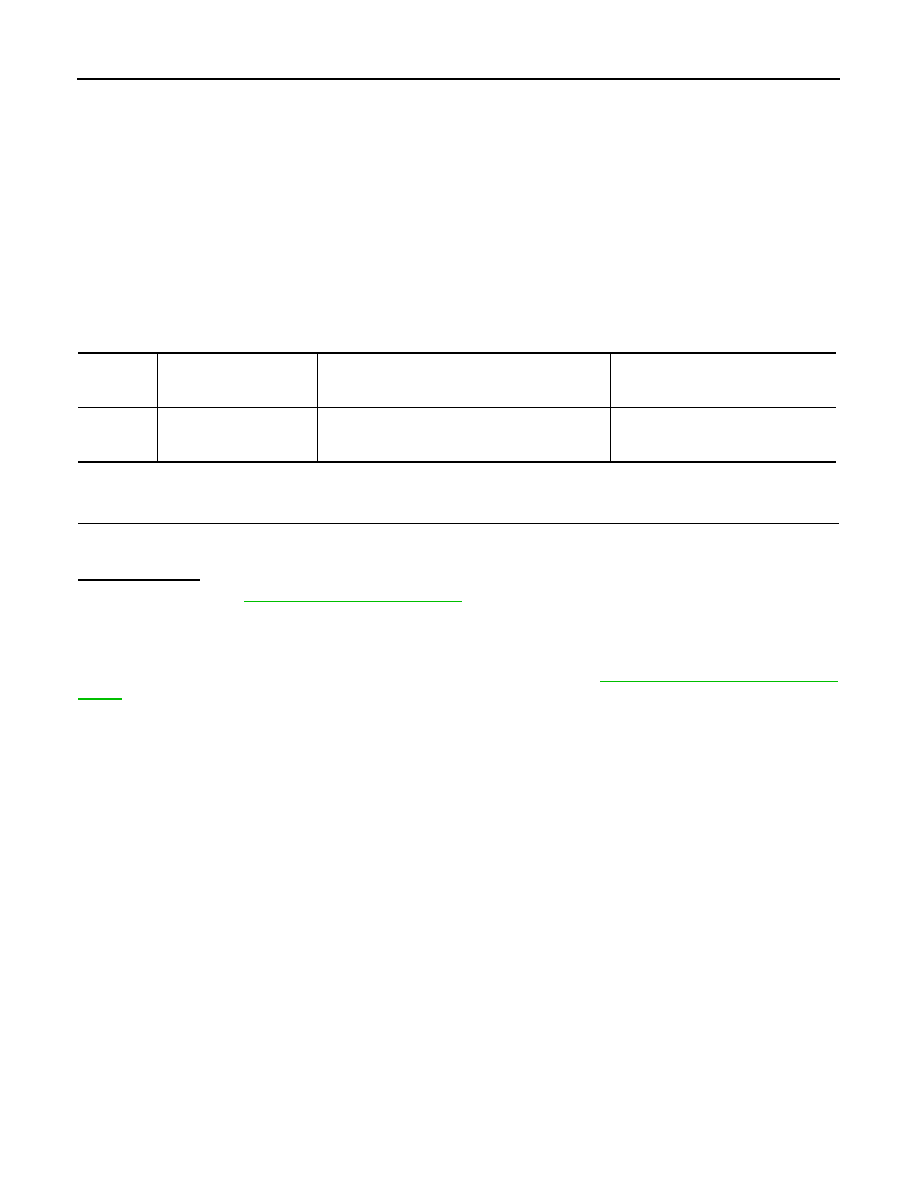

DTC No.

CONSULT screen terms

(Trouble diagnosis con-

tent)

DTC detecting condition

Possible cause

U0101

LOST COMM (TCM)

(Lost communication with

TCM)

When ECM is not transmitting or receiving CAN

communication signal of OBD (emission-related

diagnosis) with TCM for 2 seconds or more.

CAN communication line between

TCM and ECM