Nissan Sentra. Manual - part 289

DLK-272

< DTC/CIRCUIT DIAGNOSIS >

[WITHOUT INTELLIGENT KEY SYSTEM]

KEYFOB BATTERY AND FUNCTION

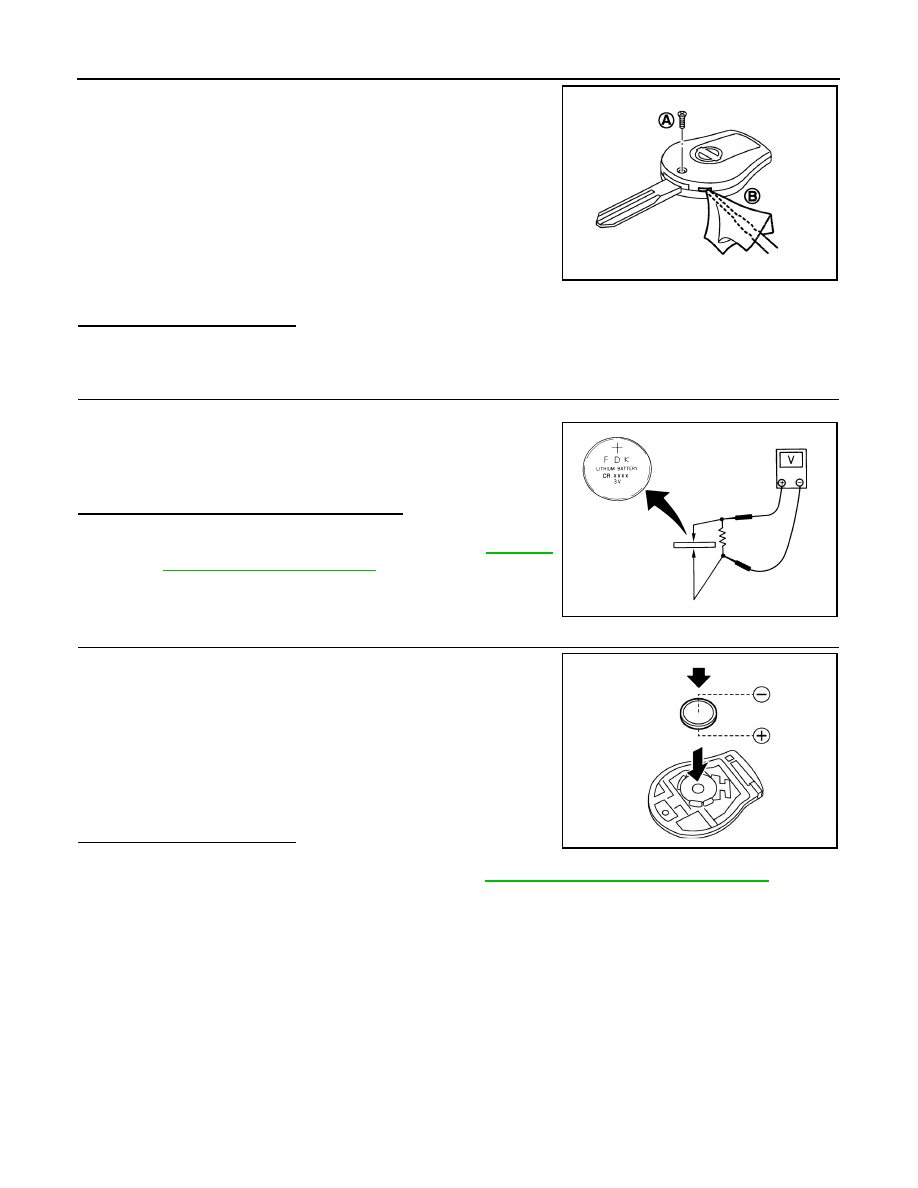

1. Remove the screw (A).

2. Insert a small screwdriver into the slit of the corner (B) and twist

it to separate the upper part from the power part. Use a cloth to

protect the casing.

CAUTION:

• Do not touch the circuit board or battery terminal.

• The keyfob is water-resistant. However, if it does get wet,

immediately wipe it dry.

3. Remove the keyfob battery.

CAUTION:

• Keep dirt, grease, and other foreign materials off the elec-

trode contact area.

4. Visually inspect keyfob internal components.

Is the inspection result normal?

YES

>> GO TO 3

NO

>> Repair or replace malfunctioning parts.

3.

CHECK KEYFOB BATTERY

Check by connecting a resistance (approximately 300

Ω) so that the

current value becomes about 10 mA.

Is the measurement value within specification?

YES

>> Keyfob battery is OK. Check remote keyless entry

receiver. Refer to

.

NO

>> GO TO 4

4.

REPLACE KEYFOB BATTERY

1. Replace the keyfob battery with a new one (CR1620 or equiva-

lent).

CAUTION:

• When replacing battery, keep dirt, grease, and other for-

eign materials off the electrode contact area.

• Make sure that the + side faces the bottom of the case.

2. Align the tips of the upper and lower parts, and then push them

together until it is securely closed.

3. After replacing the battery, check that all keyfob functions work

properly.

Is the inspection result normal?

YES

>> Keyfob is OK.

NO

>> Check remote keyless entry receiver. Refer to

DLK-268, "Component Function Check"

ALKIA2301ZZ

Standard

: Approx. 2.5 - 3.0V

OCC0607D

ALKIA2302ZZ