Nissan Leaf. Manual - part 899

LAN-58

< DTC/CIRCUIT DIAGNOSIS >

[CAN]

MAIN LINE BETWEEN INV/MC AND DLC CIRCUIT

MAIN LINE BETWEEN INV/MC AND DLC CIRCUIT

Diagnosis Procedure

INFOID:0000000010120380

1.

CHECK CONNECTOR

1. Turn the power switch OFF.

2. Disconnect the 12V battery cable from the negative terminal. Refer to

LAN-26, "Precautions for Removing

3. Check the following terminals and connectors for damage, bend and loose connection (connector side

and harness side).

-

Harness connector F2

-

Harness connector E60

-

Harness connector E105

-

Harness connector M77

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair the terminal and connector.

2.

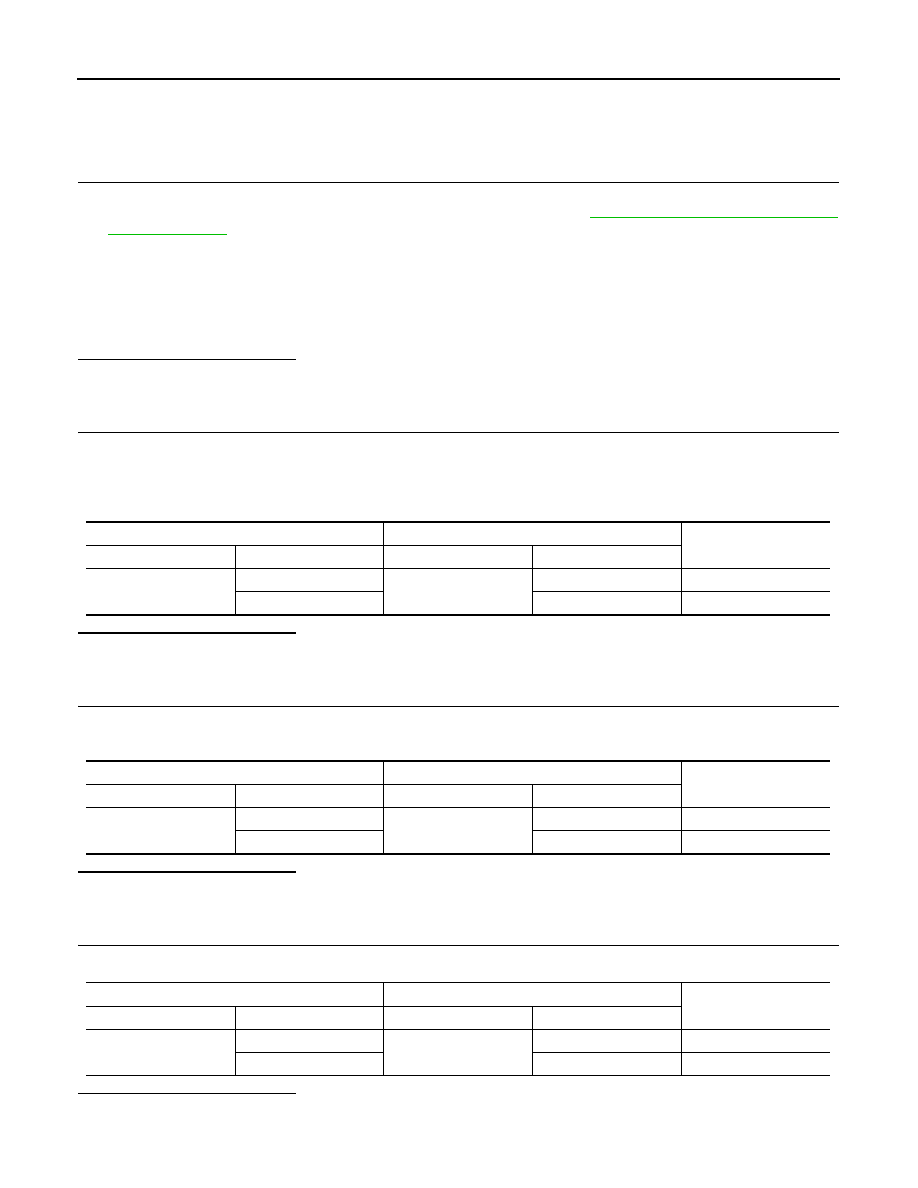

CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

1. Disconnect the following harness connectors.

-

Traction motor inverter

-

Harness connectors F2 and E60

2. Check the continuity between the traction motor inverter harness connector and the harness connector.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Repair the main line between the traction motor inverter and the harness connector F2.

3.

CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

1. Disconnect the harness connectors E105 and M77.

2. Check the continuity between the harness connectors.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair the main line between the harness connector E60 and the harness connector E105.

4.

CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

Check the continuity between the harness connector and the data link connector.

Is the inspection result normal?

YES (Present error)>>Check CAN system type decision again.

Traction motor inverter harness connector

Harness connector

Continuity

Connector No.

Terminal No.

Connector No.

Terminal No.

F13

14

F2

5

Existed

15

6

Existed

Harness connector

Harness connector

Continuity

Connector No.

Terminal No.

Connector No.

Terminal No.

E60

5

E105

50

Existed

6

49

Existed

Harness connector

Data link connector

Continuity

Connector No.

Terminal No.

Connector No.

Terminal No.

M77

50

M4

13

Existed

49

12

Existed