Nissan Leaf. Manual - part 827

B278C, B278D ELECTRIC COMPRESSOR

HAC-311

< DTC/CIRCUIT DIAGNOSIS >

[AUTO A/C (WITHOUT HEAT PUMP)]

C

D

E

F

G

H

J

K

L

M

A

B

HAC

N

O

P

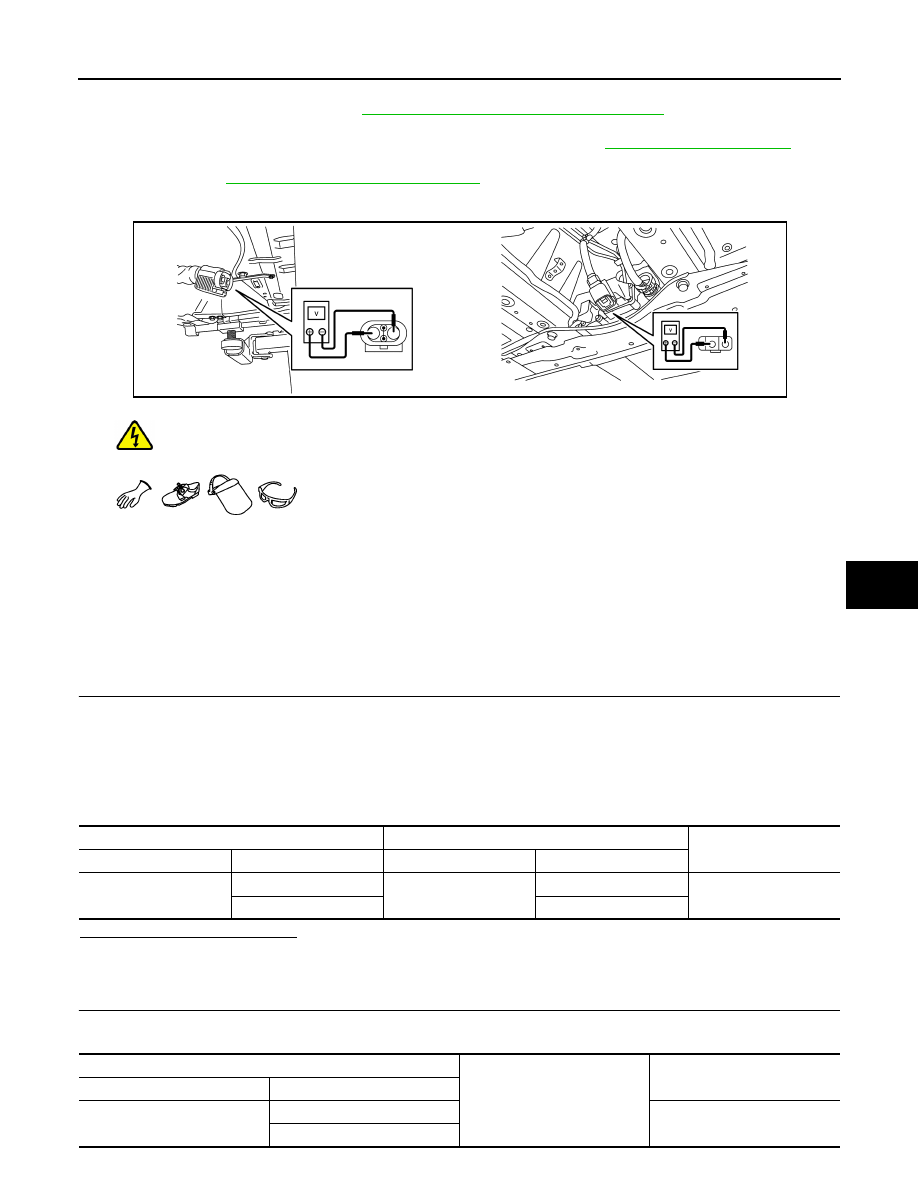

WARNING:

Disconnect the high voltage. Refer to

GI-33, "How to Disconnect High Voltage"

.

Check voltage in high voltage circuit. (Check that condenser are discharged.)

1. Lift up the vehicle and remove the Li-ion battery under covers. Refer to

2. Disconnect high voltage harness connector and PTC heater harness connector from front side of Li-ion

battery. Refer to

EVB-181, "Removal and Installation"

.

3. Measure voltage between high voltage harness connector terminals and PTC heater harness connector

terminals.

DANGER:

Touching high voltage components without using the appropriate protective equipment will

cause electrocution.

CAUTION:

For voltage measurements, use a tester which can measure to 500 V or higher.

>> GO TO 2.

2.

CHECK ELECTRIC COMPRESSOR COMMUNICATION LINE FOR OPEN

1. Turn power switch OFF.

2. Disconnect electric compressor and A/C auto amp. connector.

3. Check continuity between electric compressor harness connector and A/C auto amp. harness connector.

NOTE:

Check for any adhering foreign substances, cracking, or damage on the electric compressor terminal and

A/C auto amp. harness connector terminal.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Repair harness or connector.

3.

CHECK ELECTRIC COMPRESSOR COMMUNICATION LINE FOR SHORT

Check continuity between electric compressor harness connector and ground.

Standard

: 5 V or less

JPCIA0296ZZ

Electric compressor

A/C auto amp.

Continuity

Connector

Terminal

Connector

Terminal

F10

7

M55

14

Yes

9

18

Electric compressor

Ground

Continuity

Connector

Terminal

F10

7

No

9