Nissan Leaf. Manual - part 818

SYSTEM SETTING

HAC-275

< BASIC INSPECTION >

[AUTO A/C (WITHOUT HEAT PUMP)]

C

D

E

F

G

H

J

K

L

M

A

B

HAC

N

O

P

When the 12V battery cable is disconnected from the negative terminal or when the 12V battery voltage

becomes 10 V or less, the setting of the REC memory function may be cancelled.

Inlet Port Memory Function (FRE)

INFOID:0000000010121972

DESCRIPTION

• If the ignition switch is turned to the OFF position while the intake switch is set to OFF (fresh air intake), “Per-

form the memory” or “Do not perform the memory” of intake switch OFF (fresh air intake) condition can be

selected.

• If “Perform the memory” is set, the intake switch is OFF (fresh air intake) when turning the ignition switch to

the ON position again.

• If “Do not perform the memory” is set, the air inlets is controlled automatically when turning the ignition

switch to the ON position again.

HOW TO SET

With CONSULT

Perform the “FRE MEMORY SET” in “Work support” of “HVAC”.

NOTE:

When the 12V battery cable is disconnected from the negative terminal or when the 12V battery voltage

becomes 10 V or less, the setting of the FRE memory function may be cancelled.

Foot Position Setting Trimmer

INFOID:0000000010121973

DESCRIPTION

In FOOT mode, the air blowing to DEF can change ON/OFF.

HOW TO SET

With CONSULT

Perform the “BLOW SET” in “Work support” of “HVAC”.

NOTE:

When the 12V battery cable is disconnected from the negative terminal or when the 12V battery voltage

becomes 10 V or less, the setting of the discharge air mix ratio in FOOT mode may be cancelled.

Compressor Operation Setting at Defroster Mode (Timer/Remote Climate Control)

INFOID:0000000010121974

DESCRIPTION

For A/C-heater timer and remote climate control, change the setting of electric compressor operation during

DEF mode.

How to set

Using CONSULT, select “COMP OPRT SET AT DEF MODE (TIM/RMT CLIMT CONT)” in “Work support“ of

“HVAC”.

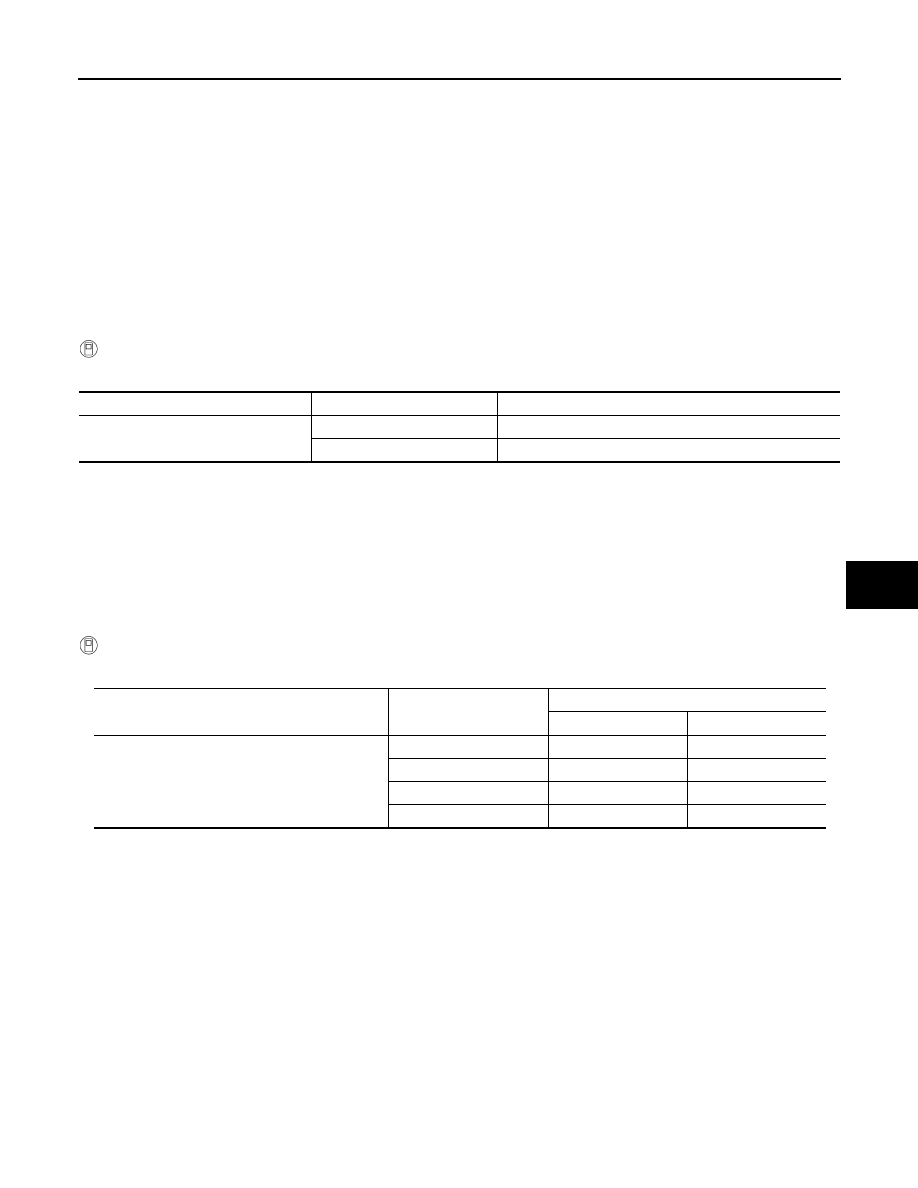

Work support items

Display

Setting

FRE MEMORY SET

WITHOUT

Perform the memory of manual FRE

WITH (initial status)

Do not perform the memory of manual FRE (auto control)

Work support items

Display

Defroster door position

Audio control

Manual control

BLOW SET

Mode1 (initial status)

OPEN

CLOSE

Mode2

OPEN

OPEN

Mode3

CLOSE

OPEN

Mode4

CLOSE

CLOSE