Nissan Leaf. Manual - part 739

HA-78

< SYSTEM DESCRIPTION >

[WITHOUT HEAT PUMP SYSTEM]

COMPONENT PARTS

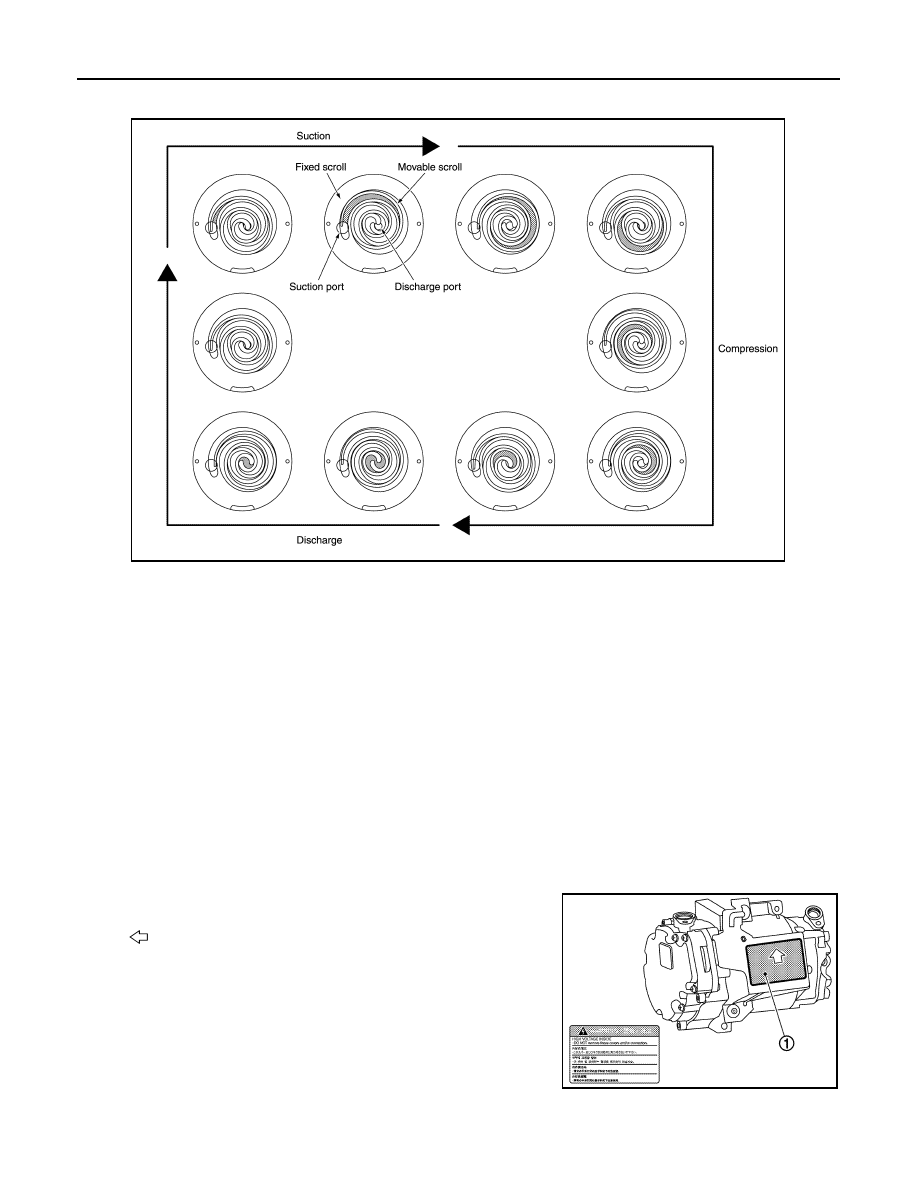

• A scroll-type compressor is used. The motor drive force is used to rotate the moveable scroll and perform

refrigerant intake, compression, and discharge.

Refrigerant and Compressor Oil

INFOID:0000000010122151

• The refrigerant is HFC-134a, which contains no chlorine (Cl), a substance which damages the ozone layer.

• The compressor oil is ND-OIL 11, an ester oil with high insulation performance, designed especially for elec-

tric compressors.

CAUTION:

• The special electric compressor oil has different properties from the conventional HFC-134a com-

pressor oil (PAG oil) and CFC-12 compressor oil (mineral oil). Be sure not to mix these oil types with

the compressor oil, as doing so may cause electric leakage.

NOTE:

• HFC: HydroFluoroCarbon

• CFC: ChloroFluoroCarbon

High Voltage Warning Label

INFOID:0000000010122152

• High voltage warning label is stuck on each component parts below.

• When replacing component parts make sure to stick it on original position.

Electric Compressor

The label (1) is stuck on the compressor stay.

PTC Heater

JSIIA1625GB

: Application direction of the label

JMIIA2629ZZ