Nissan Leaf. Manual - part 575

EVC-324

< DTC/CIRCUIT DIAGNOSIS >

P31D5 PRE-CHARGE RELAY

P31D5 PRE-CHARGE RELAY

DTC Logic

INFOID:0000000010120792

DTC DETECTION LOGIC

NOTE:

If DTC P31D5 is displayed with DTC P0AA2, P31D4, P31DB, or P31DD, perform diagnosis for DTC P0AA2,

P31D4, P31DB, or P31DD.

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

• Turn power switch OFF and wait at least 90 seconds.

CAUTION:

During this period, never perform vehicle handling such as opening and closing of doors. If some

kind of vehicle handling is performed, then wait another 90 seconds or more from the time of the

vehicle handling.

• Make sure that 12V battery voltage is 11 V or more.

>> GO TO 2.

2.

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

1. Set the vehicle to READY and perform test drive.

2. Turn power switch OFF and wait at least for 60 seconds.

3. Check self-diagnostic result.

Is DTC detected?

YES

>> Proceed to

EVC-324, "Diagnosis Procedure"

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000010120793

DANGER:

Since hybrid vehicles and electric vehicles contain a high voltage battery, there is the risk of

electric shock, electric leakage, or similar accidents if the high voltage component and vehicle are

handled incorrectly. Be sure to follow the correct work procedures when performing inspection and

maintenance.

WARNING:

• Be sure to remove the service plug in order to disconnect the high voltage circuits before perform-

ing inspection or maintenance of high voltage system harnesses and parts.

• To prevent the removed service plug from being connected by mistake during the procedure, always

carry it in your pocket or put it in the tool box.

• Be sure to wear insulating protective equipment consisting of glove, shoes, face shield and glasses

before beginning work on the high voltage system.

• Clearly identify the persons responsible for high voltage work and ensure that other persons do not

touch the vehicle. When not working, cover high voltage parts with an insulating cover sheet or sim-

ilar item to prevent other persons from contacting them.

• Refer to

EVC-10, "High Voltage Precautions"

CAUTION:

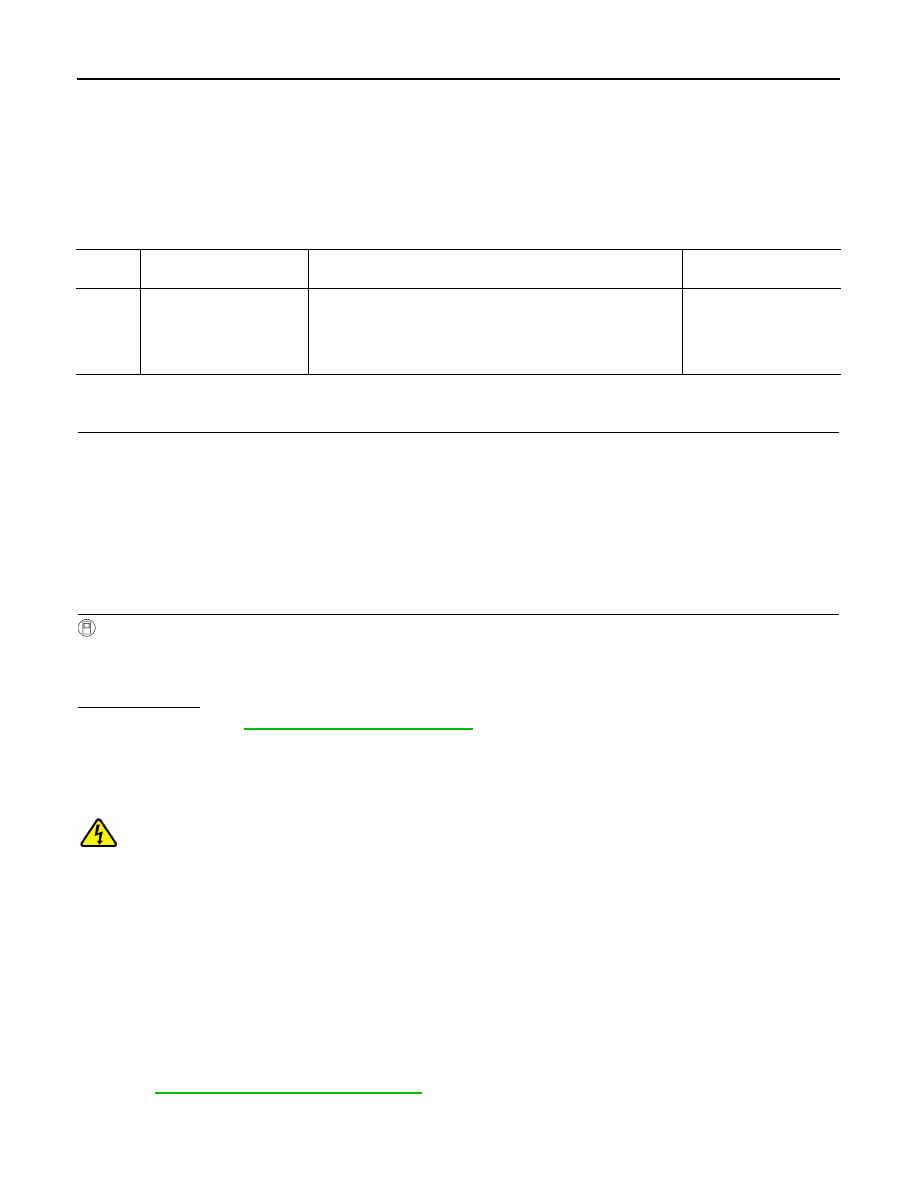

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P31D5

PRE CHARGE RELAY

(Pre-charge relay)

• The voltage of the traction motor inverter is 100 V or more im-

mediately before starting charging or immediately before

READY.

• The voltage of the traction motor inverter is 100 V or more

when only the system main relay 2 is ON.

• Harness or connectors

• Battery J/B

• Traction motor inverter

• VCM