Nissan Leaf. Manual - part 466

P33E6 CELL CONTROLLER

EVB-147

< DTC/CIRCUIT DIAGNOSIS >

D

E

F

G

H

I

J

K

L

M

A

B

EVB

N

O

P

P33E6 CELL CONTROLLER

DTC Logic

INFOID:0000000010121150

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

1. Turn power switch ON and wait for 10 seconds or more.

2. Select “Self Diagnostic Result” of “HV BAT”.

3. Check DTC.

Is P33E6 detected?

YES

>> Refer to

EVB-147, "Diagnosis Procedure"

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000010121151

DANGER:

Since hybrid vehicles and electric vehicles contain a high voltage battery, there is the risk of

electric shock, electric leakage, or similar accidents if the high voltage component and vehicle are

handled incorrectly. Be sure to follow the correct work procedures when performing inspection and

maintenance.

WARNING:

• Be sure to remove the service plug in order to disconnect the high voltage circuits before perform-

ing inspection or maintenance of high voltage system harnesses and parts.

• The removed service plug must always be carried in a pocket of the responsible worker or placed in

the tool box during the procedure to prevent the plug from being connected by mistake.

• Be sure to wear insulating protective equipment consisting of glove, shoes, face shield and glasses

before beginning work on the high voltage system.

• Never allow workers other than the responsible person to touch the vehicle containing high voltage

parts. To keep others from touching the high voltage parts, these parts must be covered with an insu-

lating sheet except when using them.

• Refer to

EVB-7, "High Voltage Precautions"

.

CAUTION:

Never bring the vehicle into the READY status with the service plug removed unless otherwise

instructed in the Service Manual. A malfunction may occur if this is not observed.

1.

CHECK SELF-DIAGNOSIS RESULTS OF LI-ION BATTERY CONTROLLER

With CONSULT

1. Select “Self Diagnostic Result” of “HV BAT”.

2. Check to see if “P0A1F”, “P3062” or “P33ED” is detected simultaneously with “P33E6”.

Is P0A1F, P3062 or P33ED detected?

YES-1 >> When “P0A1F” or “P3062” are detected simultaneously, Replace Li-ion battery controller. Refer to

EVB-181, "Removal and Installation"

YES-2 >> When “P33ED” is detected simultaneously, perform the diagnosis procedure of “P33ED”. Refer to

EVB-156, "Diagnosis Procedure"

NO

>> GO TO 2.

2.

CHECK FREEZE FRAME DATA (FFD)

With CONSULT

1. Check “FFD” when DTC is detected.

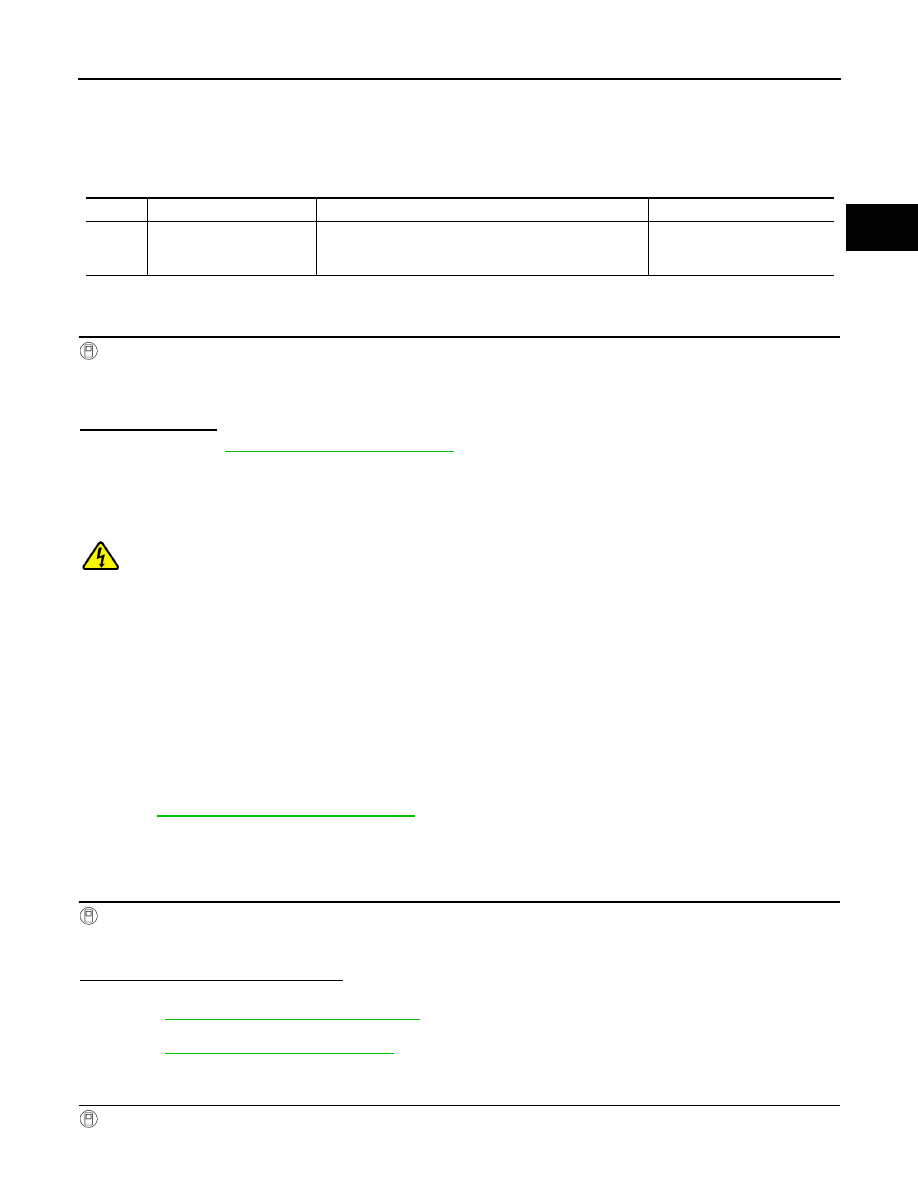

DTC

Trouble diagnosis name

DTC detecting condition

Possible causes

P33E6

CELL CONTROLLER

With the power switch ON and no load condition, the dif-

ference between the maximum voltage and minimum volt-

age exceeds the allowable range.

• Li-ion battery controller

• Module