Nissan Leaf. Manual - part 435

SYSTEM

EVB-23

< SYSTEM DESCRIPTION >

D

E

F

G

H

I

J

K

L

M

A

B

EVB

N

O

P

DESCRIPTION

The Li-ion battery controller (LBC) monitors the status of the inside of the Li-ion battery at all times and sends

information, such as the charging status of Li-ion battery and possible power, to VCM (vehicle control module)

via EV system CAN communication.

The Li-ion battery controller performs control as per the following.

• Monitors the battery state and transfers chargeable/dischargeable power to VCM to prevent an error, such

as overvoltage, over discharge or excessive temperature rise in the battery.

• Detects an error (overvoltage, over discharge, overcurrent, or excessive temperature rise) immediately at

the time of error occurrence and requests VCM to disconnect the system main relay to interrupt the dis-

charge/charge line.

• Maintains the optimum battery state constantly with a cell capacity adjustment function to prevent a reduc-

tion in charging/discharging capacity caused by cell capacity variations.

• Detects the connector fit state with the function to detect the fit of the high voltage harness connector and

transfers the detected state to VCM so that the vehicle does not start with an unsteady state.

• Detects the insulation resistance state with the function to detect the insulation resistance between high and

low voltage and transfers the detected state to VCM so that the vehicle does not start with an unusual state.

• Estimates a battery charge state and low battery state, based on the data obtained with the battery state

detection function, and reflects on the battery capacity meter.

BATTERY PROTECTION

The Li-ion battery has a voltage range capable of charge/discharge. If charged/discharged exceeding the

range, excessive low capacity or malfunction may be caused. To prevent this, the Li-ion battery controller

detects voltage of each cell and requests the control of charging/discharging energy to VCM so that the cell

voltage stays within the voltage range.

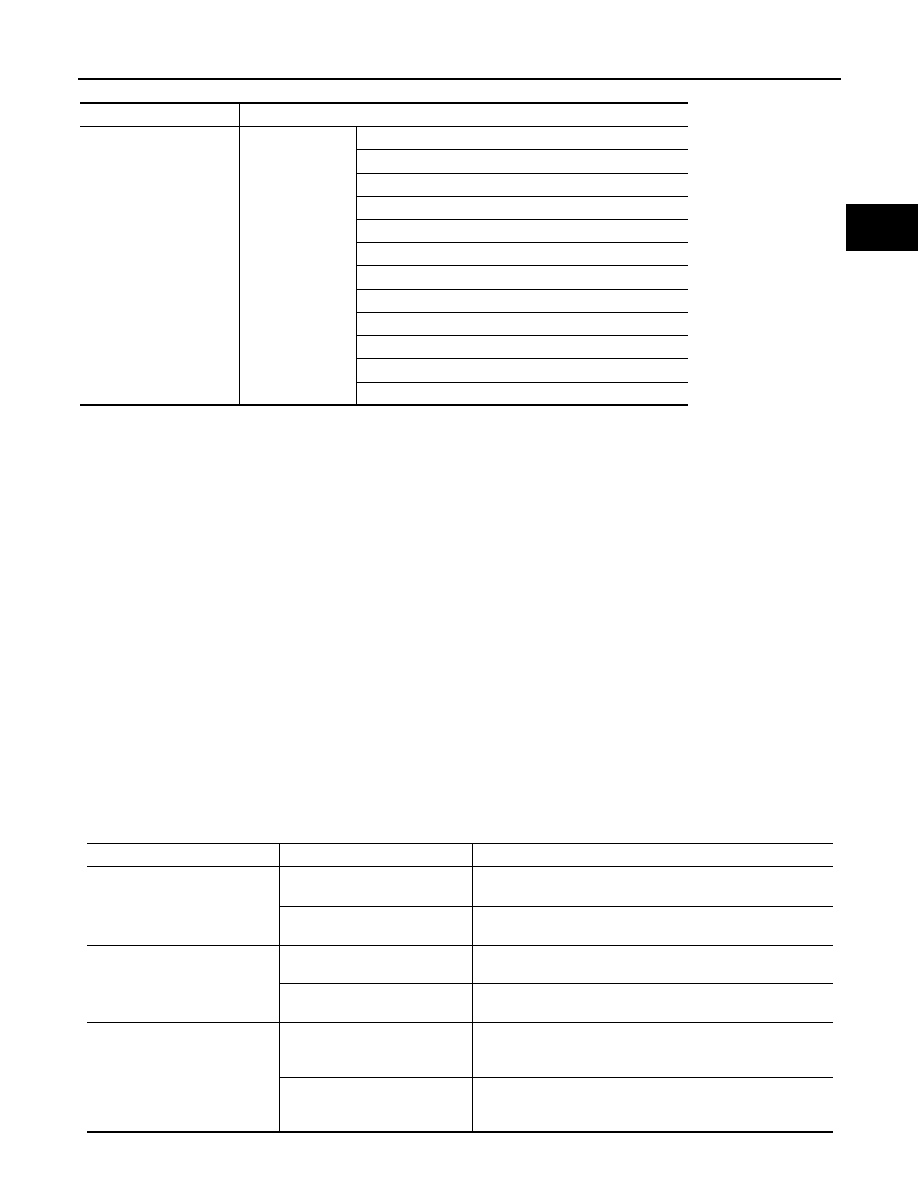

Received unit

Signal name

VCM

EV system CAN

High voltage discharge permit signal

Li-ion battery main relay cut request signal

Li-ion battery connector interlock signal

Li-ion battery voltage signal

Li-ion battery current signal

Li-ion battery chargeable power signal

Li-ion battery dischargeable power signal

Li-ion battery chargeable completion signal

Li-ion battery available charge signal

Li-ion battery capacity signal

Li-ion battery gradual capacity loss signal

Insulation resistance signal

Control item

Control

Operating condition

Overvoltage/overcurrent protec-

tion

Charging energy control

Gradual control of charging energy as the cell voltage ap-

proaches the upper limit of the voltage capable of charging.

System main relay cut

Cell voltage exceeds the voltage judged as overvoltage and

maintains the voltage for more than the specified time.

Over discharge protection

Discharging energy control

Gradual control of discharging energy as the cell voltage ap-

proaches the lower limit of the voltage capable of discharging.

System main relay cut

Cell voltage exceeds the voltage judged as over discharge and

maintains the voltage for more than the specified time.

Excessive temperature rise pro-

tection

Charging/discharging energy

control

Gradual control of charging/discharging energy as Li-ion bat-

tery temperature approaches the upper limit of the temperature

capable of use.

System main relay cut

Li-ion battery temperature exceeds the temperature judged as

excessive temperature rise and maintains the temperature for

more than the specified time.