Nissan Leaf. Manual - part 174

SYSTEM

BR-17

< SYSTEM DESCRIPTION >

C

D

E

G

H

I

J

K

L

M

A

B

BR

N

O

P

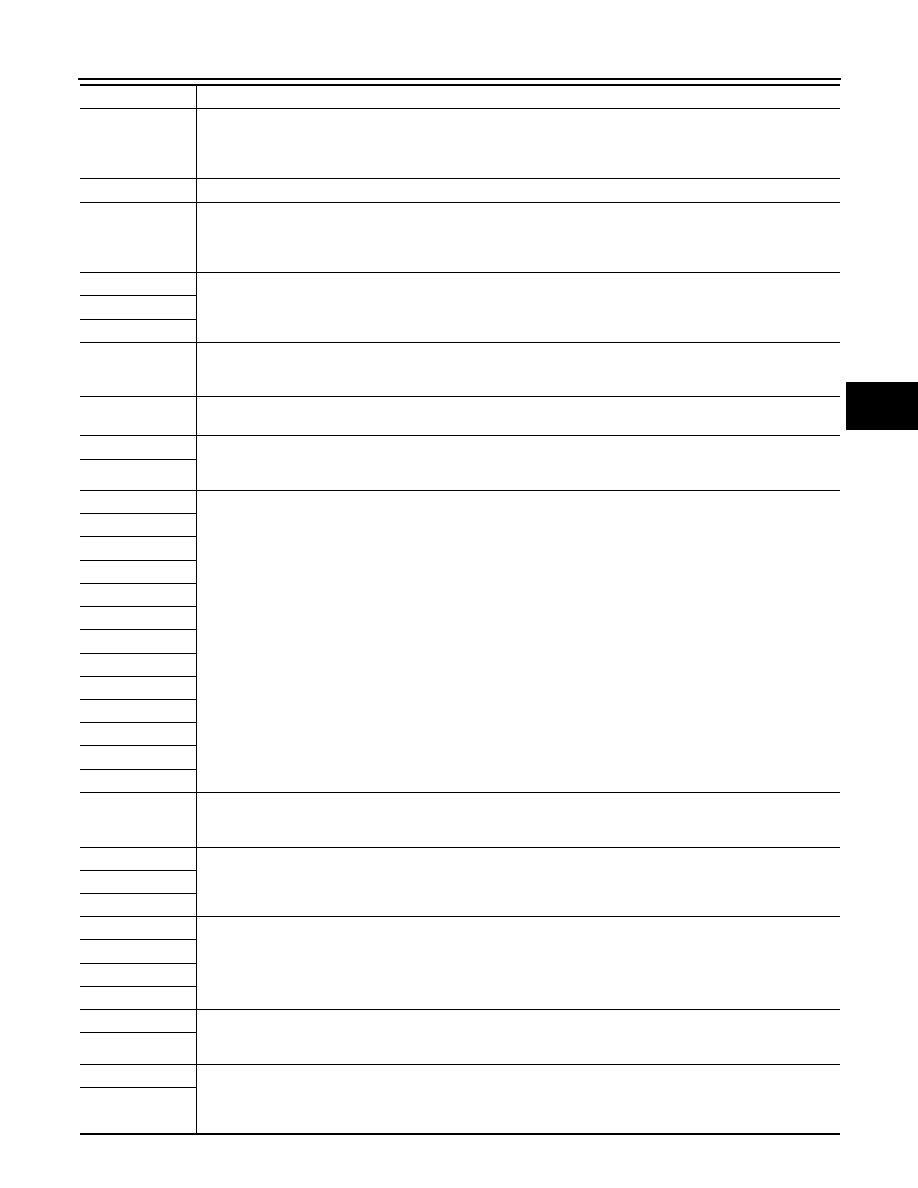

C1A65

The following functions are suspended.

• Boost operation by the electrically-driven intelligent brake

• Cooperative regenerative brake control

• Power supply from the brake power supply backup unit

C1A67

Normal control

C1A69

The following functions are suspended.

• Boost operation by the electrically-driven intelligent brake

• Cooperative regenerative brake control

• Power supply from the brake power supply backup unit

C1A6B

The following function is suspended.

• Backup power supply from the brake power supply backup unit

C1A6C

C1A6D

C1A6E

The following function is suspended.

• Cooperative regenerative brake control

• hill start assist function

C1A6F

The following function is suspended.

• hill start assist function

C1A70

The following function is suspended.

• Cooperative regenerative brake control

• hill start assist function

C1A74

C1A80

The following functions are suspended.

• Boost operation by the electrically-driven intelligent brake

• Cooperative regenerative brake control

• Power supply from the brake power supply backup unit

C1A81

C1A82

C1A83

C1A84

C1A85

C1A86

C1A87

C1A88

C1A89

C1A8A

C1A8B

C1A90

C1A91

The following function is suspended.

• Cooperative regenerative brake control

• hill start assist function

C1A98

The following function is suspended.

• Power supply from the brake power supply backup unit

C1A99

C1A9A

C1AA0

The following functions are suspended.

• Boost operation by the electrically-driven intelligent brake

• Cooperative regenerative brake control

• Power supply from the brake power supply backup unit

C1AA1

C1AA2

C1AA3

C1AA9

The following function is suspended.

• Cooperative regenerative brake control

• hill start assist function

C1AB8

C1AB9

The following functions are suspended.

• Boost operation by the electrically-driven intelligent brake

• Cooperative regenerative brake control

• Power supply from the brake power supply backup unit

C1ABA

DTC

Vehicle condition