Content .. 1192 1193 1194 1195 ..

Nissan Leaf. Manual - part 1194

P0A8D 14VOLT POWER VOLTAGE

TMS-57

< DTC/CIRCUIT DIAGNOSIS >

D

E

F

G

H

I

J

K

L

M

A

B

TMS

N

O

P

P0A8D 14VOLT POWER VOLTAGE

DTC Logic

INFOID:0000000010120942

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always power switch OFF and wait

at least 10 seconds before conducting the next test.

>> GO TO 2.

2.

CHECK DTC DETECTION

With CONSULT

1. Power switch ON and wait 10 seconds or more.

2. Check DTC.

Is “P0A8D” detected?

YES

>> Go to

.

NO-1 >> To check malfunction symptom before repair: Refer to

GI-53, "Intermittent Incident"

NO-2 >> Confirmation after repair: INSPECTION END

Diagnosis Procedure

INFOID:0000000010120943

1.

CHECK TRACTION MOTOR INVERTER HARNESS CONNECTOR

1. Power switch OFF.

2. Check the connection conditions of the traction motor inverter harness connector.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace damaged parts.

2.

CHECK POWER SUPPLY CIRCUIT

1. Disconnect the traction motor inverter harness connector.

2. Check the 10A fuse (#74).

3. Power switch ON.

4. Check the voltage between traction motor inverter vehicle side harness connector terminals.

Is the inspection result normal?

YES

>> Replace the traction motor inverter. Refer to

TMS-103, "Removal and Installation"

.

NO

>> Check the M/C relay. Refer to

EVC-371, "Diagnosis Procedure"

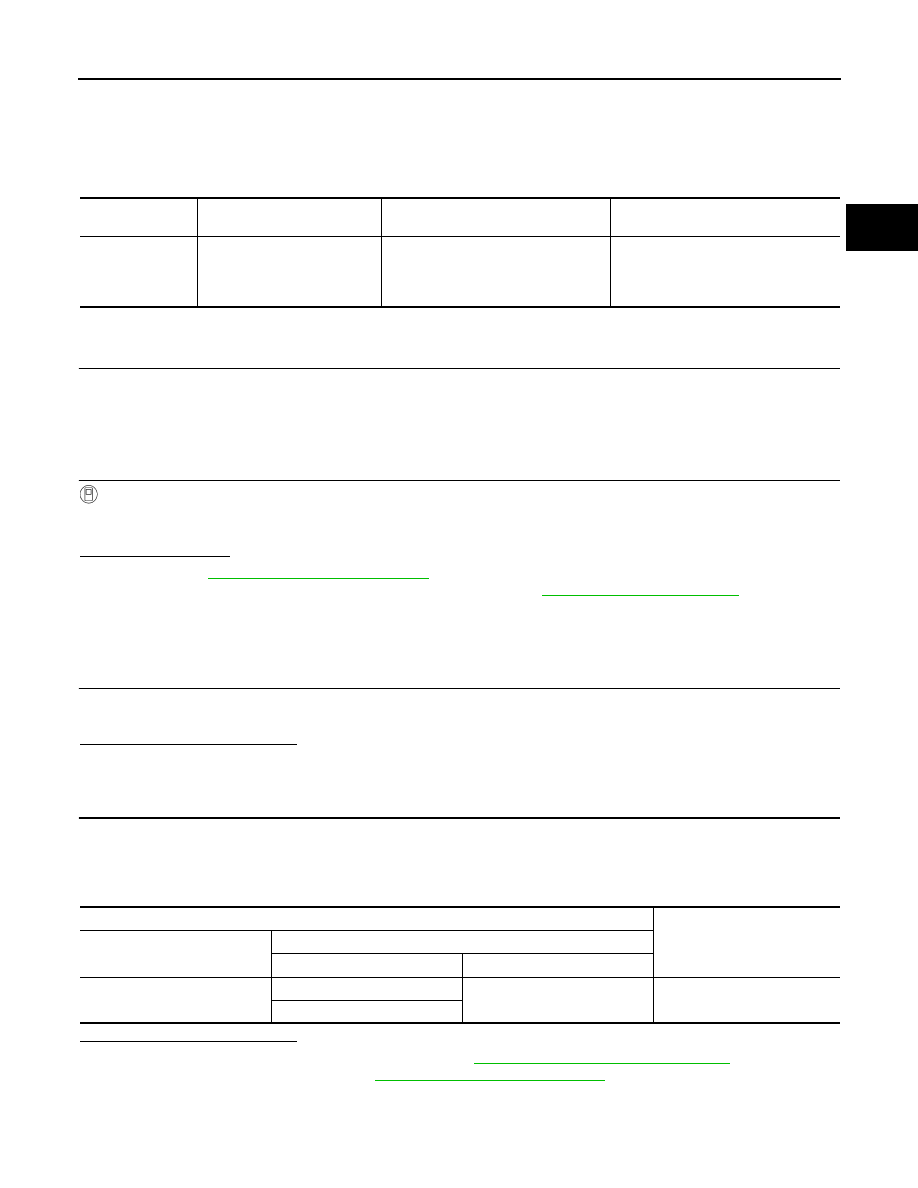

DTC

CONSULT screen terms

(Trouble diagnosis content)

Malfunction detected condition

Possible causes

P0A8D

14VOLT POWER VOLTAGE

(14 Volt Power Module System

Voltage Low)

The voltage of 12V battery drops to ap-

prox. 8 V or less

• Harness, fuse, or connectors

(Each circuit is open or shorted.)

• Traction motor inverter

• M/C relay

Traction motor inverter

Voltage

Connector

Terminal

+

−

F13

46

47, 49

9 – 16 V

48