Content .. 1162 1163 1164 1165 ..

Nissan Leaf. Manual - part 1164

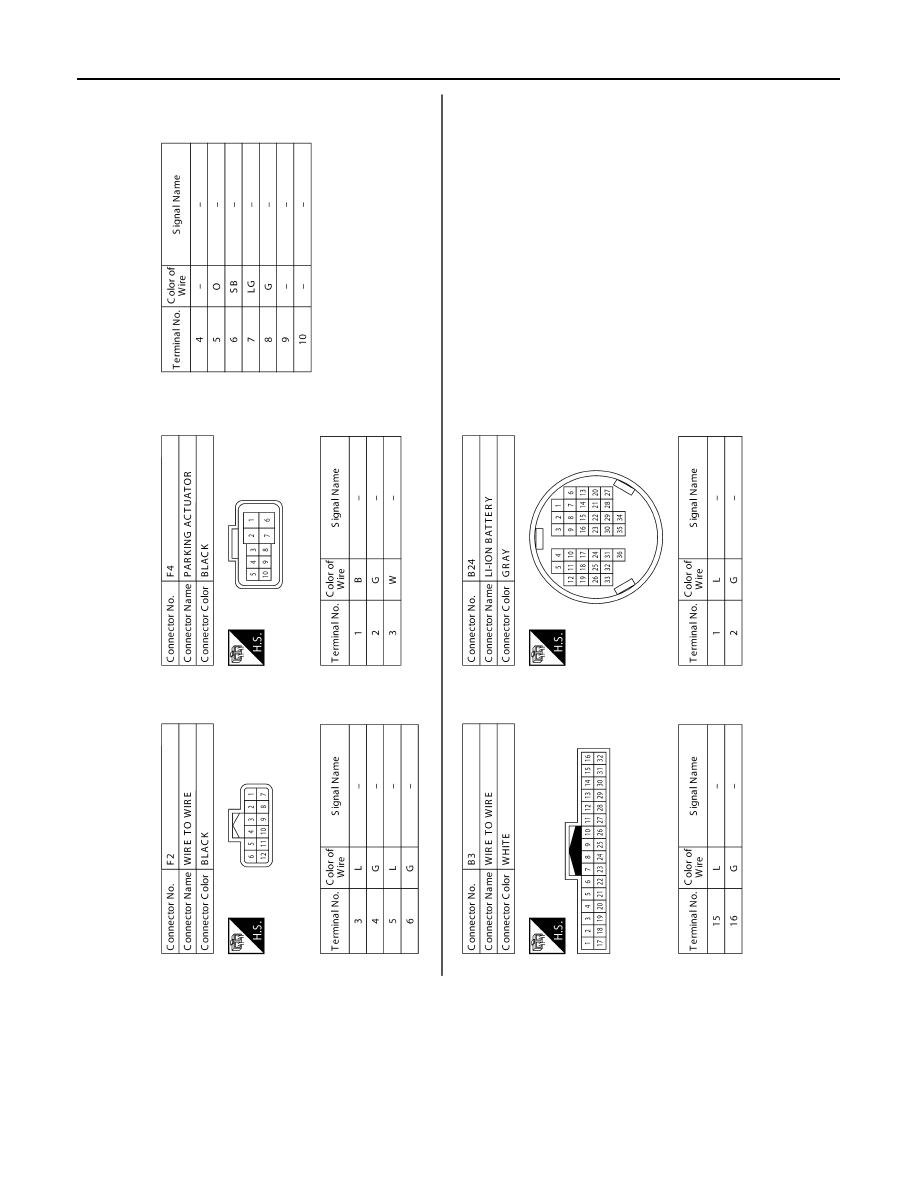

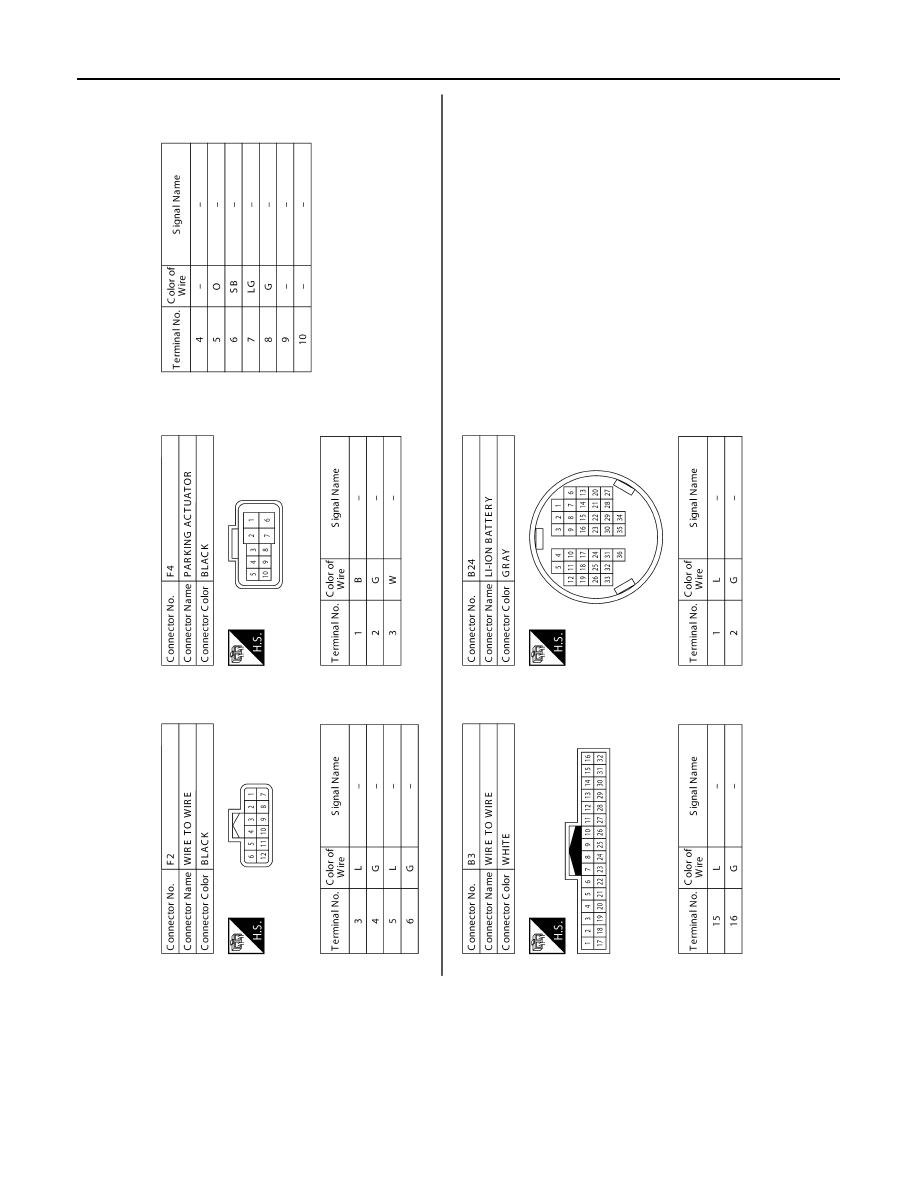

TM-62

< WIRING DIAGRAM >

[ELECTRIC SHIFT]

ELECTRIC SHIFT SYSTEM

AADIA0754GB

|

|

|

Content .. 1162 1163 1164 1165 ..

TM-62 < WIRING DIAGRAM > [ELECTRIC SHIFT] ELECTRIC SHIFT SYSTEM AADIA0754GB |