Content .. 1073 1074 1075 1076 ..

Nissan Leaf. Manual - part 1075

SEC-62

< BASIC INSPECTION >

[WITH INTELLIGENT KEY SYSTEM]

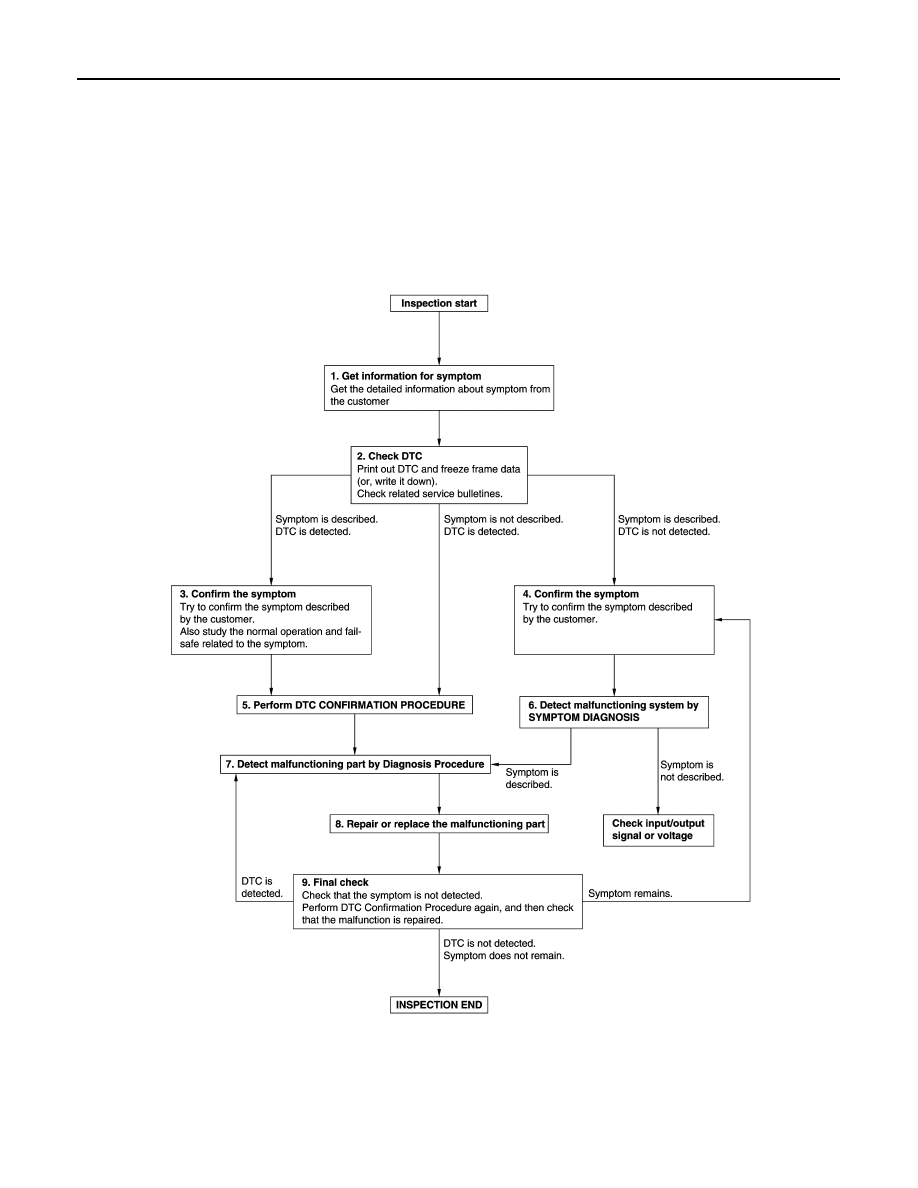

DIAGNOSIS AND REPAIR WORK FLOW

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORK FLOW

Work Flow

INFOID:0000000010119241

OVERALL SEQUENCE

DETAILED FLOW

JMKIA8652GB