Content .. 1040 1041 1042 1043 ..

Nissan Leaf. Manual - part 1042

REAR SHOCK ABSORBER

RSU-9

< REMOVAL AND INSTALLATION >

C

D

F

G

H

I

J

K

L

M

A

B

RSU

N

O

P

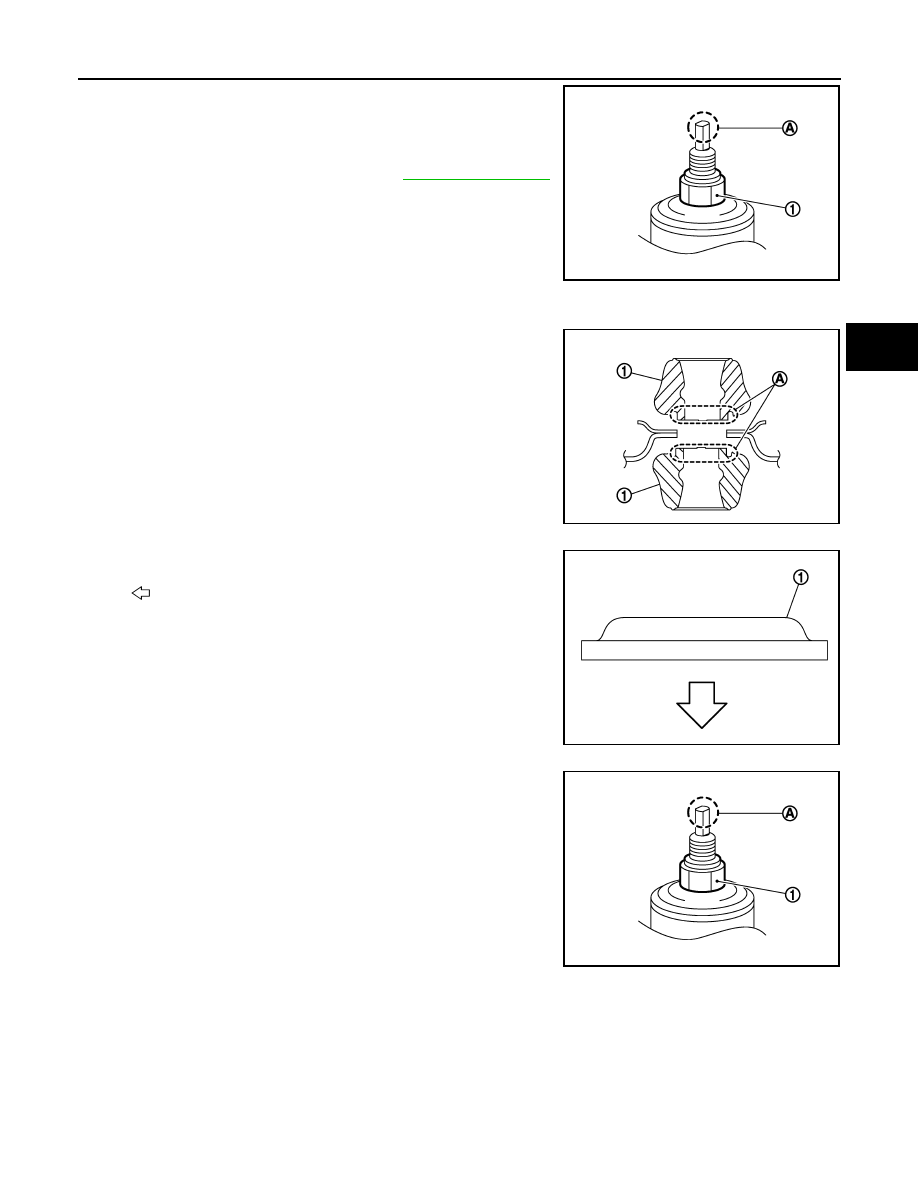

To loosen piston rod lock nut (1), fix the tip (A) of the piston rod.

7. Remove shock absorber assembly.

8. Remove bushing, distance tube, washer, bound bumper cover,

and bound bumper from shock absorber.

9. Perform inspection after removal. Refer to

INSTALLATION

Note the following, and install in the reverse order of removal.

• To install bushings (1), securely insert protrusion (A) into the hole

on the vehicle body side.

• Install washer (1) in the direction shown.

• Perform final tightening of bolts and nuts at the shock absorber

lower side (rubber bushing), under unladen conditions with tires on

level ground.

• Hold a head (A) of shock absorber piston rod not to have it rotate,

then tighten the piston rod lock nut (1) to the specified torque.

CAUTION:

Do not reuse piston rod lock nut.

JPEIB0241ZZ

JPEIB0240ZZ

: Bushing side

JPEIB0248ZZ

JPEIB0241ZZ