Nissan Frontier D22. Manual - part 862

PS-8

ON-VEHICLE SERVICE

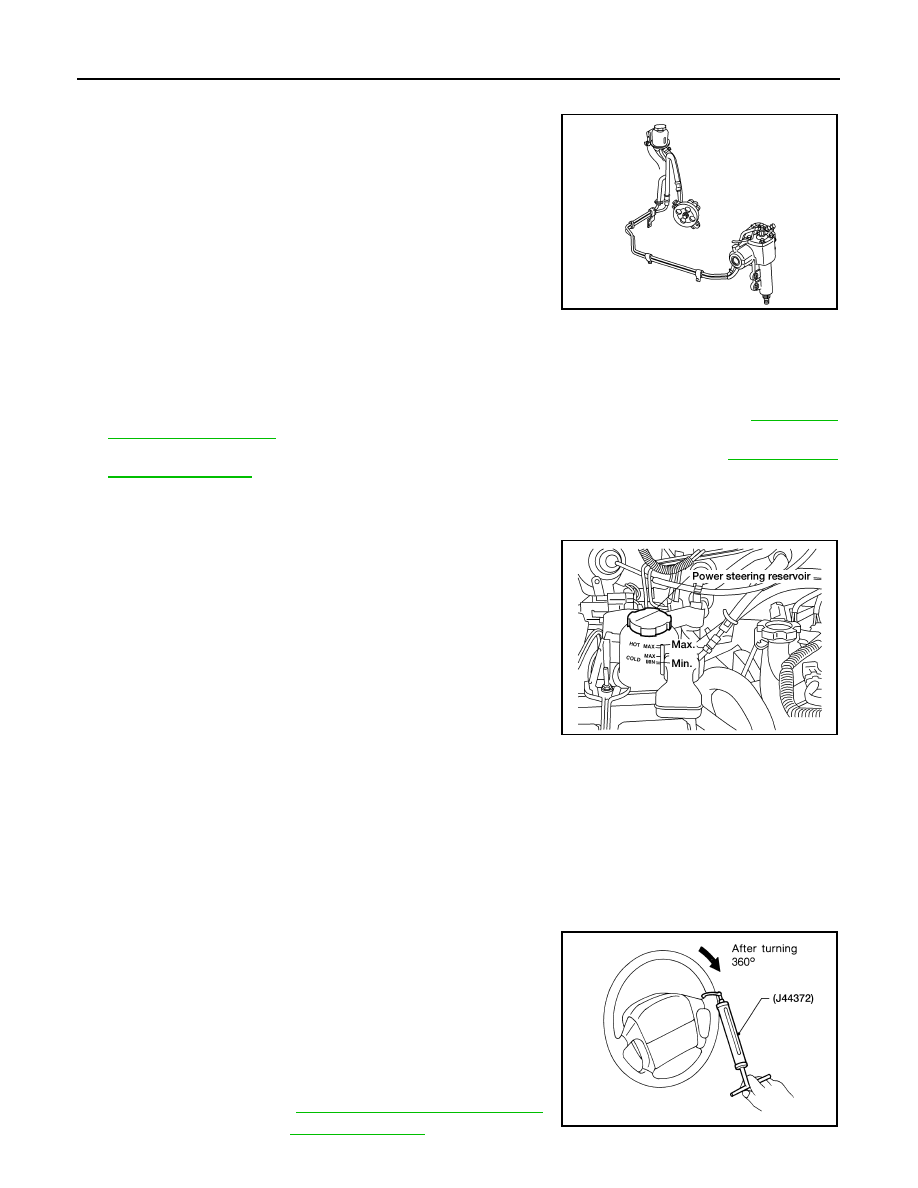

Checking Fluid Leakage

EGS000L4

Check lines for improper attachment, leaks, cracks, damage, chafing

and deterioration.

1.

Run engine between idle speed and 1,000 rpm.

2.

Bring power steering fluid up to adequate operating tempera-

ture. [Make sure temperature of fluid is approximately 60 to

80

°C (140 to 176°F).]

3.

Turn steering wheel right-to-left several times.

4.

Hold steering wheel at each “lock” position for 5 seconds and

carefully check for fluid leakage.

CAUTION:

Do not hold steering wheel at lock position for more than 15

seconds.

5.

If fluid leakage from any line is noticed, loosen flare nut and then retighten.

CAUTION:

Do not overtighten connector as this can damage O-ring, washer and connector.

6.

If fluid leakage from power steering pump is noticed, check power steering oil pump. Refer to

7.

If fluid leakage from power steering gear is noticed, check power steering gear. Refer to

.

Bleeding Hydraulic System

EGS000L5

1.

Raise front end of vehicle until wheels are clear of the ground.

2.

Add fluid to reservoir tank to specified level. Quickly turn steer-

ing wheel fully to right and left and lightly touch steering stop-

pers.

Repeat steering wheel operation until fluid level no longer

decreases.

3.

Start engine.

Repeat step 2 above.

●

Incomplete air bleeding will cause the following to occur:

–

Air bubbles in reservoir tank

–

Clicking noise in power steering pump

–

Excessive buzzing in power steering pump

When this happens, bleed air again.

Fluid noise may occur in the valve or power steering pump. This is common when the vehicle is stationary or

while turning the steering wheel slowly. This does not affect the performance or durability of the system.

Checking Steering Wheel Turning Force

EGS000L6

1.

Park vehicle on a level, dry surface and set parking brake.

2.

Start engine and run at idle speed or 1,000 rpm.

3.

Bring power steering fluid up to adequate operating temperature. [Make sure temperature of fluid is

approximately 60 to 80

°C (140 to 176°F).]

4.

Check steering wheel turning force when steering wheel has

been turned 360

° from neutral position.

NOTE:

Tires need to be inflated to normal pressure.

5.

If steering wheel turning force is out of specification, check the

following:

a.

Hydraulic system. Refer to

PS-9, "Checking Hydraulic System"

.

b.

Steering column. Refer to

AST255

AST253

Steering wheel turning

force

: 39 N (4 kg, 9 lb) or less

WST049