Nissan Frontier D22. Manual - part 664

SERVICE DATA AND SPECIFICATIONS (SDS)

EC-1759

[VG33ER]

C

D

E

F

G

H

I

J

K

L

M

A

EC

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

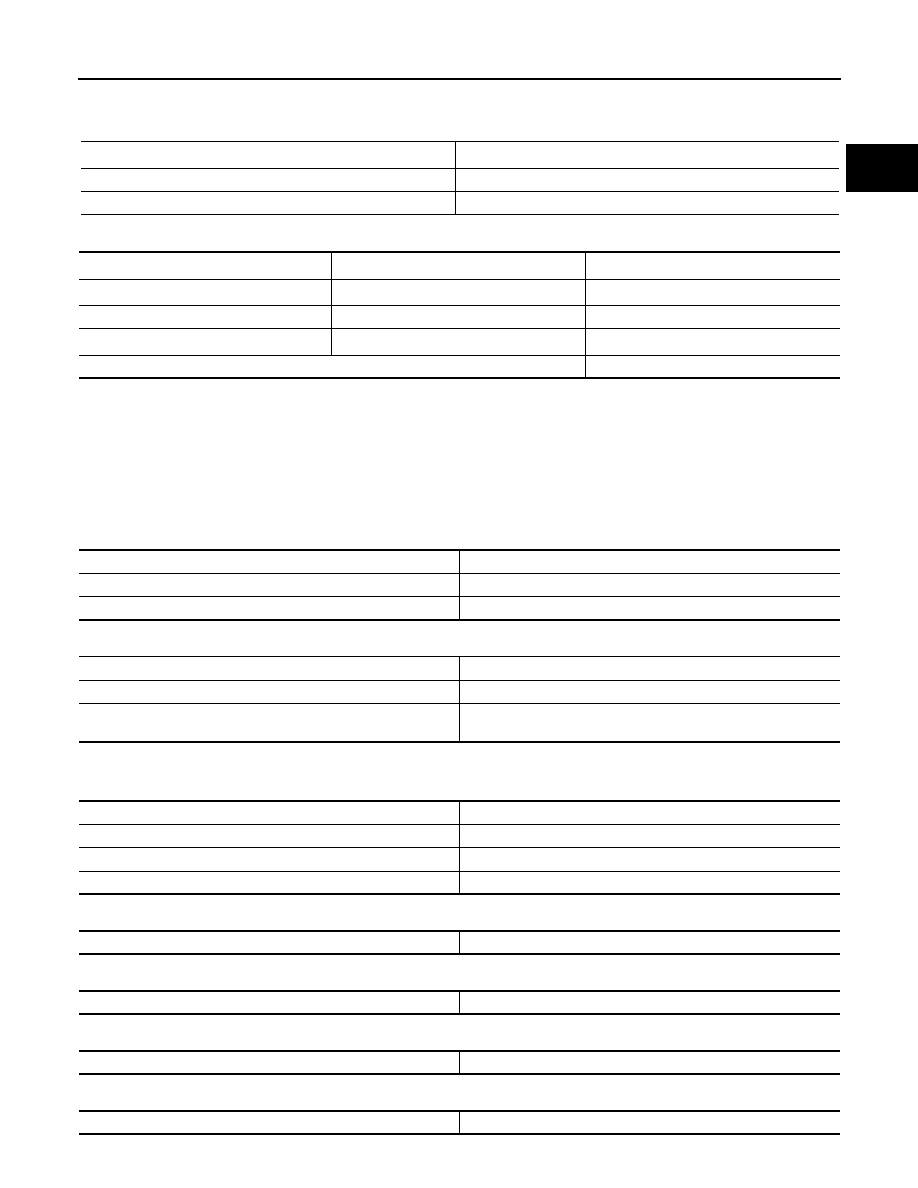

Fuel Pressure Regulator

UBS00E3E

Idle Speed and Ignition Timing

UBS00E3F

*1: Throttle position sensor harness connector disconnected or using CONSULT-II “WORK SUPPORT” mode

*2: Throttle position sensor harness connector connected

*3: Throttle position sensor harness connector disconnected

*4: Under the following conditions:

●

Air conditioner switch: OFF

●

Electric load: OFF (Lights, heater fan & rear window defogger)

●

Steering wheel: Kept in straight-ahead position

Ignition Coil

UBS00E3G

Mass Air Flow Sensor

UBS00E3H

*: Engine is warmed up to normal operating temperature and running under no-load.

Engine Coolant Temperature Sensor

UBS00E3I

Heated Oxygen Sensor 1 Heater

UBS00E3J

Fuel Pump

UBS00E3K

IACV-AAC Valve

UBS00E3L

Injector

UBS00E3M

Fuel pressure at idling kPa (kg/cm

2

, psi)

Vacuum hose is connected

Approximately 235 (2.4, 34)

Vacuum hose is disconnected

Approximately 294 (3.0, 43)

Base idle speed*

1

No-load*

4

(in P or N position)

700

±50 rpm

Target idle speed*

2

No-load*

4

(in P or N position)

750

±50 rpm

Air conditioner: ON

In P or N position

850 rpm or more

Ignition timing*

3

In P or N position

10

°±5° BTDC

Throttle position sensor idle position

0.15 - 0.85V

Primary voltage

12V

Primary resistance [at 20

°C (68°F)]

Approximately 1.0

Ω

Secondary resistance [at 20

°C (68°F)]

Approximately 10 k

Ω

Supply voltage

Battery voltage (11 - 14)V

Output voltage at idle

1.0 - 1.7*V

Mass air flow (Using CONSULT-II or GST)

3.3 - 4.8

g·m/sec at idle*

12.0 - 14.9

g·m/sec at 2,500 rpm*

Temperature

°C (°F)

Resistance k

Ω

20 (68)

2.1 - 2.9

50 (122)

0.68 - 1.00

90 (194)

0.236 - 0.260

Resistance [at 25

°C (77°F)]

2.3 - 4.3

Ω

Resistance [at 25

°C (77°F)]

0.2 - 5.0

Ω

Resistance [at 20

°C (68°F)]

Approximately 10.0

Ω

Resistance [at 25

°C (77°F)]

10 - 14

Ω