Nissan Frontier D22. Manual - part 633

DTC P1217 ENGINE OVER TEMPERATURE (OVERHEAT)

EC-1635

[VG33ER]

C

D

E

F

G

H

I

J

K

L

M

A

EC

5.

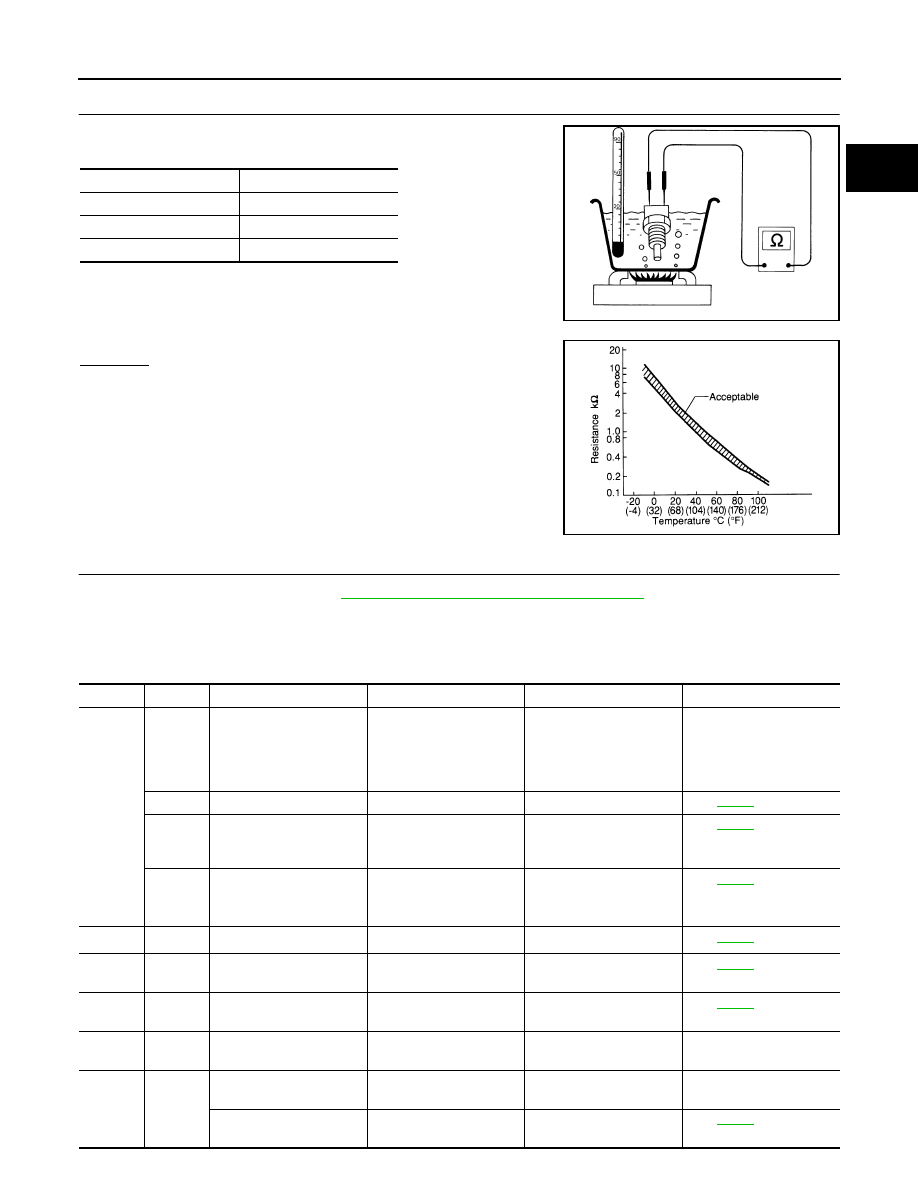

CHECK ENGINE COOLANT TEMPERATURE SENSOR

Check resistance as shown in the figure.

<Reference data>

OK or NG

OK

>> GO TO 6.

NG

>> Replace engine coolant temperature sensor.

6.

CHECK MAIN 12 CAUSES

If the cause cannot be isolated, go to

EC-1635, "Main 12 Causes of Overheating"

>> INSPECTION END.

Main 12 Causes of Overheating

UBS00E0R

Temperature

°C (°F)

Resistance k

Ω

20 (68)

2.1 - 2.9

50 (122)

0.68 - 1.00

90 (194)

0.236 - 0.260

SEF152P

SEF012P

Engine

Step

Inspection item

Equipment

Standard

Reference page

OFF

1

●

Blocked radiator

●

Blocked condenser

●

Blocked radiator grille

●

Blocked bumper

●

Visual

No blocking

—

2

●

Coolant mixture

●

Coolant tester

50 - 50% coolant mixture

See

3

●

Coolant level

●

Visual

Coolant up to MAX level

in reservoir tank and radi-

ator filler neck

See

4

●

Radiator cap

●

Pressure tester

59 - 98 kPa

(0.6 - 1.0 kg/cm

2

, 9 - 14

psi) (Limit)

See

ON*

1

5

●

Coolant leaks

●

Visual

No leaks

See

ON*

1

6

●

Thermostat

●

Touch the upper and

lower radiator hoses

Both hoses should be hot

See

ON*

1

7

●

Cooling fan (crank-

shaft driven)

●

Visual

Operating

See

OFF

8

●

Combustion gas leak

●

Color checker chemical

tester 4 Gas analyzer

Negative

—

ON*

2

9

●

Coolant temperature

gauge

●

Visual

Gauge less than 3/4

when driving

—

●

Coolant overflow to

reservoir tank

●

Visual

No overflow during driv-

ing and idling

See