Nissan Frontier D22. Manual - part 598

DTC P0441 EVAP CONTROL SYSTEM

EC-1495

[VG33ER]

C

D

E

F

G

H

I

J

K

L

M

A

EC

6.

CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

With CONSULT-II

1.

Start engine.

2.

Perform “PURG VOL CONT/V” in “ACTIVE TEST” mode with

CONSULT-II. Check that engine speed varies according to the

valve opening.

If OK, inspection end. If NG, go to following step.

3.

Check air passage continuity.

If NG, replace the EVAP canister purge volume control solenoid

valve.

OK or NG

OK

>> GO TO 8.

NG

>> Replace EVAP canister purge volume control solenoid

valve.

7.

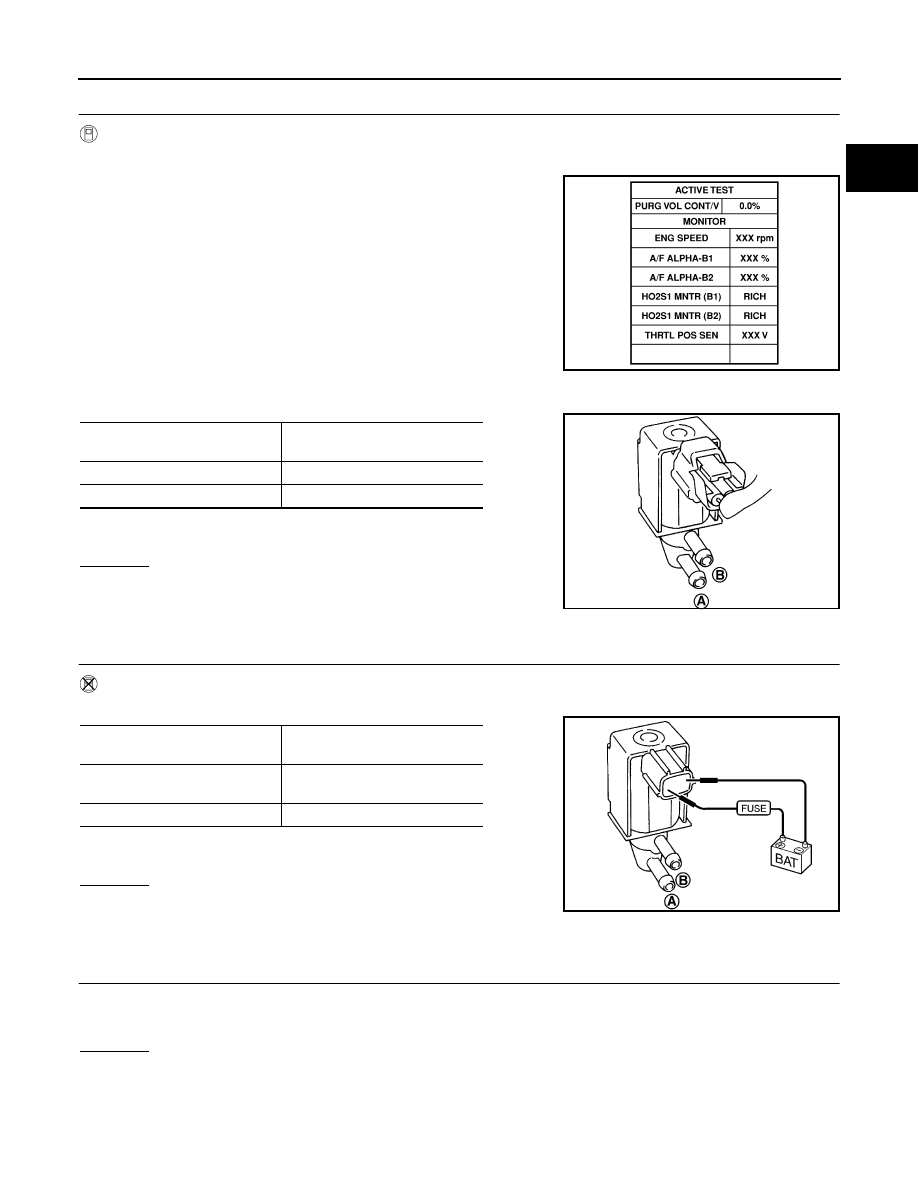

CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

Without CONSULT-II

Check air passage continuity.

If NG, replace the EVAP canister purge volume control solenoid

valve.

OK or NG

OK

>> GO TO 8.

NG

>> Replace EVAP canister purge volume control solenoid

valve.

8.

CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR HOSE

1.

Turn ignition switch OFF.

2.

Check disconnection or improper connection of hose connected to EVAP control system pressure sensor.

OK or NG

OK

>> GO TO 9.

NG

>> Repair it.

SEF985Y

Condition

PURG VOL CONT/V value

Air passage continuity between A

and B

100%

Yes

0%

No

SEF660U

Condition

Air passage continuity between A

and B

12V direct current supply

between terminals 1 and 2

Yes

No supply

No

SEF661U